First focus on the window perimeter

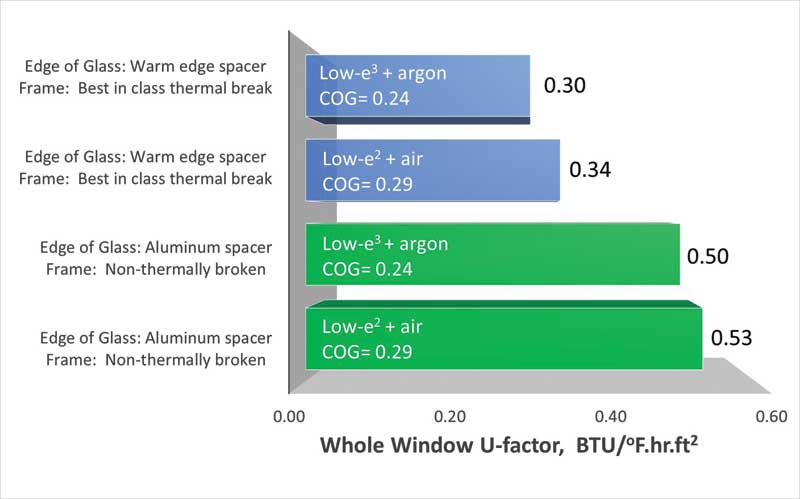

Figure 3 shows how the whole-unit U-factor varies with COG, frame, and EOG (spacer) performance. It demonstrates how the perimeter of the window dominates the overall U-factor performance. In a poor-performing, non-thermally broken frame, using a very good glass package with a low COG U-factor hardly changes the overall window performance. (The overall U-factor changes by only five percent when changing the glass package from dual-pane glazing with standard double silver low-e with air to a package with triple silver low-e and argon.)

The most impactful change to the overall U-factor (i.e. a 36 percent total decrease) comes by switching the frame from non-thermally broken to thermally broken and replacing a highly conductive aluminum spacer with a low-conductance (warm-edge) spacer. Once the frame and the EOG performance have been enhanced, improving the COG U-factor makes more of an impact on the overall window performance—an 11 percent reduction when changing from COG U-factor of 0.29 to 0.24 Btu/F•hr•sf.

When specifying a fenestration system, the corollary is the focus should be on improving the performance of the frame and EOG before specifying the glass package. Having a high-performance perimeter enables achievement of a high-performance window system; it also provides much greater flexibility in glass choice because the very highest COG U-factor performance may not be needed. In other words, a great frame can achieve the same performance with dual-pane glazing as a poorer-performing frame with triple-pane glazing. Figure 2 provides an example in comparing Window Wall #5 (good frame with double glazing) with Window Wall #3 (poorer frame and triple glazing).

Condensation resistance

Condensation on interior surfaces of windows can comprise a significant issue. Depending on the severity, this can result in water damage to both windows and nearby walls, and harbor mold growth that harms IAQ.

Condensation occurs when the temperature of the interior surfaces of the window falls equal to or below the dewpoint temperature of the interior air. This is the temperature at which water vapor, when cooled, begins to condense. The higher the building’s interior humidity, the higher the dewpoint. In such cases, condensation occurs at a warmer window surface temperature.

In winter, the absence of a barrier to heat transfer between a window’s outer and inner surfaces means the interior surfaces will become significantly colder than the ambient room temperature. (The reverse is true in summer.) As a result, condensation may occur on the cold surfaces, the extent of which depends on the window’s thermal characteristics, the exterior temperature, and the interior ambient humidity and temperature.

Condensation rating systems

The most common rating systems for assessing a window’s ability to resist condensation are condensation resistance factor (CRF) and condensation resistance (CR).

CRF is a value (generally between 30 and 80) determined by actual measurements of frame and glass temperature under defined test conditions. Developed by the American Architectural Manufacturers Association (AAMA), it is calculated by using the lower of a weighted average of the frame temperatures or the average glazing temperature. (For more on AAMA’s CRF calculation method, visit www.aamanet.org/upload/userguide.pdf.) Higher numbers are indicative of better condensation resistance.

The other metric, CR, was created by NFRC as an optionally reported performance value on its standard rating label. It has a scale of 1 to 100, where higher numbers represent higher resistance to the formation of condensation. It can be derived by using physical measurement, but more generally it is calculated. (More can be found in NFRC 501-2017, User Guide to the Procedure for Determining Fenestration Product Condensation Resistance Rating Values, and NFRC 500-2017, Determining Fenestration Product Condensation Resistance Values.)

Neither CRF nor CR are absolute scales and thus they provide only a relative comparison of the condensation performance between windows. Moreover, they are not correlated, so comparisons can only be made for products within each of the two rating systems and not between them. While there are criticisms of both rating scales concerning their wide applicability and interpretability, they remain the only easily accessible tools for assessing resistance to condensation for windows. (For example, see Martin Holladay’s October 2012 article, “Musings of an Energy Nerd,” posted on Green Building Advisor. Visit www.greenbuildingadvisor.com/blogs/dept/musings/rating-windows-condensation-resistance.)

It is also very important to note there is no direct or linear correlation between either of these condensation resistance metrics and window U-factor. In fact, in some cases, there may be an inverse correlation. A key reason for this is the extent of condensation formation is determined primarily by thermal bridging at the frame and EOG, whereas U-factor is a weighted average of the whole window’s thermal transmittance.