Selecting the right option

Sometimes, site restrictions dictate which of the systems to be used. For example, when piledriver vibration is undesirable adjacent to an existing hospital or a high water table is encountered, the primary foundation walls are often constructed by installing caissons of bored secant piles, diaphragm walls, slurry walls, or sheet piling. Alternate concrete piles are reinforced with steel H-shaped piles. This forms a 0.9- to 1.5-m (3- to 5-ft) thick wall that functions as the foundation wall.

With top-down construction, when the foundation is completed, the first floor slab is usually cast on either the grade at the ground level or the wall, which is braced with struts and walers as the earth is excavated, exposing the slurry wall. The slurry walls can then be scarified to produce a reasonably uniform surface or leveled off by casting a sand wall against it.

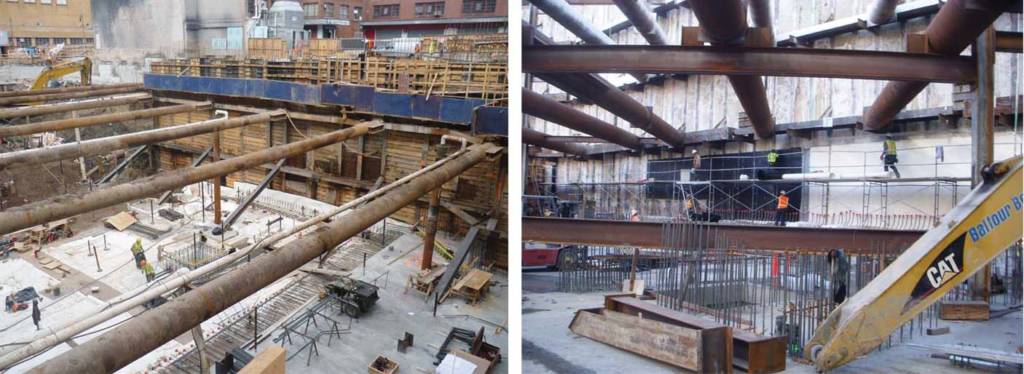

Where the site is fairly narrow and neither ties nor rakers are suitable, cross-lot blocking is the preferred system for bracing the soil-retaining system. Depending on the depth of the excavation, large pipes are installed to brace the walers at each floor or other practicable vertical spacing. Waterproofing is installed from the bottom up to each waler, and then the reinforced foundation is cast.

Pipes are relocated as required to enable the foundation wall to be constructed successively toward the top. They are removed as intermediate floor slabs replace them (Figure 10).

Basement walls

Basement walls (foundations) are designed to resist the lateral pressure of the soil and permanent or intermittent hydrostatic pressure, as well as support the exterior walls of the building above grade. They are generally constructed of reinforced concrete although in shallow basements they may be reinforced masonry.

Where positive side waterproofing is to be applied, the membrane should be covered with protection board or drainage composites and insulation. Drainage composites are unsuitable where the water table is above the footing. When there is a low water table and footing drains are provided, they may

be substituted for protection boards. Insulation is required where dictated by code. Where thermal resistance is required, insulation is generally extruded polystyrene (XPS), although oriented strand fiberglass could be used on shallow basements. Low-density (i.e. 1-pcf) expanded polystyrene (EPS) can be substituted for protection board. It is adhered to the membrane and becomes sacrificial when backfill settles and internally ruptures the boards.

Backfilling

The space between the foundation wall and the earth retention system should be backfilled with selected soil, sand, gravel, or low-density concrete.

Backfilling is one of the primary causes of membrane failure, with damage coming from large tree roots, boulders, construction materials, and similar refuse. Asphalt felt protection boards (ASTM D6506, Standard Specification for Asphalt Based Protection for Below-grade Waterproofing), generally 3.2 mm (1/8 in.) thick, offer sufficient protection, although they are no substitute for careful placement of selected backfill materials.

Sand is better in seismic areas, but generally more expensive than gravel. Backfill materials should be placed in 460- to 610-mm (18- to 24–in.) thick layers and compacted to 85 percent Modified Proctor. (The Proctor compaction test is a laboratory method of experimentally determining the optimal moisture content at which a given soil type will become most dense.) Lesser compaction will result in excessive settlement; greater than 88 percent will reduce the drainability. Where the SOE is in close proximity to the foundation walls and structural members project into the normal space to place and compact backfill materials, flowable fill is the preferred material.

Otherwise known as low-density cellular concrete fill, flowable fill is a lightweight concrete ranging from 20 to 60 pcf and 30 to 900 psi, but more often 16 pcf and 50 psi. It is pumped in place and can flow around obstructions. Its use should not substitute for the protection layer. Although it has some thermal resistance qualities, they are of little value when the flowable fill is saturated.

Flowable fill is sometimes used to pad SOE systems and rock-faced excavations to provide a surface on which to apply pre-applied membranes. In this use, it is often called a sand wall.

Where ground water is maintained well below the slab, footing drains and drainage composites or drainage backfills are required to relieve the pressure. The drainage composites and/or insulation generally provide sufficient protection for the post-applied waterproofing or dampproofing. However, where continuous hydrostatic pressure against the foundations exists, the drainage composite is unnecessary and the membrane requires protection only from the backfill.