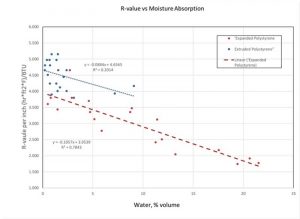

Further testing also demonstrated EPS appears to be more sensitive to moisture in terms of performance than XPS. For both types of insulation, the uptake of moisture is generally linear, as was the decline in R-value during the period examined in the study.

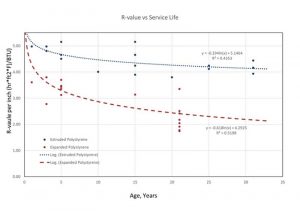

Although there is not always a high degree of correlation between R-value and service life, there is a trend for R-value to decline over time, when exposed to moisture. EPS saw a more rapid decline in R-value before becoming asymptotic to or never quite reaching an R-value of about 2.2 after a 30-year span. XPS insulation saw its R-value decline to almost 4.1 during the same period.

Calculating insulation thickness

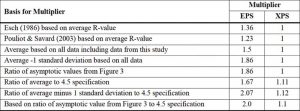

Given the discrepancy in moisture uptake, retention, and decline in thermal performance, several different methods of determining the insulation thicknesses needed to provide the intended R-value for a project’s service life have been posited.

One of the main methods created assumes XPS will not see a change in R-value over time but EPS will. This means the necessary amount of XPS is established and the corresponding thickness of EPS is determined using a ratio-based calculation—for this, multiple options have been proposed. For example, if a project needed 101.6 mm (4 in.) of XPS insulation using the average minus one standard deviation multiplier, this 101.6 mm (4 in.) would be multiplied by 1.86 to determine how thick the EPS insulation would need to be. In this example,

188 mm (7.4 in.) of EPS insulation would be needed to match the performance of the XPS insulation.

Although the current study adds data points and additional analysis regarding the performance of rigid polystyrene insulation used in harsh environments in below-grade application, no consensus has been established regarding the best method to determine exactly how thick insulation needs to be for this use.

Two primary pathways based on either the in-service R-value ratio or the in-service reduction in R-value have been created. It is possible for improved understanding of the interaction of insulation with soil-moisture characteristics to further refine the design process. As Connor said, the data suggests, relying on R-values as manufactured may not provide desired performance for a project’s intended lifespan.

Building on the research

The data from the recent University of Alaska study found moisture content within the below-grade applied insulation can vary over time. EPS samples were found to have a maximum moisture content of about 22 percent in a service life of 21 years, based on the age of the oldest samples examined and not overall material function. The XPS insulation was determined to have about nine percent maximum moisture content after 31 years of service, based on the age of samples collected rather than anticipated long-term function of the material. While both insulation types saw a drop in R-value over time, EPS was more sensitive to moisture content and saw a sharper and greater fall in R-value, dropping to 2.2, compared to the 4.1 maintained by XPS.

As demonstrated, EPS absorbs more moisture and loses R-value in these below-grade applications, behavior presumed to relate to structural properties and the inability to repel moisture and drain as posited. This resulted in preliminary recommendations of multipliers to account for the performance discrepancies when installing insulation. As a result, specifiers may see multipliers proposed in upcoming code hearings or used in the design of other applications, such as foundations and low-slope roofs, where insulation is similarly exposed to extreme moisture environments.

While the research on thermal and moisture performance has been ongoing for more than three decades, the work continues, and more attention is likely to focus on aspects of unsaturated soil mechanics to help predict moisture’s behavior in soil. Insights can help engineers select between options and create better-performing enclosures from below-grade to vegetative roof assemblies. More details on the research and work being conducted in this area are available in the research paper: Comparisons of polystyrene expanded and extruded foam insulation in roadway and airport embankments.

Notes

1 See Permafrost: Everything you need to know, by Denchak, M., NRCD. https://www.nrdc.org/stories/permafrost-everything-you-need-know#sec-where

2 Read How thawing permafrost is beginning to transform the Artic, by Struzik, E., Yale Environment 360. https://e360.yale.edu/features/how-melting-permafrost-is-beginning-to-transform-the-arctic

3 Read The fragile future of roads and buildings built on permafrost, by Baraniuk, C., BBC Future. https://www.bbc.com/future/article/20210303-the-unsure-future-of-roads-and-buildings-on-melting-ground

4 Consult Building in permafrost country: A challenge of technology, cost, and a warming climate, by Currey, J., Alaska Department of Transportation and Public Facilities. https://dot.alaska.gov/traveltopics/building-in-permafrost.shtml

5 Consult Comparison of polystyrene expanded and extruded foam insulation in roadway and airport embankments. (Report No. INE/AUTC 19.08), by Connor, B., Alaska University Transportation Center.

6 Consult Insulation performance beneath roads and airfields in Alaska (No. FHWA-AK-RD-87-17), Esch, D. C., Department of Transportation and Public Facilities.

7 Read High Density Expanded Polystyrene Boards as Road Insulation, Phase I, Performance Evaluation of Expanded Polystyrene on Road 161 in Saints-Martyrs-Canadiens, by Pouliot, N., & Savard, Y., Performance Follow-Up Report, Quebec: Ministry of Transport, Quebec.

8 See Review of moisture behavior and thermal performance of polystyrene insulation in building applications, by Cai, S., Zhang, B., & Cremaschi, L., Building and Environment, 123, 50–65. https://doi.org/10.1016/j.buildenv.2017.06.034

9 Consult Standard Test Method for Water Absorption of Rigid Cellular Plastics (ASTM D2842-19), ASTM International, https://www.astm.org/d2842-19.html

10 Consult Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus, ASTM International, https://www.astm.org/standards/c518

Author

Author