Insulating glass unit spandrels

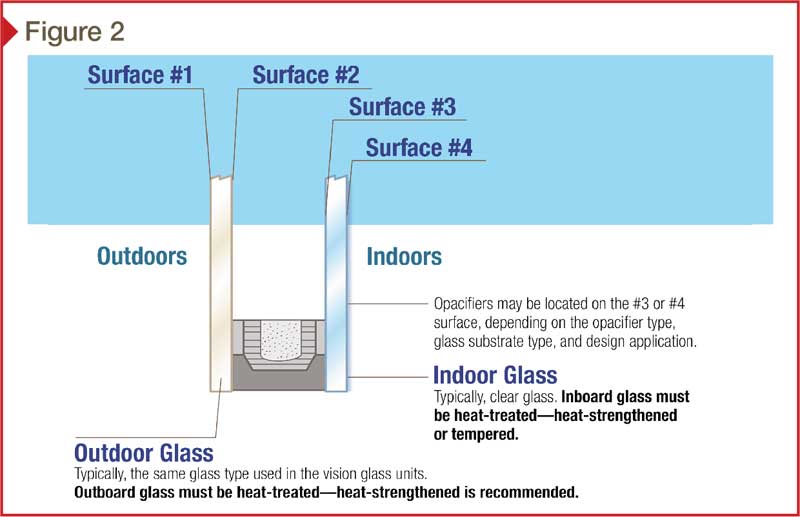

IGU spandrels are fabricated with an opacifying material applied to the third or fourth surface of the indoor glass lite, labeled 3 and 4 in Figure 2.

As these types of spandrels are designed to function like conventional IGUs, with the goal of improving a building’s energy efficiency, they are commonly specified with low-emissivity (low-e) coatings.

When this is the case, specifiers must give special consideration to which surface locations of the IGU are specified for the low-e coating and the opacifier because of the potential these materials have for elevating temperatures within the assembly. For IGU spandrels with low-e glass, the recommended location for the opacifying material is the indoor surface of the indoor lite of glass (Surface 4 in Figure 2).

Another design alternative is to place the low-e coating on Surface 2 of the IGU and the opacifier on Surface 3. As the low-e coating, opacifier, and sealants occupy the same space in this type of spandrel assembly, it is critical to confirm their compatibility with their respective manufacturers.

In some instances, it is possible for an improper combination of materials in the IGU air space to produce volatile organic compounds (VOCs), which can then condense on the low-e coating and cause it to degrade, voiding any applicable warranty.

Precautions should also be taken with spandrel assemblies combining low-e coatings and medium- to dark-colored opacifier coatings. Depending on their location and orientation to sunlight, it is possible for these spandrel designs to generate exceedingly high glass temperatures that can expose the assembly’s interior lite to potentially destructive levels of thermal stress.

Proper design will mitigate the potential for excess concentration of solar heat within the spandrel assembly. The location of the insulating material can be adjusted, and suitable levels of air circulation behind the IGU enabled.

Photo © Kris Vockler. Photo courtesy ICD High Performance Coatings

As with monolithic glass spandrels, using heat-strengthened glass for both of the lites in the IGU is recommended. Additionally, if the outdoor glass lite of any vision unit on a building façade is tinted, the outdoor lite of any adjacent spandrel units should be the same tint, and a neutral-color opacifier should be specified for Surface 3 of the indoor lite. Doing so is primarily for appearance, although it is important to note tinted glass can contribute to a thermal stress risk because of its increased solar absorption. For this reason, it usually requires heat-treatment.

Insulation and glass recommendations

As the name suggests, insulating materials are typically used in spandrel IGUs. Depending on the glass type and the recommendation of the spandrel fabricator, insulation may be applied directly to or positioned 25 to 50 mm (1 to 2 in.) from the glass surface.

Similar to monolithic glass spandrels, if the insulation material is to be applied directly to the glass surface, specific recommendations regarding its compatibility with the glass, sealants, and other materials inside the spandrel IGU should be solicited from the participating suppliers.

Given that insulation is typically designed to trap and potentially enable solar heat buildup, design professionals should consider using fully tempered glass for the interior lite of the spandrel IGU. This reduces the probability of thermal stress-related breakage, and even if breakage does occur, the exterior layer should prevent fall-out. However, fully tempered glass should not be used for the exterior ply of an IGU unless mandated by code, because of the fall-out potential if it breaks. As always, heat-strengthened glass is recommended for the exterior lites of these units.

Shadow box spandrels

Shadow box spandrels are typically specified for applications where achieving a color match between the vison glass and spandrel glass on a building façade is desired.

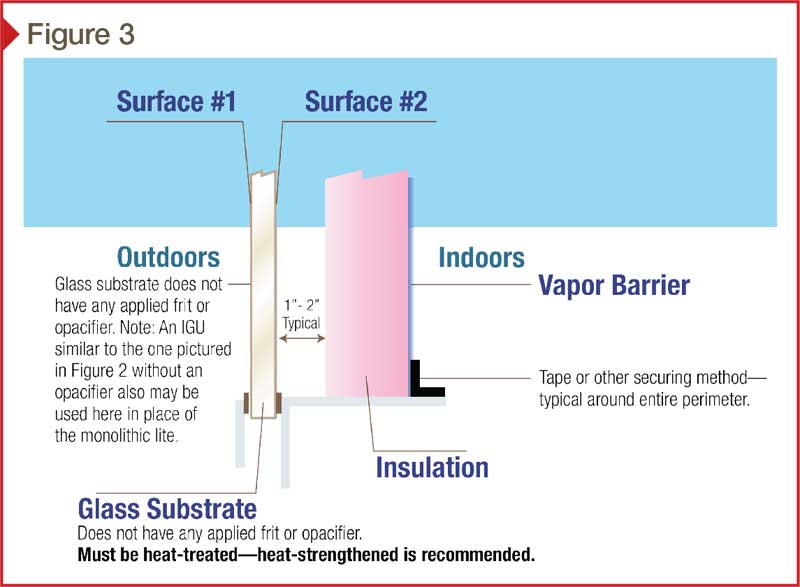

As shown in Figure 3, a shadow box spandrel will typically incorporate:

- a monolithic lite of tinted or low-e coated, heat-treated glass without an opacifier—usually the same color as the adjacent vision glass; and

- an insulation assembly made with black or dark-colored, rigid foil-backed insulation material installed 25 to 50 mm (1 to 2 in.) behind the spandrel glass, with the foil backing facing the interior of the building.

Image courtesy Vitro Architectural Glass

To completely seal each spandrel glass perimeter, create a moisture/vapor barrier, and block the entry of stray interior light into the spandrel area, the foil surface of the insulation should be secured to the interior surfaces of the glazing system. This is typically done with aluminum tape.

Given that insulation material tends to be dark and even in texture—and because the glass has reduced light transmittance—it is extremely difficult to see insulation through the glass of a shadow box spandrel, except under rare daylighting or sky-viewing conditions.

Shadow box spandrels are appealing because of their color-matching versatility, but architects, designers, and specifiers should be aware of the field-related issues common to these products, and work with suppliers to address them.

It is important to note thermal and optical performance values are calculated using steady-state conditions, and do not take into account the potential dynamic conditions that could exist in the space between glass and insulation in a shadow box spandrel design.

Is there a way to remove the ceramic frit from spandrel glass?