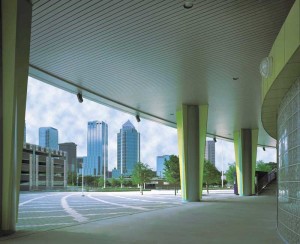

‘Green’ design and colorful finishes

The exterior metal soffits’ composition not only offers enduring performance and aesthetics, it also offers sustainable design attributes. According to the Aluminum Association (AA), the material is infinitely recyclable with 75 percent of all aluminum ever smelted still in use. Metal ceiling systems can approach 100 percent recycled material content and are 100 percent recyclable at the end of their usefulness as an exterior soffit. Additionally, it is currently estimated that more than 90 percent of aluminum used in buildings is recycled after service, making it one of the most recycled building materials in the world.

Further supporting green goals, the aluminum panels may be finished with baked enamels, anodize or powder-coated paint containing no VOCs. Functional, painted coatings in standard black, white, and silver colors remain the most popular choices, but a broad palette of hues and patterns are available for bold designs. Solid, painted finishes span the spectrum of amethyst to emerald, or true blue to cardinal red. Patterned, painted finishes include those mimicking wood grain or metal. Anodize finishes emphasize a sleek, metallic appearance in silver to copper tones and in reflective chrome or brass.

Care and cleaning

Throughout the building’s life, the finished metal soffits require minimal maintenance to retain the intended look and performance. Some soiling or smudging of a component’s finish is bound to happen. To ensure they are cleaned appropriately, manufacturer’s instructions should be followed. Recommendations may include:

- A mild, non-abrasive cleaning agent is typically used for cleaning painted or reflective surfaces. Abrasive cleaning agents should not be employed

as they may scratch, mar, alter, discolor, and/or remove the finish. - Before cleaning the finish, a trial test should be performed on a section that will be hidden from view once installed. This ensures the cleaning agent selected is appropriate and will not damage the finish.

- Once an appropriate cleaning solution has been selected, care should be taken to only use the necessary amount. Ceiling components should not be soaked in the solution.

- A clean, soft sponge or cloth should apply the cleaning agent to ensure the applicator does not contain any abrasive elements that may damage the finish in question.

- Any excess cleaning solution should be removed immediately so it does not dry and leave a residue. In the event a large area needs to be cleaned, it is advisable to break the area down into smaller, more manageable sections so time is available to complete each cleaning cycle phase.

- After cleaning the soiled or smudged area, the surface should be wiped with a dry, soft cloth to remove any residual cleaning solution and dry the area. A damp cloth should be used to remove any residue left behind by a dry cloth.

- After the components are clean, a few minutes should be dedicated to air drying before installation. The clean components must be dry because other ceiling materials, such as ceiling board or insulation that come into contact with the cleaned components, can be susceptible to damage from moisture.

Conclusion

Since each building and its environment are unique, special attention must be given to designing an

exterior soffit. Codes, budgets, and longevity all must be taken into account, along with the design intent. With proper installation and maintenance, a metal ceiling soffit will perform as planned for many years—protecting the building itself from water and pest damage, and also providing safety for occupants and owners.

Edward Williams is a manager for Chicago Metallic Corporation’s metal ceilings unit. He has more than 30 years of experience in manufacturing ceiling systems for commercial spaces, partnering with owners, designers, and installing contractors. Williams is an affiliate of the International Interior Design Association (IIDA). He can be contacted via e-mail at williamse@chicagometallic.com.