Designing metal ceilings for exterior soffits

by Catherine Howlett | January 6, 2013 2:25 pm

[1]

[1]by Edward Williams

Exterior soffits perform essential functions for ventilating, shading, and directing water away from a building. Regardless of geography or climate, exterior soffits are subjected to positive and negative wind loads. to protect occupants and their surroundings from damage, building codes have revised provisions for wind speeds and risk categories.

Metal ceiling systems can meet the performance challenges of exterior soffits, as well as support buildings’ aesthetic and sustainability goals. Constructed mostly of aluminum, these assemblies are durable and do not deteriorate or deform. Conventional materials in exterior soffits include:

- gypsum board and plaster;

- wood and plywood;

- vinyl; and

- exterior insulation and finish systems (EIFS).

Aluminum’s durability has been proven in daily use and extreme conditions, from the Arctic to Gulf Coast. As it has the strength of steel at a third to half the weight, it lightens a structures’ ‘dead load’ and makes shipping, handling, and installation easier.

Aluminum’s physical properties allow metal ceiling panels to be formed into squares, linear planks, and other geometric shapes. Available in various styles, thicknesses, and finishes, the panels convey a unified appearance in both interior and exterior applications.

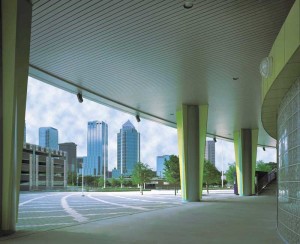

Metal panels may be installed as flat ceilings that carry the intended design from a building’s interior lobby through to exterior soffits. This softens the transition from interior and exterior environments and presents a clean, unbroken look. Many designers appreciate this visual continuity, particularly in highly transparent buildings with large glass openings. For grand, curving entrances, the metal panels can be either field-fabricated at the jobsite or specified with factory-fabricated radius systems to create barrel-vaulted canopies.

[2]

[2]Proper installation, enduring performance

As a factory-fabricated system, exterior metal ceiling components are pre-engineered, pre-finished, and ready for installation. These systems do not require extra labor, time, or materials to frame, sheet, or paint the soffit onsite. There is no need to second-guess how the ceiling ties to the structure above it when the responsibility for engineering is defined in the specification. The ceiling can be engineered, fabricated, and verified to meet the performance requirements and simplify installation—from the spacing of supports to the screw placement.

Metal ceiling systems accommodate lighting, air-diffusers, audio accessories, and structural items that must pass through the soffit assembly. Once installed, the plenum remains accessible for future care and cleaning. With proper closures, exterior metal soffits are inhospitable environments for pests compared to organic materials which can attract ants, termites, wasps, and other insects. Aluminum is impermeable to air, water, light, and microorganisms. Metal ceiling systems neither accumulate moisture nor contain volatile organic compounds (VOCs) or substances supporting mold or microbial growth.

[3]

[3]Metal ceiling systems can easily accommodate ventilation measures for cooling the plenum and subsequently the roof systems—the panels can be perforated or vents can be installed in them. In the case of linear systems, perforations can be used and/or the spaces between panels can be left open for ventilation.

Made of non-combustible material, exterior metal soffit systems are typically Class A fire-rated and rarely included in Underwriters Laboratories (UL) time-rated designs. While aluminum is inherently corrosion resistant, care should be taken when specifying materials and finishes in coastal areas. A metallurgist and manufacturer should be consulted before using these systems in warm, humid environments where salt spray occurs. Also, in areas where there are wide temperature swings, specifiers must consider thermal expansion in their design.

Different metals and materials expand and contract at different rates. For example, the linear expansion co-efficient of the International Alloy Designation System’s 3000 series aluminum is approximately 23.4 x 10-6 cm/cm – C (13.0 x 10-6in./in.- F). This equates to about a 5 mm (0.2 in.) change in length in a 15.2-m (50-ft) run of metal when there is a temperature change of 4 C (25 F).

Codes and criteria

Regardless of size, location, or occupancy, exterior metal soffits should meet necessary building codes and criteria. The 2012 International Building Code (IBC) and 2010 Florida Building Code (FBC) are two recent examples where wind load design requirements and related descriptions have been updated. These revisions are largely due to the 2010 edition of American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7, Minimum Design Loads for Buildings and Other Structures.

In particular, ASCE/SEI 7-10 revised the methodology and terminology used for establishing basic wind speed. These revisions include:

- Strength Design (SD), or ultimate, wind speeds replacing the former use of Allowable Stress Design (ASD) wind speeds (three difference wind speed maps[4] are provided);

- deletion of Importance Factors, previously used to determine basic design wind speed;

- switching of Exposure Category for hurricane-prone regions from Exposure C to D (2012 IBC also notes an exception for Office of Statewide Health Planning and Development [OSHPD[5]] projects to comply with Exposure C, unless justification can be made for Exposure B[6]); and

- changes to the building classifications from the previous Occupancy Category to the revised

Risk Category.

The authority having jurisdiction (AHJ) determines the building’s Risk Category. ASCE 7-10 uses three basic wind speed maps to determine a buildings’ Risk Category. The category designations are:

- Category I: buildings representing a low risk to human life in the event of a failure;

- Category II: most residential, commercial, and industrial buildings; and

- Category III and IV: buildings where failure could pose a substantial risk to human life or essential service facilities.

A registered architect or professional engineer should review and determine the wind loads. Based on revised calculations and wind speeds shown in ASCE/SEI 7-10’s updated maps, these speeds can be converted into appropriate load requirements for components and cladding. Building codes’ components and cladding sections typically address exterior soffits.

Construction projects must meet a Seismic Design Category (SDC) as specified by an engineer or architect. Each category determines specific product performance and installation methods required by code to withstand certain levels of seismic activity. (For more on earthquakes and soffits, see “Specifying Seismic Ceiling Safety” by Tony Ingratta, in the September 2012 issue of The Construction Specifier. To read the article, visit www.constructionspecifier.com[7] and select “Archives.”)

[8]

[8]Photos courtesy Chicago Metallic Corporation

Positive and negative pressures

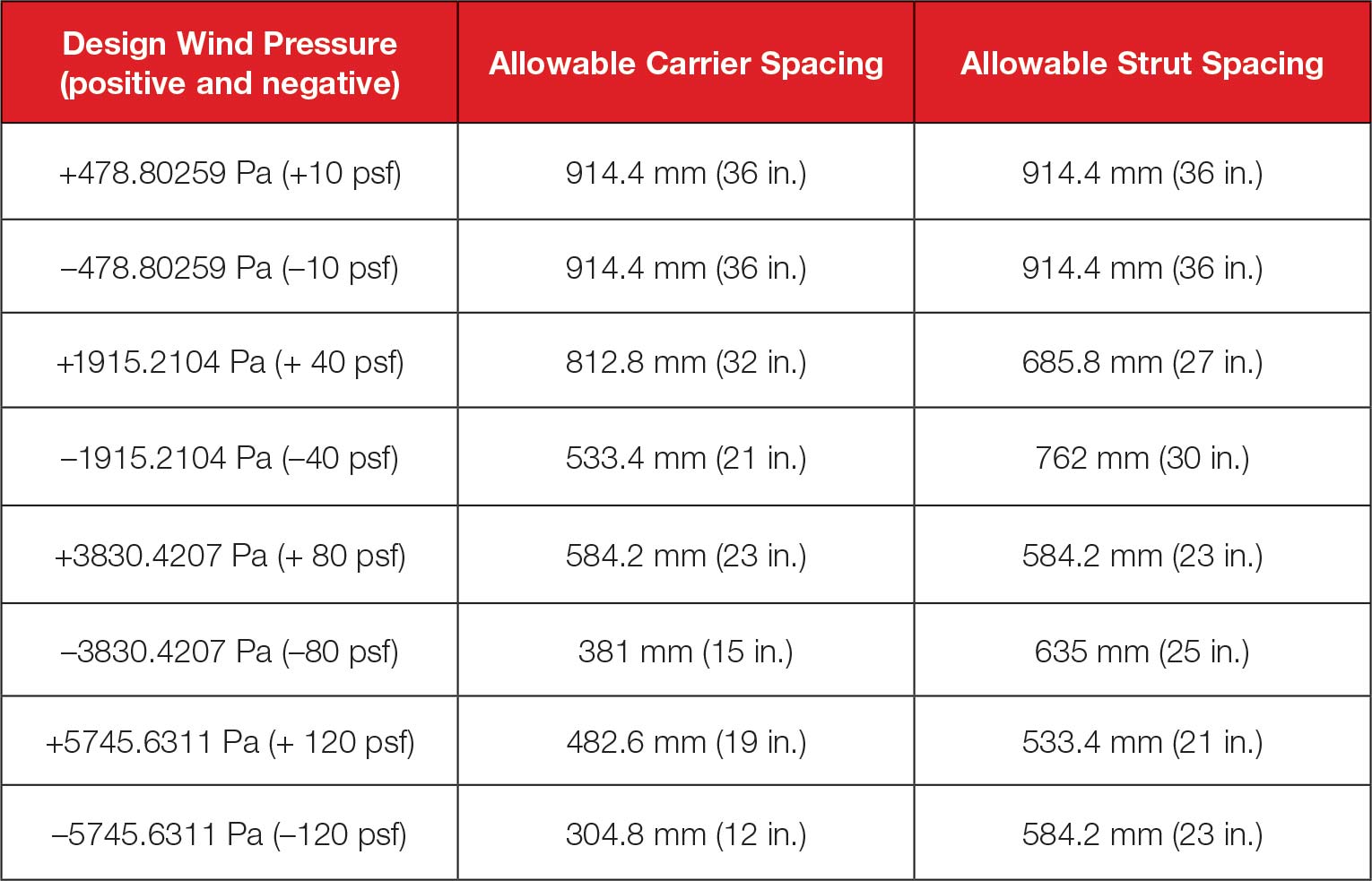

Specifiers should request metal ceiling manufacturers’ wind load technical data for the complete exterior soffit system, including suspension, panels, and structural supports. Also, laboratory test reports and assembly designs indicating both positive and negative air pressures should be requested.

When wind interacts with a building, both positive (uplift) and negative (suction) pressures simultaneously occur. These pressures also affect allowable carrier and strut spacing for metal ceiling systems in exterior soffits. Spacing requirements vary for different panel sizes, material thickness, manufacturers, and applications.

Collaborating with the manufacturer early in the design and specification process minimize confusion, ensuring long-lasting performance. By communicating the desired aesthetic, performance, schedule, and budget requirements early in the project, the manufacturer can ensure the product is engineered to meet these needs and can work with the installing contractor to guide them in proper installation, documentation, and inspection. UL conducts laboratory testing of metal ceiling systems for exterior soffits to verify a manufacturer’s claims meet industry standards for resistance to uplift forces.

[9]

[9]UL ratings

Per UL’s classification for “Roofing Systems, Uplift Resistance” (i.e. TGKX):

Roof Deck Constructions Classified for Uplift Resistance have been investigated for damageability from both external and internal pressures on the deck associated with high velocity winds. …ANSI/UL 580. The ANSI/UL 580 test method subjects a 3.05 x 3.05-m [10 x 10-ft] test sample to various static and oscillating air pressures to index performance under uplift loads imposed on roof decks.

The magnitude of the wind velocity across a roof deck and the resulting uplift pressures on a roof deck are dependent upon many factors such as wind gusts, the shape of the roof deck, edge configuration and the landscape surrounding the roof deck installation. (Search “TGKX Guide Info Roof Deck Constructions[10].”)

A UL 580 Class 30 designation indicates a system has been tested and will resist a 1436-Pa (30-psf) wind pressure (positive and negative) when installed in accordance with ASTM C636-04, Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels, and the manufacturer’s instructions. In addition to laboratory testing, UL audits the company’s manufacturing process to ensure the products are made as tested.

As an example of a Class 30 UL-rated exterior metal soffit system, UL Construction No. 630 details the following components (asterisks mark those components bearing the UL classification mark) (This information was taken from UL Construction No. 630, “Roof Deck Constructions.”):

Steel framing members*

The system used to support the soffit consists of the following components:

- main runner: * nominally 3.6 m long by 19 mm wide (12 ft by 3/4 in.) spaced 610 mm (24 in.) on center (oc) supported by hanger wire (Item 2) spaced 1220 mm (48 in.) oc;

- cross tees: * nominally 610 mm (24 in.) long; spaced 1220 mm (48 in.) oc; installed perpendicular to main runner;

- perimeter channel: * channel-shaped 63.5 mm (2 1/2 in.) deep with 19-mm (3/4-in.) legs; 0.6-mm (0.02-in.) thick aluminum; fastened to walls with 25-mm (1-in.) long steel screws spaced maximum 610 mm (24 in.) oc;

- main runners (Item 1A) and cross tees (Item 1B) attached to top leg of channel using one #7 minimum size, 11-mm (7/16-in.) screw into bulb of component;

- hold-down insert: channel-shaped hold-down insert 63 mm (2 15/32 in.) deep with 19-mm (3/4-in.) legs, 0.6-mm (0.02-in.) thick aluminum, nested inside perimeter channel (Item 1C) to hold down perimeter panels;

- inserts fastened to wall using two 25-mm (1-in.) long steel screws spaced 305 mm (12 in.) oc; and

- downbrace: as shown in Figure 1, downbraces are spaced 1219 mm (48 in.) oc along main runners and fastened to main runner with two 4.2-mm (0.17-in.) 8-gauge by minimum-sized 12.7-mm (1/2-in.) self-drilling screws; the downbrace can be notched to fit over bulb of main runner as an alternative to method for uplift applications (Item 1Eb), and the optional downbrace clip used in conjunction with downbrace and main runner must be fastened with six 3.8 mm (0.15 in.) 7-gauge by 11.1-mm (7/16-in.) screws.

[11]

[11]Data courtesy Underwriters Laboratories (UL) Construction No. 630

Hanger wire

Located directly over main runners spaced 1219 mm (48 in.) oc, the hanger wire is fastened to supports (Item 3) with an eyebolt or other appropriate connector the diameter of wire is to be 2.7 mm (0.12 in.), 12 gauge. Hanger wire must coincide with compression post (Item 1E) locations.

Supports

Supports are any structural steel, wood, or other type member capable of supporting soffit construction at a spacing as required to support soffit load and withstand uplift load.

Panel*

Panels must be 610 x 610 mm (24 x 24 in.), 0.5-mm (0.02-in.) thick steel, or 0.7-mm (0.03-in.) thick aluminum. End-joints are perpendicular to main runners (Item 1A). Side-joints are centered on the face of the main runners. Panel side-joint legs snap into face of main runners.

Panel retention clip*

The panel retention clip must have a minimum diameter of 1.6-mm (0.06-in.) steel wire. Clips fasten panel end-joint legs to main runners and occur at all panel end-joint leg intersections with main runner.

[12]

[12]‘Green’ design and colorful finishes

The exterior metal soffits’ composition not only offers enduring performance and aesthetics, it also offers sustainable design attributes. According to the Aluminum Association (AA), the material is infinitely recyclable with 75 percent of all aluminum ever smelted still in use. Metal ceiling systems can approach 100 percent recycled material content and are 100 percent recyclable at the end of their usefulness as an exterior soffit. Additionally, it is currently estimated that more than 90 percent of aluminum used in buildings is recycled after service, making it one of the most recycled building materials in the world.

Further supporting green goals, the aluminum panels may be finished with baked enamels, anodize or powder-coated paint containing no VOCs. Functional, painted coatings in standard black, white, and silver colors remain the most popular choices, but a broad palette of hues and patterns are available for bold designs. Solid, painted finishes span the spectrum of amethyst to emerald, or true blue to cardinal red. Patterned, painted finishes include those mimicking wood grain or metal. Anodize finishes emphasize a sleek, metallic appearance in silver to copper tones and in reflective chrome or brass.

[13]

[13]Care and cleaning

Throughout the building’s life, the finished metal soffits require minimal maintenance to retain the intended look and performance. Some soiling or smudging of a component’s finish is bound to happen. To ensure they are cleaned appropriately, manufacturer’s instructions should be followed. Recommendations may include:

- A mild, non-abrasive cleaning agent is typically used for cleaning painted or reflective surfaces. Abrasive cleaning agents should not be employed

as they may scratch, mar, alter, discolor, and/or remove the finish. - Before cleaning the finish, a trial test should be performed on a section that will be hidden from view once installed. This ensures the cleaning agent selected is appropriate and will not damage the finish.

- Once an appropriate cleaning solution has been selected, care should be taken to only use the necessary amount. Ceiling components should not be soaked in the solution.

- A clean, soft sponge or cloth should apply the cleaning agent to ensure the applicator does not contain any abrasive elements that may damage the finish in question.

- Any excess cleaning solution should be removed immediately so it does not dry and leave a residue. In the event a large area needs to be cleaned, it is advisable to break the area down into smaller, more manageable sections so time is available to complete each cleaning cycle phase.

- After cleaning the soiled or smudged area, the surface should be wiped with a dry, soft cloth to remove any residual cleaning solution and dry the area. A damp cloth should be used to remove any residue left behind by a dry cloth.

- After the components are clean, a few minutes should be dedicated to air drying before installation. The clean components must be dry because other ceiling materials, such as ceiling board or insulation that come into contact with the cleaned components, can be susceptible to damage from moisture.

Conclusion

Since each building and its environment are unique, special attention must be given to designing an

exterior soffit. Codes, budgets, and longevity all must be taken into account, along with the design intent. With proper installation and maintenance, a metal ceiling soffit will perform as planned for many years—protecting the building itself from water and pest damage, and also providing safety for occupants and owners.

Edward Williams is a manager for Chicago Metallic Corporation’s metal ceilings unit. He has more than 30 years of experience in manufacturing ceiling systems for commercial spaces, partnering with owners, designers, and installing contractors. Williams is an affiliate of the International Interior Design Association (IIDA). He can be contacted via e-mail at williamse@chicagometallic.com.

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_MA_Fenway_Planostile.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/soffit_Chart.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_DE_ChristianaMall_Planostile.jpg

- wind speed maps: http://publicecodes.cyberregs.com/icod/ibc/2012/icod_ibc_2012_16_par090.htm

- OSHPD: http://www.oshpd.ca.gov

- Exposure B: http://publicecodes.cyberregs.com/icod/ibc/index.htm

- www.constructionspecifier.com: http://www.constructionspecifier.com

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_TN_VetNatlCemetary10.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_FL_USFMarshallStudCtr1_Planar.jpg

- TGKX Guide Info Roof Deck Constructions: http://database.ul.com/cgi-bin/XYV/cgifind.new/LISEXT/1FRAME/index.html

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/soffit_Figure-1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_FL_Tampa_PMacro.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/CMC_OK_TransitStation_Planar.jpg

Source URL: https://www.constructionspecifier.com/designing-metal-ceilings-for-exterior-soffits/