A matrix of NFRC-recognized sizes can allow extrapolation beyond NFRC fixed sizes. This is an especially good tool for sizing comfort heating and cooling systems. The matrix can be created using the same COG increments to obtain various system U-factors.

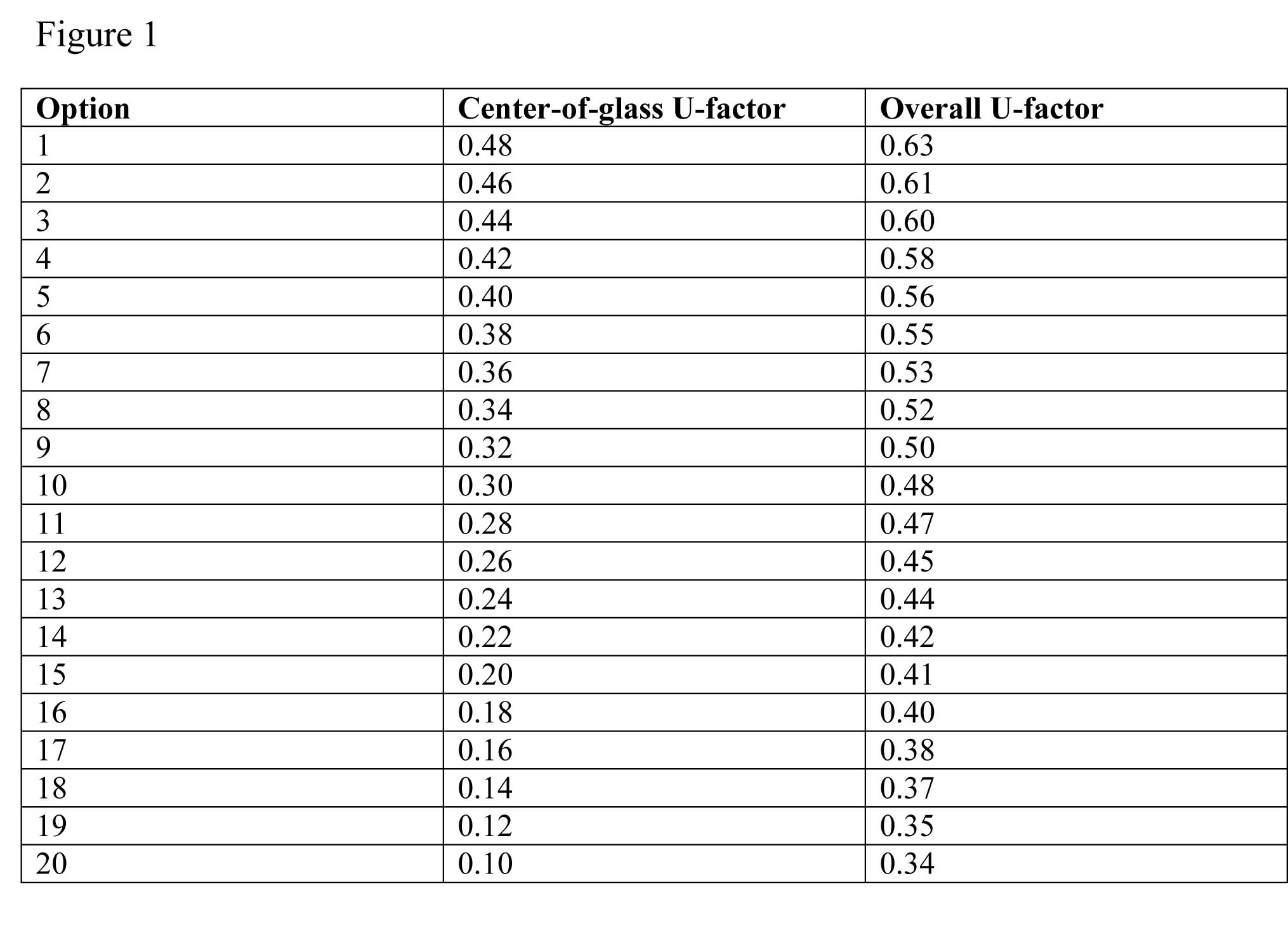

This matrix is generated by an NFRC-accredited simulation laboratory, or by an NFRC independent approved calculation entity utilizing approved frame, glass, and spacer components within the NFRC Component Modeling Approach Software Tool (CMAST) program. The matrix can be used to prepare a ‘fenestration product rating certificate’ for a specific project—an example is shown in Figure 1.

Spandrel area U-factor

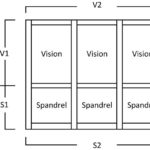

Spandrel areas, defined as those parts of an opaque wall between the heads of windows and the sills of the windows above them, are handled in essentially the same manner as vision areas. A graph is constructed giving the thermal performance for this specific framing system with variations in the spandrel insulation and in the percentage of spandrel. This is accomplished by simulating the edge and center of the spandrel with insulation.

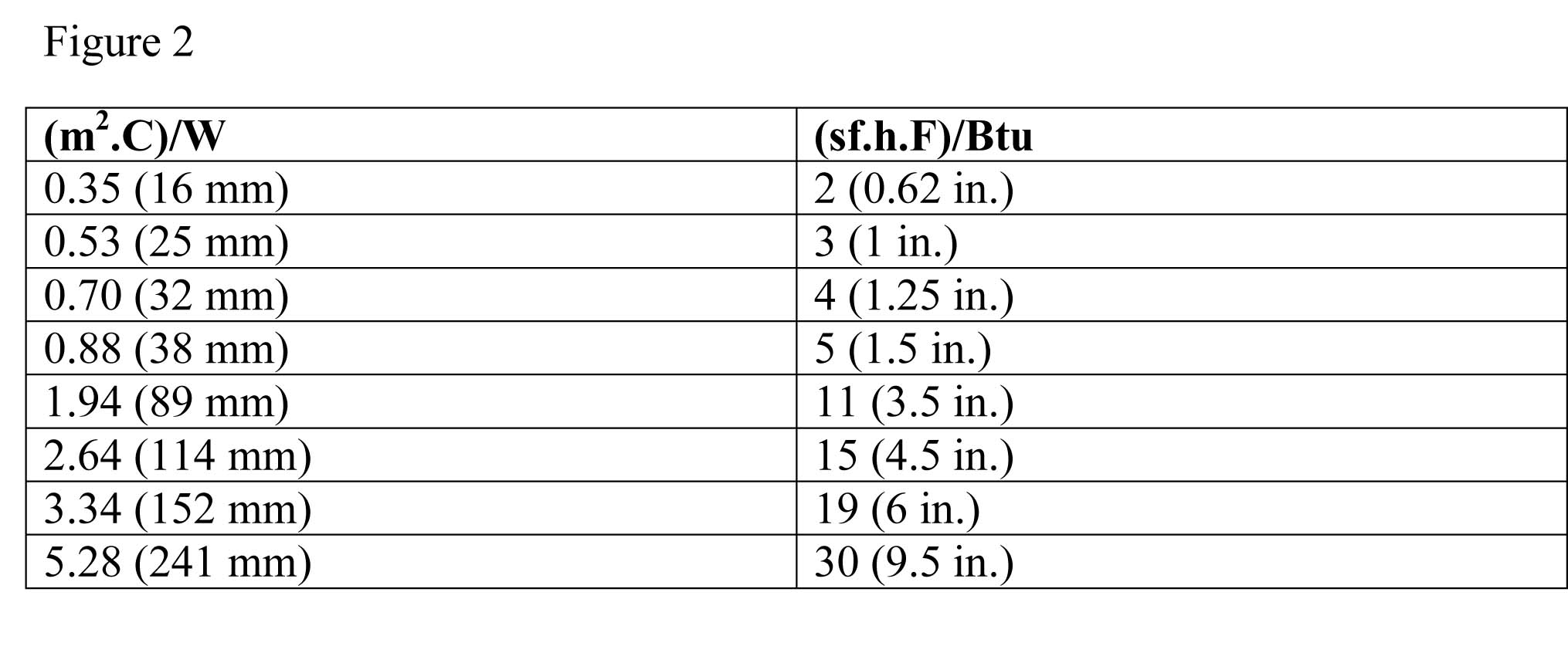

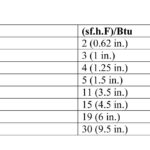

It is assumed the spandrel insulation does not cover the framing members, is flush with the 6-mm (0.25-in) glass, and has a foil facing exposed to the interior. At a minimum, the spandrel insulation shall be based on the R-values and thicknesses (in parentheses) in Figure 2.

Solar heat gain coefficient

A system-specific SHGC is developed in much the same manner as the U-factor, but determined in accordance with NFRC 200, Procedure for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance at Normal Incidence.

For a given glass type, the relationship between SHGC and percent of vision area is linear. A graph is constructed utilizing COG SHGC determined in accordance with NFRC 200 and ranging from 0.05 to 0.75 in 0.05 increments. The SHGC for each glazing option is determined at 70 and 95 percent vision area utilizing the same infill aspect ratio as in the test unit.

Visual transmittance

System-specific VT values can be developed using the same approach as for determining SHGC, again, in accordance with NFRC 200.

Building-specific thermal performance

An estimate of the overall U-factors for a specific building is determined by the area-weighted U-factor from each component. This is accomplished for the vision area, spandrel area, and/or combined vision/spandrel area by depicting actual U-factors in a chart format developed from the following generalized area-weighted equation.

UO= (UCOGACOG + UEOGAEOG + UFAF)/APF

Where:

UO = U-factor (overall);

UCOG = U-factor (center-of-glass);

ACOG = Area (center-of-glass);

UEOG = U-factor (edge-of-glass);

AEOG = Area (edge-of-glass);

UF = U-factor (frame);

AF = Area (frame); and

APF = Total area (area of the rough opening in the building envelope for the fenestration product, less installation clearances).

Vision area

To determine the U-factor for the vision area of a specific building, it is first necessary to know the COG U-factor and the percent of vision area to total area. One enters the chart on the horizontal axis at the appropriate percentage of vision area to total area, and projects a line vertically until it intersects with the COG U-factor line for the building. Then, a line is projected horizontally until it intersects with the vertical axis. This intersection indicates the system U-factor for the vision area. Since the relationships are linear, interpolation or extrapolation is permitted within the chart. COG U-factor typically is given in the glass manufacturer’s data as wintertime (night) U-factor.

Spandrel area

To determine the U-factor for the spandrel area of a specific building, it is first necessary to know the R-value of the spandrel insulation and the percent of spandrel area to total area. The system U-factor is determined in the same manner as that for the vision area.

Combined vision and spandrel

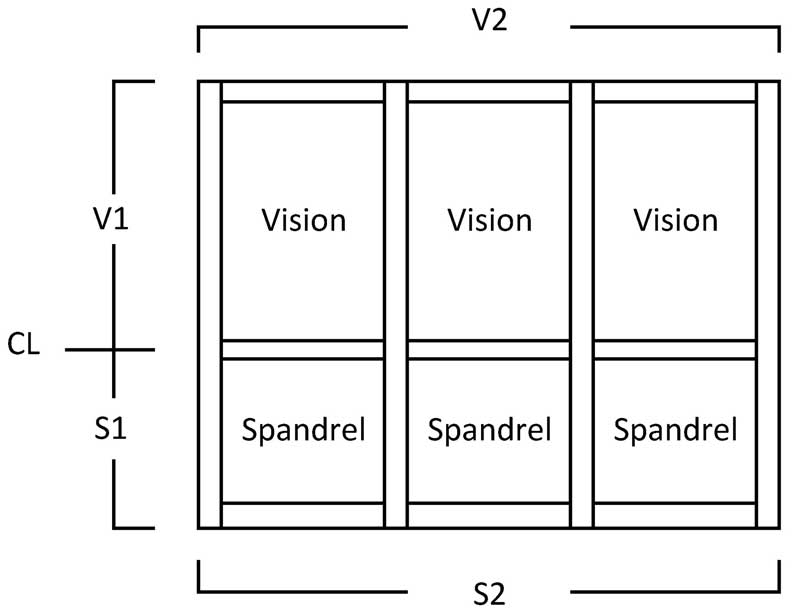

For fenestration systems that have a combination of vision and spandrel areas in a single elevation, such as in a curtain wall, the vision and spandrel portions must be separately determined. If a single U-factor is required for an elevation that contains both vision and spandrel, it shall be determined by area weighting the respective U-factors to the total area of the entire assembly (Figure 3). The SHGC and VT for a specific building are developed similarly based on COG values.

Representative values for generic products

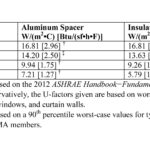

While product- and project-specific U-factors will vary and are determined in accordance with the method just described, framing systems in commercial building applications typically consist of aluminum structural members that can be categorized generically as non-thermal, thermally improved, containing a thermal barrier, structurally glazed, or a combination thereof. These are defined as follows:

- Non-thermal framing: System members with less than 1.6 mm (0.062 in.) separation between interior and exterior surfaces.

- Thermally improved framing: System members with a separation greater than or equal to 1.6 mm (0.062 in.), but less than 5.3 mm (0.210 in.), provided by a low-conductance material where thermal conductivity is less than or equal to 0.5 W/mK (3.6 Btu in/h·sf·F), or open air space between interior and exterior surfaces. Examples of such systems include members with exposed interior and/or exterior trim attached with low conductance clips or skipped-debridged systems, which employ intermittent (instead of continuous) machined slots in the conductive material to reduce heat flow and are categorized as non-thermal framing systems in this standard practice.

- Thermal barrier framing: System members that have a minimum of 5.3-mm (0.21-in.) separation provided by a low-conductance material where thermal conductivity is less than or equal to 0.5 W/mK (3.6 Btu·in/h·sf·F), or open air space between the interior and exterior surfaces. Examples of such systems include poured and de-bridged urethane systems, crimped-in-place polymer isolator systems, and pressure-glazed systems with intermittent fasteners.

- Structurally glazed framing: A method of glazing where frame members are not exposed to the exterior.

The generic thermal transmittances of the four framing systems are pre-calculated as shown in Figure 4. These pre-calculated U-factors are conservative and may be used as an estimating tool in the early phases of design. AAMA 507 shows graphs for all these systems.

AAMA 507 uses the same test and computer simulation tools required by NFRC and results in similar values for U-factor and SHGC. The main difference is the AAMA procedure combines frame and glass ratings to provide an overall system rating without requiring additional project-specific simulations and laboratory fees. It can also be used to calculate the performance of actual products with real vision and spandrel area, rather than that of a hypothetical model size as in the NFRC procedure—an approach that produces less-accurate estimates of actual demands and HVAC-sizing the more the real product varies from the model size.

As the Aluminum Extruders Council (AEC) has observed: “AAMA 507 is a simple, usable and enforceable option for rating commercial windows, and is well-suited to the process used to construct commercial fenestration.”