Concrete solutions to concrete rehabilitation

Air and water infiltration

Options to prevent air and water infiltration include:

- removing damaged areas and replacing with relatively non-porous patching material;

- ensuring proper drainage for concrete floor slabs to avoid pooling/ponding water;

- covering reinforcing steel with a minimum of 38 mm (1 ½ in.) of concrete, dense enough to limit chloride, water, and air migration; and

- applying a suitable penetrating concrete sealer to new concrete to limit the amount of moisture entering the member.

Any proposed sealers should be researched for applicability to the intended usage and environmental conditions, as well as regarding their compatibility with curing compounds.

Chloride contamination

Many concrete applications will experience the application of de-icing salts. However, there are several types available on the market. Sodium chloride has little or no effect on properly air-entrained concrete, but will corrode metal. A weak dose of calcium chloride has little effect on concrete, but strong calcium chloride solutions can be a different story. Effects of magnesium chloride vary, from slight deterioration to aggressive damage, especially in wet-dry and freeze-thaw conditions.

It is a good idea to try to reduce or eliminate chloride use near exposed concrete surfaces. One can employ less damaging alternatives to de-icing salts (e.g. calcium magnesium acetate). Other options include applying protective coatings to inhibit the intrusion of chlorides, air, and water.

Rehabilitation

Even if building owners have been less than diligent in the maintenance and upkeep of their concrete structures, all is not lost when defects and deterioration are discovered. Many products are available to rehabilitate a concrete structure suffering from virtually any combination of issues.

Penetrating concrete sealers

Penetrating sealers are chemicals applied to the concrete surface to protect against water infiltration. Due to their low viscosity, they are able to penetrate deep into hardened concrete to form a barrier, preventing liquid water from entering, but allowing water vapor to evaporate from the concrete. This can help reduce carbonation, freeze-thaw damage, and corrosion of embedded steel items. Typical sealers in this category include silanes and siloxanes or a combination of the two.

Epoxies

Numerous products fall under the ‘epoxy’ category; they can be used in a wide range of applications. Epoxies with low viscosity and a high modulus of elasticity can be either gravity-fed or injected into cracks to repair them. Crack movement and expansion should be monitored and proven to not exist prior to utilizing this repair. Using high-strength epoxy paste adhesives also provides a way to structurally bond to concrete.

A class of epoxies known as healer/sealers can be applied to the surface of a concrete slab to repair cracks and seal pores, protecting the concrete from water infiltration.

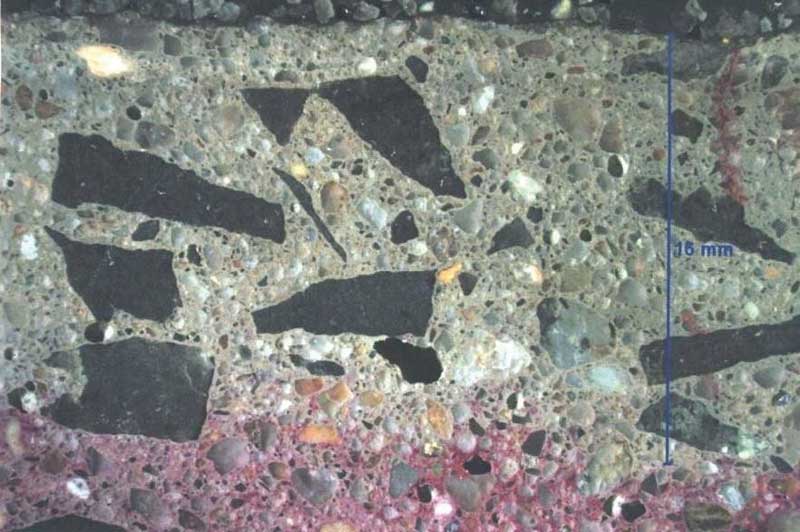

Patching mortars

When concrete is spalled or deteriorated and requires repair, many product solutions are available. Each has advantages and disadvantages based on the particular application in which it will be used.

The wide variety of patching mortars can be overwhelming. Some mortars are best used in vertical or overhead applications, while others are more suitable for underwater repairs. Some have integral migrating corrosion inhibitors to protect the existing rebar from further damage, while others have rapid curing capabilities to allow the structure to be put back into service more quickly. One must research each mortar for compatibility to application before usage.

Conclusion

Concrete is one of the world’s most popular construction materials. With proper installation procedures and regular maintenance, this versatile substance can last many years. If addressed in a proper and timely manner, many types of defects can be repaired and the concrete restored to like-new condition.

It is important to realize faulty concrete repair work can actually worsen structural problems or lead to further damage and even safety hazards. Therefore, when it is time to do repairs, building owners must consult a qualified concrete repair professional.

| BEST PRACTICES FOR CURING |

Proper curing procedures should be employed to ensure the concrete achieves its intended design strength and durability. Some methods of concrete curing include:

|

Steven J. Susca, PE, is senior engineer with Hoffmann Architects Inc., an architecture and engineering firm specializing in the rehabilitation of building exteriors. He develops engineering solutions for corrosion and other forms of reinforced concrete deterioration, both for existing parking structures and as preventive treatment for new construction. A member of the American Institute of Steel Construction (AISC), he earned his bachelor’s degree in civil engineering from the Universityof Connecticut. Susca can be reached via e-mail at s.susca@hoffarch.com.