Codes and standards for energy conservation

IgCC approach to thermal values

Instead of including tables of thermal values for roofs and walls, the 2012 IgCC incorporates specific instruments for calculating these above-code values. To accomplish this, the code’s Section 605.1.1 provides the following instructions:

The building thermal envelope shall exceed the requirements of Tables C402.2 and C402.1.2 of the IECC by not less than 10 percent. Specifically, for purposes of compliance with this code, each U-Factor, C-Factor, F-Factor, and K-Factor in the specified tables shall be reduced by 10 percent to determine the prescriptive criteria for this code.

Although this instruction is reasonably straightforward, it is important to note R-value (or R-factor) is not mentioned. Instead, the mathematical reciprocal of R-value (U-value or U-factor) is referenced. This means to identify the minimum R-value for a roof or wall assembly under IgCC, the designer must first identify the minimum U-value in the 2012 IECC for the roof or wall assembly in question, reduce it by 10 percent, and then calculate the reciprocal R-value.

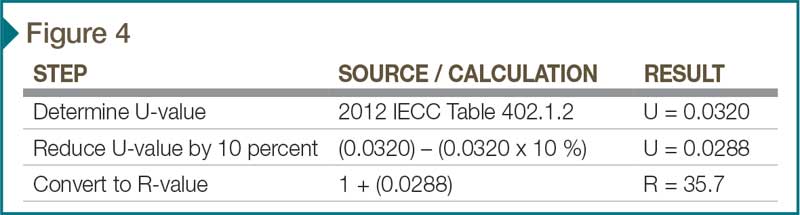

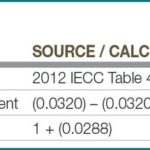

As an example, in the case of the Climate Zone 6, the minimum U-value for a roof with insulation above the deck in Table 402.1.2 of the 2012 IECC is 0.0320. Applying the 10 percent prescribed reduction results in a new IgCC U-value of 0.0288. Finally, converting the IgCC U-value of 0.0288 into its reciprocal R-value results in an IgCC R-value of 35.7. Figure 4 helps to illustrate a detail of the calculation.

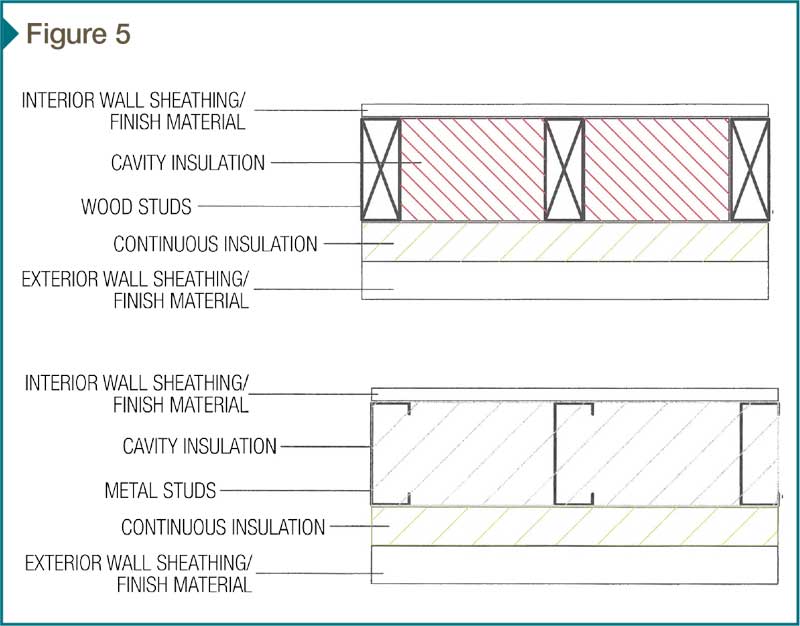

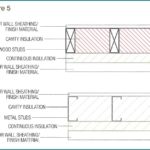

For a wall or roof assembly with insulation located only in one place within the assembly, calculating the appropriate IgCC R-values is relatively simple, although it can be a little confusing initially. However, for walls or roofs with insulation located in more than one place within the assembly, things may become more difficult. As an example, wood-framed and metal-framed walls in almost all of the climate zones now require two separate locations for insulation:

- installed within the wall cavity

(i.e. between the wood and/or metal studs); and - installed on the wall’s exterior side.

Figure 5 illustrates examples of cavity insulation and continuous insulation in wood- and metal-framed walls alike.

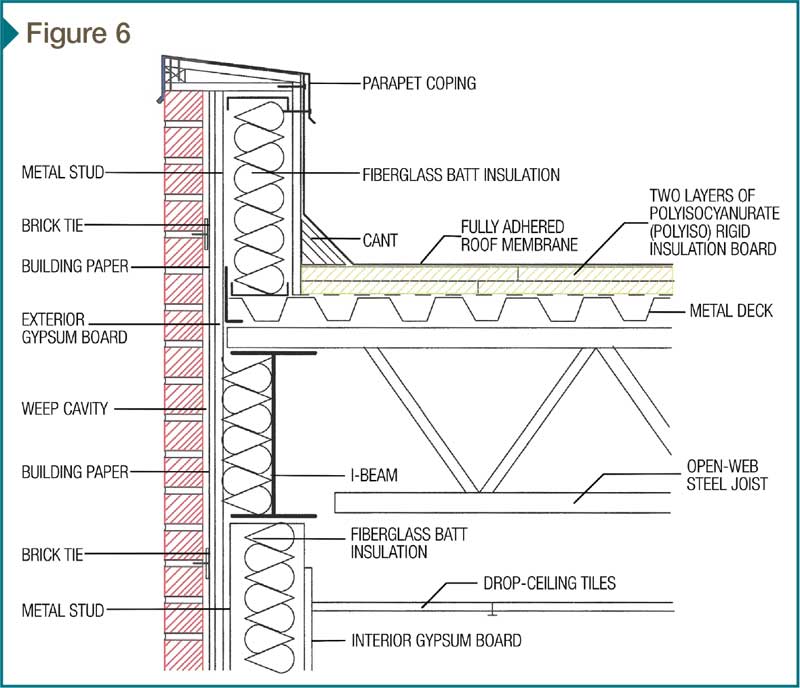

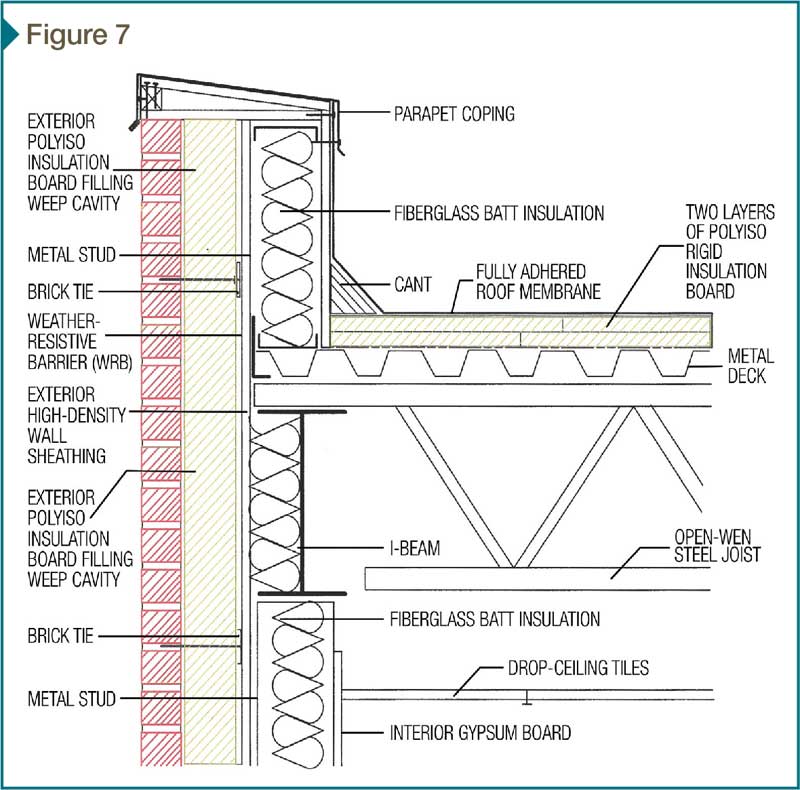

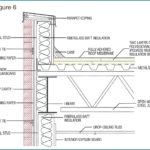

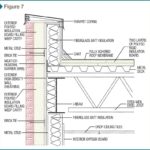

Figure 6 offers an illustration of an improperly insulated masonry wall—the result of having no continuous insulation installed on the exterior side of the interior wall and the interior side of the masonry brick wall. This area is often referred to as the weep cavity. Additionally, the building paper used to cover the exterior wall sheathing is not a suitable selection to serve as a WRB because there will be masonry brickwork wall extended over it. Once the building paper has deteriorated, the only way to properly replace the WRB would be to remove the brickwork—not a great option. Figure 7, on the other hand, is a prime example of a properly insulated masonry wall. The weep cavity has been filled with polyiso rigid insulation board, while the WRB is an appropriate product, designed specifically for this type of application and safe from deterioration.

A major problem in calculating IgCC R-values for insulation in framed wall assemblies involves the physical limitation of the cavity portion of the wall. Since the cavity depth is determined by the size of the standard framing members (typically 89- or 140-mm [3½- or 5½-in.] wood or metal studs), and because current minimum IECC standards for cavity insulation effectively reach the maximum possible value for the established cavity depth, the required IgCC increase in R-value typically must be applied only to the CI portion of the wall.

Therefore, a wall framed with 2×6 studs incorporates a 140-mm (5½-in.) cavity, typically insulated with R-20 glass fiber or similar material. As the IECC minimum R-value for a wood-framed 2×6 wall in Climate Zones 1 through 5 is R-20, the increase in R-value (or decrease in U-value) required by IgCC can only be applied to CI on the exterior side of the wall without increasing the width of the studs. In this case, the necessary additional R-value is approximately R-35, which can be achieved by installing a layer of continuous insulation board to the exterior side of the wall framing.

Finally, the calculation of IgCC R-values involves an additional confusing factor—the R-value tables in IECC are not derived as exact mathematical reciprocals of the corresponding U-value tables. Using the previous example of a roof with insulation above deck in Climate Zone 6, the IECC R-value table lists a value of R-30, which compares to an exact mathematical U-value reciprocal of U-0.033. However, the corresponding U-value table in IECC lists a value of U-0.032—slightly lower than the mathematical reciprocal. This difference can be attributed to assumptions regarding effective thermal values of other elements of the assembly (e.g. air films and framing members) that can increase or reduce overall U-value.

Another way to explain this is the IECC and ASHRAE U-value tables provide values for the complete assembly, while their R-value tables offer values for the insulation within the assembly. This means although a simple mathematical conversion of reducing IECC U-value by 10 percent will yield the correct IgCC U-value, a similar mathematical conversion of the new U-value to the new R-value will not.

Fortunately, this difference between U-value and R-value is addressed in Normative Appendix A of ASHRAE 90.1-2010, which provides adjusted equivalent insulation R-values for assembly U-values. Thus, the actual determination of insulation-value for IgCC requires an additional step of looking up the wall or roof assembly in ASHRAE Normative Appendix A, then extrapolating the required insulation R-value from the listing of equivalent R- and U-values in the appendix.

Again, drawing on the roof example in Figure 4, the mathematically calculated R-value reciprocal of the IgCC U-value is R-35.7. However, an interpolation from ASHRAE 90.1-2010 Normative Appendix A yields a slightly lower R-value of 35.5. In this case, the minor difference in R-value can be attributed to the air films that are located above and below the roof assembly.