Designing balcony railings for windy vibrations

by Catherine Howlett | April 1, 2013 10:47 am

[1]

[1]by Mahmod Samman, PhD, PE, FASME

Balcony railings come in different shapes, materials, and styles. When railings are installed in high-wind areas, design teams must verify the adequacy of their dynamic characteristics in order to ensure occupant safety and comfort.

One of the most common railing designs is an aluminum frame with vertical pickets (Figure 1). The popularity of this material is attributed to a combination of factors such as:

- aesthetics;

- view;

- strength;

- durability;

- lightness;

- rust-resistance; and

- relatively low material and installation costs.

From a structural standpoint, balcony railings are primarily designed to withstand mechanical loads imposed by occupants. Since this design criterion can be easily met using a metal like aluminum, the need to produce less-expensive options resulted in products designed to minimize weight.

In many applications, new lighter-weight aluminum railings still work because they satisfy structural requirements and applicable safety standards. However, in high-rise buildings, especially in coastal areas, these products can suffer from a serious, previously unknown, functional failure. The lighter structural members can become flexible enough to experience resonance under wind excitations. When this happens, the resulting noise and vibrations can make these costal properties virtually uninhabitable. Additionally, the dynamics of resonance can cause fatigue damage in these structural members that can lead to structural failure of connecting welds.

[2]

[2]Images courtesy Mahmod Samman

Structural considerations

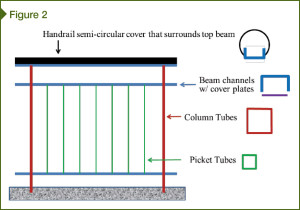

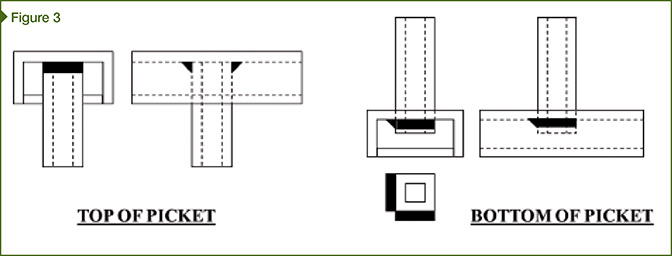

As shown in Figure 2, aluminum balcony railings are usually composed of vertical columns anchored to the floor, two or three horizontal beams running between the columns, and vertical pickets between the beams. These members are usually joined using welded connections (Figure 3).

Like all structures, the response of balcony railings to dynamic excitation is defined by natural frequencies and mode shapes. Natural frequencies (i.e. number of oscillations per second) are dynamic weak spots at which structures lose most of their strength. If a structure is excited at any of these frequencies, it vibrates excessively. The mode shape associated with each frequency is the shape of oscillation the structure exhibits. Lower frequencies are easier to excite because they require less energy. The lowest frequency is usually referred to as the ‘fundamental frequency’ because it is the easiest and most likely to excite and observe in everyday structures.

The frequencies and mode shapes of any structure are a function of mass, stiffness, and to a lesser degree, damping. Natural frequencies increase as mass decreases and stiffness increases. If increasing the stiffness is accomplished by adding mass, the net impact cannot be predicted without an engineering analysis. In most cases, however, proper stiffening of structures causes a net increase in natural frequencies, making the structure more difficult to excite into resonance.

[3]

[3]The dynamics of balcony railings

The stiffness of aluminum balcony railings is a function of several factors, including:

- material strength;

- cross-sections;

- span lengths; and

- the type of connections joining the structural members.

The effort to lower the cost of aluminum railings resulted in designs consisting of longer members, smaller cross-sections, thinner walls, and weaker-welded connections—all of which make these railings more flexible and susceptible to dynamic resonance at lower natural frequencies.

When railings are exposed to high-speed winds in high-rise buildings and coastal areas, air flow can produce sufficient dynamic excitation to set these railings into resonance. The mechanism producing this dynamic excitation is vortex shedding.

[4]

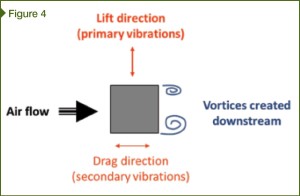

[4]Vortex shedding is the unsteady oscillating fluid flow that occurs when the flow of a fluid (i.e. air or water) is disrupted by an elongated object. For this phenomenon to occur, fluid needs to flow at a certain velocity range that depends on the size and shape of the disrupting object. Due to this unsteady flow, vortices are created at both sides of the back of the object with the stronger vortex alternating from side to side.

[5]

[5]As shown in Figure 4, when air flows across a structural member, it creates vortices on both sides downstream of the member. The difference in pressure from the consequent uneven pressure drops on the sides of the member, causing it to move side to side perpendicular to the air flow’s direction. Movement in wind direction (i.e. drag direction) is of secondary significance. Primary structural oscillations perpendicular to air flow, or in the lift direction, is referred to as vortex-induced vibration (VIV).

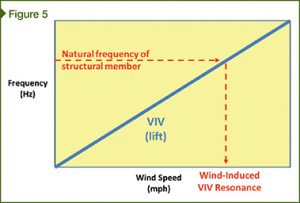

The relationship between wind speed and VIV frequency depends on several factors relating to the properties of flowing air and the structural member’s surface and shape. For simplicity, this relationship can be expressed using the blue line in Figure 5. As the graph indicates, higher wind speeds result in higher excitation frequencies. Since resonance occurs when excitation frequency matches the structure’s natural frequency, any structural member can potentially be excited into resonance under high enough wind speeds.

Structures such as marine risers, bridges, and long utility poles/towers are routinely designed to resist VIV. When the length of a structure or a structural member is too long compared to its cross-sectional depth, it becomes more susceptible to damage by VIV. (The most recognized example of this phenomenon is the famous 1940 collapse of the Tacoma Narrows Bridge in Washington.) Fortunately, wind speeds required to excite everyday structures are normally higher than the typical range in habitable areas of the world.

[6]

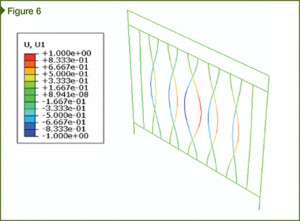

[6]Figure 6 shows the mode shape of lateral picket vibrations of a balcony railing as simulated using finite element analysis. This vibration pattern has been verified in wind tunnel tests and observed by occupants at wind speeds and gusts as low as 32 to 40 km/h (20 to 25 mph). This example of railing resonance can generate severe magnitudes of noise and vibrations in windy days described by some occupants who experienced this phenomenon. In a study conducted by this author, the occupants described the noise and vibrations as “train noise,” “floor vibrations that rattle furniture,” and “uninhabitable.” In addition to noise and discomfort, when these vibrations take place for long periods, fatigue damage at connecting welds may cause some pickets to break off, exposing occupants to physical danger.

Recommendations

While wind excitation is not currently a design factor for balcony railings, recent industry trends and occupants’ experience suggest it should be. Some developers of recent high-end coastal properties in several southern states have learned this lesson in an unpleasant way. Complaints from occupants have caused expensive retrofits and disputes. In some instances, legal actions were pursued to settle the matter. This problem has become so common, several companies have been formed to develop and sell repair kits and services to property owners to control these vibrations.

In the absence of industry standards, there are no adequate means for developers, architects, or railing manufacturers to handle this problem or predict railings’ performance. In extreme cases, all parties can also become targets for legal action. To ensure the safety and comfort of occupants, and to protect the interests of all parties involved, some corrective action must be taken.

[7]

[7]Typically, problems of this sort can be handled using one, or a combination of, the following:

- engineering analysis and/or testing requested by the architect on a project-by-project basis;

- engineering analysis and/or testing conducted by manufacturers during product development; and

- industry-wide standards or design tools.

Due to the magnitude of the problem and potentially prohibitive cost of the first two options for small projects or manufacturers, the third option seems to be the most effective solution.

An industry-wide mechanism may be accomplished using various forms. One option is a rating system based on physical wind-tunnel testing of product specimens. This is the most accurate way to determine the wind speed at which railings become susceptible to resonance. The system can capture the actual behavior of imperfect structural connections and variations in the manufacturing process, which are difficult to handle using computer models. The generic system can be used for any design or configuration. If well-designed laboratory instrumentation and procedures are developed, this approach can produce results in a timely and cost-effective manner.

Another option involves using design aids based on simplified analysis of common railing configurations. Such tools, which may be in the form of design charts or software, can be used by manufacturers to design products and by architects to estimate the resonance wind speed of available products. This approach typically requires:

- determining design parameters;

- developing an analysis methodology;

- executing computer simulations; and

- calibrating accuracy using representative wind-tunnel testing.

To encapsulate many design parameters into a simplified office tool, a sizeable upfront investment of resources may be necessary.

Conclusion

An effective long-lasting solution to vortex-induced vibrations of balcony railings requires group action by architects, manufacturers, or both. Given the observed trend, esecially in coastal regions, and potentially serious consequences of this problem, there seems to be enough incentive for both parties to support such an endeavor.

Mahmod Samman, PhD, PE, FASME, is the president of Houston Engineering Solutions. He has more than 25 years of engineering experience. Samman earned his PhD in engineering mechanics from Duke University in 1991 and is a licensed professional engineer in Texas. In addition to his consulting practice, he taught a graduate level course in finite element analysis at the University of Houston, as well as numerous seminars to industry professionals. Samman has one patent, over 30 journal and conference publications, and numerous industry reports. He is a Fellow of the American Society of Mechanical Engineers (ASME), and a member of the American Society of Civil Engineers (ASCE). He received the Herbert Allen Award from the South Texas Section of ASME, a Fulbright Scholarship from the U.S. Department of State, and the Young Engineer of the Year Award from the City of Houston. He can be reached at mms@hes.us.com.

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/04/bigstock_5433061.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure4.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure5.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/balcony_figure6.jpg

Source URL: https://www.constructionspecifier.com/designing-balcony-railings-for-windy-vibrations/