Condensation: Why fenestration component selection matters

Condensation first occurring on the frame rather than the EOG indicates the CR rating cannot differentiate between the individualized performance of the glazing compared to the frame. In addition, the CR rating is not indicative of the threshold for which condensation begins, considering it was sudden and covered the whole frame even at a typical environmental condition of -7 C (20 F) exterior temperature and 50 percent interior RH, in comparison, the other system’s condensation gradually increased with each harsher environmental condition.

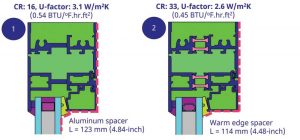

System 2 incorporated a small 13-mm (0.5-in.) thermal barrier and warm-edge spacer into the same frame as in system 1. These changes doubled the CR rating and improved the U-factor by 17 percent. Even though this system was improved and first experienced condensation at a higher humidity (50 percent RH), when condensation did occur, it still covered the full width of the frame (Figure 6). While condensation was reduced at the EOG because of the lower conductivity warm-edge spacer, condensation was dominated by the poorer thermal performance of the air-vented frame.

This also indicates that improved U-factor and CR do not directly indicate a relatively higher resistance to or lower amounts of condensation and that the performance of the individual components matters. A much higher condensation resistance would perhaps have been expected with a doubling of the CR value.

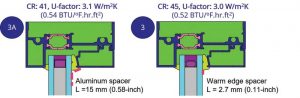

Systems 3A (aluminum spacer) and 3 (warm-edge spacer) had a higher performance frame; a larger thermal barrier at 25-mm (1-in.) and no

air-vent. The COG U-factor in these systems was downgraded by removing the low-e coating, compared to system 2. Note the U-factor for systems 3A and 1 are similar, yet their CR values are markedly different.

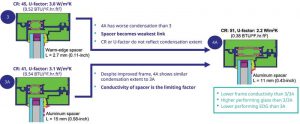

In systems 3A and 3, the spacer starts to become more influential in condensation performance, since the frame has a wider thermal barrier than system 2. For every environmental condition and fenestration system studied, replacing the aluminum spacer with a warm-edge spacer (system 3A versus 3), reduces the condensation extent (Figure 7). Condensation first occurred for system 3A at similar environmental conditions as system 2, but the extent doubled. This can be attributed to the improved frame, which was not affected by surface condensation.

In addition, system 3 has significantly improved condensation performance compared to system 3A. It only experienced condensation at the worst case of -29 C (-20 F) exterior temperature, 60 percent interior RH, and at lower temperatures in the other scenarios which could only be attributed to the introduction of a warm-edge spacer, all other things equal.

System 4A used a very wide thermal barrier and an aluminum spacer. This system had a higher CR rating (51) and lower U-factor (2.2 W/m2K, 0.38 BTU/F.hr.ft2) than system 3 (CR 45, U-factor = 3.0 W/m2K, 0.52 BTU/F.hr.sf) with the smaller thermal barrier and warm-edge spacer. Yet, there was a larger extent of condensation in the higher-rated 4A system under similar conditions compared to the system 3 (Figure 8). This reinforces the strong influence of the spacer conductivity on condensation. It also identifies a weakness in the rating systems which does not account for this influence in CR nor U-factor.