Concrete Floors: Are ‘sealed’ and ‘polished’ synonymous?

Taking a closer look

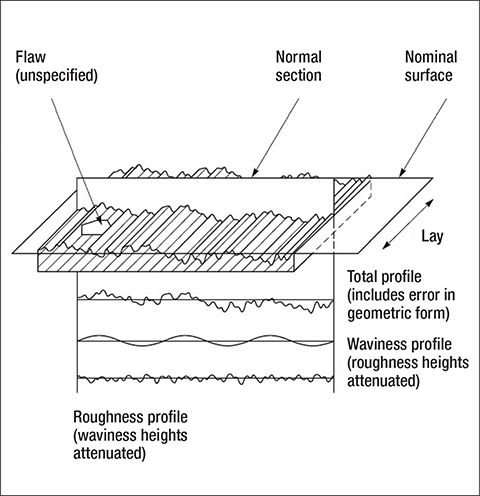

CSDA ST115 is concerned specifically with numerically quantifying the geometric, finely spaced irregularities of a concrete surface. It is not intended to address waviness, which is defined as the more widely spaced component of surface texture. Since profilometers measure both roughness and waviness, filters have been defined within the standard. These filters provide long- and short-wavelength cutoff values to eliminate data that does not significantly contribute to the roughness measurement.

Collecting this finely tuned range of data is possible because of the sensitivity of modern surface texture measuring profilometers. Their electronic recording systems capture minor fluctuations of stylus movement over the concrete’s evaluation length. ‘Ra,’ or average roughness, is the parameter used as the basis for CSDA ST115. The intent of the measurement method is to examine the ways in which finishing processes influence surface textures and how the surface texture, in turn, influences gloss, friction, and sustainability. The recommended profilometers can be used in conjunction with gloss meters and distinctness-of-image (DOI) meters.

The CSDA standard applies to any surface produced by processes of abrading, cutting, grinding, milling, honing, or polishing. It allows for the possibility of encountering high amounts of flaw, roll out, or voids and provides solutions for how to properly accommodate these flaws and get a reliable reading. The quantitative surface refinement number does not vary depending on the type of polish guard or sealer used.

Test results meeting the standard will indicate if steps in the polishing process have been skipped or are incomplete. They also enable the processor of a polished floor system to monitor the refinement capability of a specific tool in a multiple tooling system by measuring the surface of the concrete after each individual tool used. By knowing the quality of abrasives being currently used, a processer can then make an informed comparison to similar abrasives offered by competitive manufacturers. He or she can keep track of each step’s finish grade and potentially assemble the best tool selection procedure for the particular equipment or process.

Conclusion

CSDA ST115 is just the first step in moving the industry toward more systematic and responsible polishing practices. The standards committee assembled by the association also developed a companion document, a best practices guide known as CSDA BP-015, Green Polishing and Grinding Practices. This guide helps concrete polishing and grinding contractors perform their work in a more environmentally-responsible manner. Its recommendations cover work performed from office to jobsite. Additionally, a standard based on CSDA ST115 is likely to be adopted

by ASTM International. A draft of that document is currently in subcommittee review.

Implementing ST115 will result in a very detailed map of a concrete surface; it gives contractors, designers, and owners a more complete understanding of their finished product. Once a surface meets the requirements outlined in ST115, it will automatically produce a high gloss, since gloss is a by-product of surface refinement. The result will be improved operations and maintenance workflows, reduced costs, environmental benefits, and a better material in service for the project’s end users.

Andy Bowman is a surface metrology specialist and principal of Adaptive Concrete Innovations, LLC. He has served as chair of a committee comprised of 16 experts in the fields of surface metrology, concrete finishing, concrete repair, and concrete mix designs. This committee, which authored the ST115 Concrete Sawing and Drilling Association (CSDA) standard described in this article, represented five major industry associations and five continents. Bowman can be reached at bb@aciconcrete.net.