Design without compromise: Balancing durable and energy-efficient buildings

Using moisture analysis to estimate long-term risks

The manner in which additional thermal insulation is added to framed wall assemblies for increased thermal performance is critical when it comes to durability. WUFI modeling can simulate different scenarios that may cause condensation and long-term durability risks for wall assemblies. Brief examples of WUFI analysis for estimating potential for winter or summer condensation, or drying rates following simulated wetting events, are described in this article. The wall assembly design and climate conditions (both interior and exterior) are specified for each example, and were selected as the best demonstration of a particular scenario.

The conclusions described for each example do not automatically extend to other conditions; however, the examples demonstrate how moisture analysis can be used for relative comparison between different design options to help select the lower risk options. John Straube, PhD, is among those who have published detailed studies on the use of WUFI moisture analysis for estimating the long-term durability risks of walls with high R-values. (For more information, see Research Report-0605, “Assessing the Durability Impacts of Energy-efficient Enclosure Upgrades Using Hygrothermal Modeling,” by John Straube and Christopher Schumacher. See also Research Report-0903, “Building America Special Research Project: High-R Walls Case Study Analysis,” by Straube and Jonathan Smegal. Finally, view Research Report 10-14, “High R-walls for the Pacific Northwest—A Hygrothermal Analysis of Various Exterior Wall Systems,” by Smegal and Straube.)

Due to inherent limitations of the WUFI model, simulation results represent relative performance of building assemblies, rather than quantitative predictions of the materials’ moisture content (MC). The trends in moisture accumulation and drying rates for different design options provide relative performance information.

Potential for winter condensation

Condensation during winter can be caused by moisture vapor diffusion or moisture transported by air leakage. During winter, diffusion or air exfiltration from interior space with higher water vapor concentration to outside spaces with lower concentration, could lead to condensation and increased moisture content within cooler exterior layers, such as exterior sheathing.

To control winter diffusion, a vapor barrier or retarder is installed on the inside of the wall in certain climates. WUFI analysis can compare the diffusion condensation potential for different wall assemblies and climate conditions by estimating the moisture content of the exterior sheathing. The questions most often asked regarding winter condensation is whether to use a vapor retarder (or what kind) to control diffusion wetting.

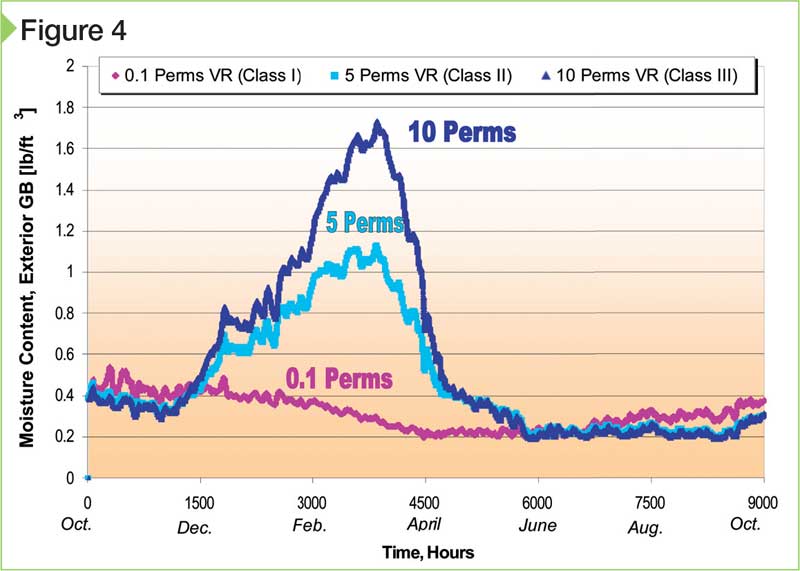

Figure 4 compares the moisture content in the exterior sheathing for three hybrid/split insulation walls with different vapor retarders that will meet the 2009/2012 International Building Code (IBC) requirements: 0.1 perms, 5 perms, and 10 perms (i.e. Classes I and III vapor retarders).

All other components for the three wall assemblies in Figure 4 are the same. They comprised:

- interior gypsum board;

- vapor retarder (as indicated for each case);

- 89-mm (3.5-in.) fiberglass batt insulation within the 2×4 steel stud cavity;

- exterior gypsum board;

- water-resistive barriers (WRBs) with >25 perms, over exterior sheathing; and

- 38-mm (1.5-in) extruded polystyrene (XPS) exterior insulation.

WUFI analysis was performed for the exterior climate of Chicago, Illinois (Zone 5A), and medium internal moisture conditions (50 percent ± 10 percent relative humidity [RH] and 21 C ± 1 C [69.8 F ± 1.8 F]).

Figure 4 shows the moisture content in the exterior sheathing increases as the vapor permeance of the retarder increases from 0.1 to 5 to 10 perms. However, the winter moisture levels in the exterior sheathing are relatively low and decrease to the equilibrium levels during the summer for all three cases. This indicates under these conditions, there is low risk of winter condensation and long-term durability issues due to vapor diffusion.

Another source of winter condensation, which is unfortunately not always recognized, is the exfiltration of warm, moisture-loaded interior air that can transport larger amounts of moisture than vapor diffusion. In fact, air leakage may be the main source of winter condensation. The excess moisture in the exfiltration air could be deposited on cooler exterior surfaces, such as exterior sheathing, leading to condensation.

The number of hours of potential condensation depends on interior moisture loads and exterior temperatures. Due to air leakage’s unpredictability, it is difficult to define failure criteria for its condensation potential. However, the condensation potential due to air exfiltration could be estimated by comparing the hourly temperature of the condensation layer (e.g. exterior sheathing) with the interior air’s hourly dewpoint temperature. When the temperature of the condensation layer is below the dewpoint of the interior air, condensation can occur if air exfiltration reaches the condensation plane. The lower the dewpoint temperature of the sheathing, and the longer sheathing temperature is below the interior air dewpoint, the higher the condensation potential.

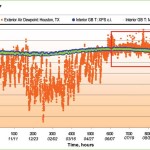

Figure 5 compares the air leakage condensation potential for traditional, split insulation and exterior insulation wall assemblies. For these simulations, Chicago’s exterior weather and medium internal moisture conditions (50 percent ± 10 percent RH and 21 C ± 1 C) were used. The number of hours of potential condensation for the year can be estimated for each case.

As exterior sheathing temperature for both traditional and split insulation walls is below the interior air dewpoint temperature during the winter months, there is potential for condensation from air leakage for both walls. This is highlighted by the red boxes in Figure 5. As expected, the exterior sheathing temperature for the split insulation wall is higher with fewer hours of potential condensation as compared to traditional wall design. However, there is no potential for condensation from air leakage in the exterior insulation wall, since the actual temperature of the sheathing is always above the interior air dewpoint.

Potential for summer condensation

During the summer, condensation can be caused by vapor diffusion or moisture transported by air leakage. The main concern is diffusion or air infiltration from warmer, more humid exterior environments into cooler interior layers. The summer diffusion condensation potential can be estimated by analyzing moisture content of cooler interior layers, such as interior sheathing.

The often-discussed inward solar-driven moisture diffusion can be simulated for a moisture storage cladding, such as brick or stucco. The air leakage condensation potential can be estimated by comparing the actual temperature in the potential condensation layer (interior sheathing) with the exterior air dewpoint temperature.