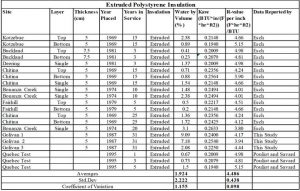

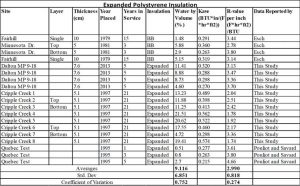

Overall, the EPS insulation was found to collect moisture more quickly and gather more throughout its time in use. For the EPS samples collected across the different periods, the non-weighted average water by volume collected was 9.12 percent. XPS insulation also gathered moisture when left in situation. The non-weighted average of moisture collection for the material was 1.9 percent water by volume. The non-weighted average compares all the samples found without applying significance, or weight, to multiple samples being taken in the same location at the same time. In the XPS samples examined, most water content by volume remained below five percent until the insulation had been in place for 30 or more years. The highest results reached about nine percent after 31 years in place. In contrast, EPS insulation tended to collect more than five percent by volume by the time it had been in place for five years. By the 20-year mark, EPS insulation samples were found to absorb from 10 to 22 percent water by volume.

To better understand how the elements of soil, climate, and moisture level influence moisture uptake into below-grade insulation, it is suggested, unsaturated soil mechanics can be combined with the examination of below-grade insulation. Sensors, such as soil moisture gauges or heat flux meters, could be used to improve the understanding, especially as it relates to R-value performance in different types of soil and over time.

“One of the reasons we keep doing this is because we cannot define what is going on in the soil,” said Connor. “In some of the plotted results, there can be great variability—the variability of moisture uptake from one spot to another can double or triple.” The ongoing research is trying to determine what factors are influencing that variability, he said, adding, “We are struggling to understand why—why are we getting the huge shifts? Is it the insulation or the soil?”

The role of material structure

One potential reason for the difference in moisture uptake and retention between the two different types of insulation display is thought to be material structure. Although both EPS and XPS are rigid polystyrene insulations, they do not share the same production process or internal structure.

XPS insulation is generated by mixing the material with a blowing agent and forcing it through a die as the insulation cures. The process generates a consistent, closed-cell structure without leaving internal voids.

However, EPS insulation is comprised of polystyrene beads which expand into a solid material in a mold. Since each bead is initially separate, the combination process can leave internal voids between beads.

EPS insulation may take on water faster because it is able to collect moisture in two ways versus the one of XPS. Several forces, including absorption, capillary action, and gravity may encourage liquid moisture to intrude into EPS insulation, allowing water to gather in the open gaps within the insulation’s structure. It has been posited how this potential collection path was not problematic because the material would drain, however, this does not appear to be occurring in below-grade situations. Vapor drive can also push moisture into the beads of insulation, but this process takes longer. XPS insulation, which lacks internal gaps, is unlikely to see liquid moisture uptake through capillary or gravitational force. However, vapor pressure could force the insulation to collect moisture inside individual cells, which may account for why both types of insulation are found to take on moisture when left below grade for multiple years.

The R-value of insulation over time

Moisture has a high rate of thermal conductivity, and its presence within insulating materials lowers the insulation’s thermal performance or R-value. Some of the additional moisture remains even after the insulation is dried, making it unlikely that the R-value will revert to its initial performance. For example, in EPS insulation, about 24 percent of the moisture collected following 31 years in service remained after the insulation sample was collected and dried. This is potentially a reflection of the drying process being unable to remove moisture from within the closed cells. After 21 years in service, about eight percent of the moisture collected in XPS insulation remained, following the drying process. This potentially supports the inference that most of the moisture gained by the insulation collects in internal voids, which is why EPS collects water more quickly.