by Sean Gerolimatos

The way we build bathrooms is changing. Owners of homes, condominiums, hotels, and spas want more than just utility—they are seeking a retreat-like atmosphere with the latest design elements, while still requiring reliability and durability. At the same time, many want their bathrooms to be barrier-free.

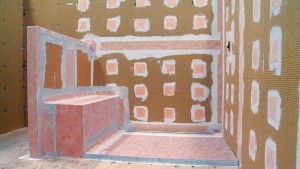

These latest bathroom designs include curb-free showers, along with large-format tiles extending from the floor into the shower, and custom building elements like shower seats and vanities. Offering design flexibility and enduring performance, these applications continue to grow in popularity for various reasons.

For some, limited mobility due to disability or age makes barrier-free showers a necessity for access. Other owners simply want to plan for the future, ensuring they have an accessible bathroom that allows them to age in their home with security and independence. According to a report from the Federal Interagency Forum on Aging-related Statistics, the number of Americans over the age of 65 will increase from 40 million in 2010 (13 percent of the population) to an estimated 72 million in 2030 (20 percent of the population)—this represents an 82 percent increase in total and a 47 percent increase in share.

The coming population shift has brought more focus on the building needs of the elderly and opportunities for building professionals in the market. For example, the National Association of Home Builders (NAHB) offers the Certified Aging-In-Place Specialist (CAPS) program to educate and certify building professionals in this area.

Moisture management

Ceramic tile coverings are not inherently waterproof—therefore, waterproofing is required behind the tiles to protect the substrate.3 However, this is only one component in an effective moisture management system. Moisture management is a systematic method to contain water in both liquid and vapor form and enable it to pass through an assembly efficiently using materials not adversely affected by moisture.

Traditional tiled showers use what can be described as a ‘water-in/water-out’ system wherein an unbonded pan liner is laid on a slope on the floor and clamped to the drain. Material options for the pan liner include:

- polyvinyl chloride (PVC) meeting ASTM D4551, Standard Specification for PVC Plastic Flexible Concealed Water-containment Membrane; or

- chlorinated polyethylene (CPE) meeting ASTM D4068, Standard Specification for CPE Sheeting for Concealed Water-containment Membrane.

A vapor retarder, such as polyethylene or tar paper, is applied to the walls and lapped over the pan liner. A mortar bed must be placed over the pan liner to provide support and a bonding surface for the tiles. Mortar may be floated on the walls to perform a similar function, but many tile-setters are not trained in floating mortar and instead use a tile backerboard, such as a cementitious backer unit.

As the shower is used, liquid water passes through the tile covering and seeps through the mortar base to the weep holes in the drain. Similarly, water vapor passes through the tile covering, condensing on the vapor retarder, and ultimately passing through the shower base assembly. When properly constructed, these showers can provide good performance and service life. However, common mistakes can lead to problems. For example, if no pre-slope is provided under the pan liner, water can collect in the mortar base and become a haven for mold growth. Or, if no vapor retarder is provided on the walls, moisture can enter the wall cavity and damage moisture-sensitive materials such as framing members, wall board opposite the wall cavity, and wood subfloors.

The modern approach to moisture management in tiled showers produces a ‘sealed’ enclosure. This approach employs bonded waterproofing membranes meeting the requirements of American National Standards Institute (ANSI) A118.10, American National Standard Specifications for Load Bearing, Bonded, Waterproof Membranes for Thin-set Ceramic Tile and Dimension Stone Installation, which are applied atop the shower base and walls, and connected to the drain at the top of the assembly via an integrated bonding flange.

As the shower is used, liquid water passes through the tile covering, but is contained just under the surface by the membrane. The resulting assembly provides superior moisture management as it does not permit moisture to penetrate into the mortar bed or solid backing, allowing the assembly to completely dry between uses and reducing the potential for efflorescence and mold growth within the system.