Crystalline waterproofing and protection for concrete

How crystalline waterproofing works

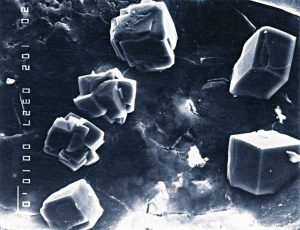

Crystalline waterproofing technology improves the waterproofing and durability of concrete by filling and plugging pores, capillaries, and micro-cracks with an insoluble, highly resistant crystalline formation. The process is based on two simple properties—one chemical and the other physical.

Concrete is chemical in nature. When a cement particle hydrates there is a reaction between water and the cement, which causes it to become a hard, solid mass, but there are also chemical byproducts given off that lay dormant in the concrete.

Crystalline waterproofing introduces a second set of chemicals. When these two groups are brought together (i.e. the byproducts of cement hydration and the crystalline chemicals) in the presence of moisture, a reaction takes place, resulting in the formation of an insoluble crystalline structure.

This crystalline structure can only occur where water is present, and thus, will form in the pores, capillary tracts, and shrinkage cracks in concrete. Wherever water can penetrate the concrete, the crystalline formation will follow.

When crystalline waterproofing is applied to the surface as a coating, a process called chemical diffusion takes place. The theory behind diffusion is a solution of high density migrates through a solution of lower density until the two equalize.

Water in the capillary tracts provides the solution of low chemical density. When crystalline waterproofing is applied to saturated concrete a solution of high chemical density is created at the surface, triggering the process of diffusion. The crystalline waterproofing chemicals must now migrate through the water (the solution of low density) until the two equalize.

The crystalline waterproofing chemicals now spread through the concrete and become available to the byproducts of cement hydration, allowing the chemical reaction to take place and the formation of a crystalline structure. As chemicals migrate through water, this crystalline growth will form behind an advancing front of chemicals. This reaction continues until the crystalline chemicals are either depleted or run out of water.

Chemical diffusion can take these chemicals about 300 mm (12 in.) into a completely saturated concrete substrate. Where concrete is not completely saturated, the crystalline chemistry only diffuses to the depth of water saturation. However, the crystalline structures still have the potential to travel deeper into the concrete in the future if water penetrates the material from the opposite direction, thus reactivating the crystalline chemistry.

Instead of just reducing the porosity of concrete, like water reducers, plasticizers, and super plasticizers, the crystalline formation engages the material filling and plugs the voids in concrete to become an integral and permanent part of the structure.

Since the crystalline formation occurs within the concrete it cannot be punctured or otherwise damaged like membranes or surface coatings. Crystalline technology also improves the durability of concrete structures, lowering their maintenance cost and extending their lifespan by protecting them against the effect of aggressive chemicals. Crystalline waterproofing is resistant to chemicals where the pH range is between three and 11 under constant contact and two to

12 under periodic contact.

Crystalline waterproofing tolerates temperatures between –32 C (–25 F) and 130 C (265 F) in a constant state. In the author’s experience, humidity, ultraviolet (UV) light, and oxygen levels also have no impact on the material’s ability to perform.

Crystalline waterproofing offers enhanced protection against the following agents and phenomena.

Carbonation

This is the result of the dissolution of carbon dioxide (CO2) in the concrete pore fluid, which reacts with calcium from calcium hydroxide and calcium silicate hydrate to form calcite (CaCO3). This process reduces the pH of concrete and its natural protection of reinforcing steel.

Alkali aggregate reactions

By denying water to these processes, crystalline waterproofing helps prevent these types of swelling reactions.

Chloride attack

Extensive chloride-ion diffusion testing shows concrete structures protected with a crystalline waterproofing treatment slows the diffusion of chlorides, thus extending the time-to-corrosion of the reinforcing steel.

Due to their limitations, membranes and coatings may leave concrete susceptible to water and chemical damage. The addition of crystalline technology can seal the pores and micro-cracks.

Matching the right crystalline technology with the application

Crystalline waterproofing and protection technology is sold in powder form and is mixed with water. It can be used in two ways:

- as a coating applied to the surface of existing or new concrete structures, such as foundation walls, floor slabs, or the inside of underground structures; and

- an admixture added directly into the concrete batch at the plant or truck for new construction, shotcrete, and precast applications.