Images courtesy Jensen Hughes

IBC Chapters 14 and 26

IBC 2018 requires exterior walls on buildings of Construction Types I-IV to comprise tested and evaluated assemblies. The specific requirements for assemblies or materials will be determined by Chapters 14 and 26. Within both sections of the code, fire testing of assemblies in accordance with NFPA 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, is required under certain conditions.

As a general rule, according to 2018 IBC, exterior walls of any height on buildings of Construction Types I-IV containing foam plastic insulation “shall be tested in accordance with and comply with the acceptance criteria of NFPA 285” (Section 2603.5.5). It should be noted NFPA 285 is an assembly and not a material test. Therefore, approval is dependent on all components of the exterior wall assembly.

Under Chapter 26 of 2018 IBC, other performance requirements for foam plastic insulation apply when products are used in certain exterior walls. For example, foam plastic insulation products must have a flame spread index of 25 or less, and a smoke-developed index of 450 or less (Class A as tested per ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials, or UL 723, Standard for Test for Surface Burning Characteristics of Building Materials). Industry professionals should be familiar with the complete requirements of Section 2603.5 of 2018 IBC when specifying and installing foam plastic insulation in exterior walls of commercial buildings.

Additionally, Chapter 14 includes requirements for exterior walls that are constructed with other combustible components such as metal composite materials (MCMs) and exterior insulation finish systems (EIFS). The general rule for the use of foam plastic insulation still applies when used with various exterior wall coverings—exterior walls of any height for Construction Types I-IV that contain foam plastic insulation must be tested and comply with NFPA 285.

Details on NFPA 285

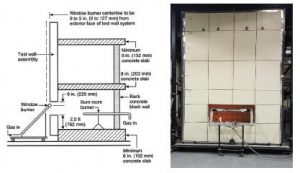

NFPA 285 provides a method for determining the flammability characteristics of exterior wall assemblies that are constructed with combustible components ranging from insulation and wall coverings to water-resistive barriers (WRBs). Developed from research initiated in the late 1970s and originally adopted as part of the Uniform Building Code (UBC) in 1988, NFPA 285 has been a keystone of building fire safety for many decades. The 2000 version of IBC was the first ICC-published code to incorporate NFPA 285, and the requirements have been expanded over subsequent versions to include additional assembly configurations.

| POLYISOCYANURATE INSULATION PERFORMANCE |

| Polyisocyanurate (ISO) insulation is a closed-cell, rigid foam board consisting of a foam core sandwiched between two facers. When used as a continuous insulation (ci) on exterior walls, ISO can function both as a high-R, energy-efficient insulation solution—creating a thermal barrier that reduces thermal bridges—and as an environmental barrier to protect the building from air and water intrusion. ISO is widely known for its high R-value per inch compared to other insulation options, and is installed on the exterior side of the building’s structure or frame and covered by an exterior finish. Many building professionals may be familiar with ISO’s reputation as an insulation material for commercial roofing that delivers excellent thermal and fire performance.

All construction materials, including ISO insulation, must provide a suitable margin of fire safety. ISO insulation possesses a high level of inherent fire resistance when compared to other foam plastic insulations due to its unique structure of strong isocyanurate chemical bonds. These bonds result in improved resistance to high temperature exposure as well as enhanced fire resistance. Additionally, ISO does not melt or drip when exposed to flame because it is a thermoset material. ISO forms a protective surface char when exposed to a sufficient flame, which resists the propagation of fire across the material (flame spread). This physical property is exhibited in the ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials, or “Steiner Tunnel” test where ISO insulation test specimens remain intact during the test’s fire exposure. Additionally, ISO can pass the National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, without exterior gypsum or added fire-stopping around the windows. ISO’s fire performance may offer other advantages and flexibility desired by design professionals. Building professionals should verify with the manufacturer the installation guidelines applicable to the specific material and assembly. |