Diverse finishes maximize granite’s potential

by Katie Daniel | July 5, 2016 9:07 am

by Jerry Robel

Well-known for its beauty and durability, granite offers numerous design benefits. However, a less familiar advantage is its versatility—particularly when multiple finishes are applied. Today, design teams are selecting one granite type, choosing several finishes, and achieving great variety, texture, and appeal.

It is a common misconception a project with only one type of stone produces a monotonous look. As a result, the search for variety often leads designers to select numerous stone colors, which can stretch a budget. Additionally, design teams may have a particular appearance in mind, but fail to realize the various available finish options to achieve it. This is often due to a lack of education. The stone industry is highly specialized, and many outside of it do not realize the possibilities finishes create. To help educate the industry, leading stone manufacturers offer lunch-and-learn sessions with samples. However, visits to fabrication facilities present the best learning method, as design teams can see the various benefits, appearances, and functionality achievable with different finishes.

One such benefit is the more subtle contrast of one stone type with multiple finishes versus a more stark contrast of different stones. When multiple finishes of the same stone are used throughout the project, subtle variations coordinating the entire look are created. Additionally, using one stone can reduce the number of pieces requiring installation, which also reduces the joints between pieces. Therefore, a more defined break from finish to finish is achieved.

Sometimes a change in finish is used as a design element. For example, a hardscape might change finishes to signal a change in space, such as moving into a seating area. In other cases, a different finish achieves the functionality a project requires (i.e. when meeting the Americans with Disabilities Act [ADA] requirements). While polished or honed finishes alone do not generally meet ADA requirements, the application of a flamed or sanded finish in conjunction with a polished or honed may achieve the minimums.

Design teams wishing to incorporate a variety of finishes should coordinate carefully with their granite fabricator. In the following examples described throughout this article, the design teams chose a variety of finishes with the same material to achieve functional coordinated spaces.

Multiple finishes offer coordinated look for cathedral hardscape

In Wheeling, West Virginia, the Roman Catholic Diocese of Wheeling-Charleston recently initiated a major reorganization project for the campus of St. Joseph Cathedral. The diocese had outgrown its existing 1950s-era chancery where the diocese’s administrative offices are housed. For the project, the design team chose one granite color in multiple finishes to coordinate the space.

In addition to the cathedral, the existing campus had numerous buildings serving the area’s Catholic community, including a building containing the chancery, rectory, and archives, a high school, and an elementary school.

Plans for the reorganization included closing the existing elementary school and renovating the building into a new chancery.

The design involved the construction of a central courtyard and garden—creating public spaces for the community’s enjoyment. A new fountain in the courtyard would add the elements of movement and sound for an inviting and serene gathering area.

In 2011, the diocese closed the elementary school and commenced renovations for the new chancery and public space. An existing courtyard of concrete unit pavers and wall systems was removed and new paving in granite was installed. Granite was selected not only for its beauty and durability, but also for its versatility.

Black-colored granite was used for many elements in the project—from fountains and pools to paving and steps—explained Michael Stern, principal at Strada Architecture.

In total, the project included approximately 557 m2 (6000 sf) of black granite in three finishes. The series of finishes chosen offers subtle variations in color, tone, and texture.

For pavers and stair treads, the design team selected a semi-rough finish, textured to sparkle in the sunlight and reveal vibrant colors in a deep, rich background. This particular finish also provides a suitable, slip-resistant surface for pedestrian areas.

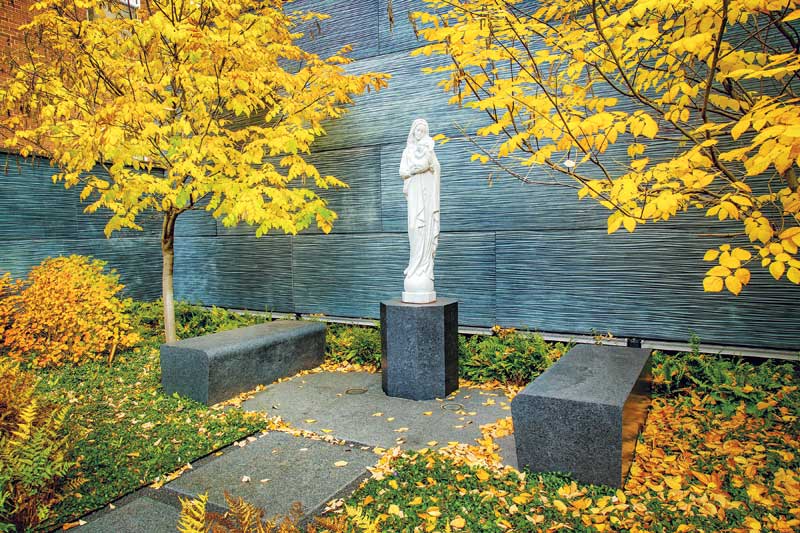

A hone finish was selected for cubic benches in the garden area, the fountain’s paving and coping, and the main fountain feature. It produces a slightly darker shade with less texture than the finish used on the steps. This finish also provides the ideal appearance for a pedestal of a Virgin Mary statue, which stands outside the archives building.

The lightest shade of the three finishes was chosen for the pedestal of the St. Joseph statue located in the plaza, and as the plaza paving around the tree bosque. This slightly rough-hewn texture highlights the stone’s reflective crystals, enhancing and contrasting with the depth of the darker colors.

“By varying the finishes, we created different looks with the same stone,” said Stern.

The base of the existing rectory adjacent to St. Joseph Cathedral is sandstone, which was selected for key design elements on the chancery’s new wing. In addition to sandstone, other natural stones such as limestone are present at the site.

“With the variety of natural stones at the site, the use of granite for all walkway areas creates a uniform contrast on the ground plane,” said Stern. “Granite was the unifying material at the site—tying together all the other materials.”

Completed in 2014, the project for the Diocese of Wheeling-Charleston has created an updated, modern campus that better fits the diocese’s needs.

Finishes at Dilworth Park

Located in Philadelphia’s Center City District, Dilworth Plaza recently received a much-needed renovation. The same black granite—in numerous finishes—helped achieve design goals, transforming what was once an inaccessible, multi-level plaza into a vibrant, open civic space above Philadelphia’s main transportation hub.

Renamed Dilworth Park, the 1911-m2 (20,572-sf) gathering spot features a modern and historic design fusion, much like Philadelphia itself. Nearly 9290 m2 (100,000 sf) of finely carved and crafted granite masonry was used throughout the exterior, including paving, walls, and benches. According to the design team, granite was selected for its ability to provide a contemporary look while complementing the historic surroundings.

The black granite color provided an ideal background to the almost bluish tones of the city hall’s granite, limestone, and marble exterior. The 50-mm (2-in.) thick pavers in the plaza area have varying lengths and widths, with the most common paver measuring 0.9 m long by 0.4 m wide (3 by 1 1⁄2 ft). The majority of pavers feature a slightly rough-hewn finish, ideal for pedestrian areas. Around the benches, a finish produced with heavy water treatments was selected to reveal the radiant crystals within the stone’s surface through a dramatically coarse texture. According to the design team, this texture is a design element indicating to pedestrians they are approaching a bench.

Photos courtesy OLIN/Sahar Coston-Hardy

The 14 large, curvilinear benches along the plaza area are constructed of granite veneer and capstones of solid granite in the same finish as the surrounding pavers. In total, 603-m2 (6500-sf) of granite was used for the benches. The benches and their smooth, curvilinear forms are designed to respond to the changes in grade when entering the plaza. As park visitors travel up and down the plaza, the benches curve and hold a grade in a way that calls to mind a giant balustrade on a stair. The benches’ beautiful curved forms change constantly in radius, height, and width—a modern version of stonework from generations past. Benches and capstones were installed with cranes, due to their large size.

Installation of the pavers proved complicated because of the stone’s location atop the city’s transportation system. Essentially, the park is a roof and is on a nearly flat elevation. Designers had to determine the best way to channel stormwater from one end of the park to the other. As such, the stonework had to maintain sufficient tolerance to achieve the required drainage characteristics. Exceptional fabrication with computer numerically controlled (CNC) technology achieved the precisely shaped stones meeting the specifications needed for drainage.

Other installation challenges included the numerous finishes and textures of the pavers. With three different finishes running together in bands throughout the plaza, the design, fabrication, and installation teams had to carefully coordinate and catalog each piece of stone for it to be placed in the correct location.

As a new ‘front door’ to the city, Dilworth Park is a beautiful, inviting public space. The Dilworth Park project re-establishes William Penn’s original Center Square as the heart and soul of a historic city.

Conclusion

With so many finish options available, it is critically important to work closely with a manufacturer’s representative who will explain the possibilities and provide sampling. A visit to a fabrication facility to see the finishes being applied will offer an invaluable opportunity to learn about the possibilities. In the end, the result is the architect or owner’s vision is realized with the beauty of stone as the backdrop.

Offering a beautiful, durable, and low-maintenance surface, granite is suitable for interior and exterior applications. One stone can take on a completely different appearance when a different finish is applied. Using multiple finishes of the same stone can create subtle variations that coordinate the project without going overboard. A transition to a different finish can serve as a design element, signaling a change. The options in finishes go far beyond polished or honed. Understanding the many differences and options can open new doors of design possibilities.

Jerry Robel has specialized in the natural stone industry for more than 30 years. As director of sales at Coldspring, Robel works with the architectural and design communities to meet their natural stone needs, and with cemeteries for memorial product and cemetery development needs. He can be reached at jrobel@coldspringusa.com[1].

- jrobel@coldspringusa.com: mailto:jrobel@coldspringusa.com

Source URL: https://www.constructionspecifier.com/diverse-finishes-maximize-granites-potential/