Effects of acoustical ceiling panel type: Vertical sound isolation

by sadia_badhon | April 30, 2021 3:15 pm

[1]

[1]by Gary Madaras, PhD

Preventing noise from transmitting between enclosed rooms is important in buildings. A conversation between a doctor and patient in a medical exam room, or between a lawyer and client in an office, should be confidential. People in adjacent rooms should not be able to listen to the private information being exchanged.

Inter-room noise isolation applies to enclosed rooms horizontally adjacent to one another on the same floor. Much is known about constructing partitions, whether they are made of masonry or gypsum wall board attached to metal or wood studs, to achieve the desired level of noise isolation. There have been multiple, comprehensive studies on the noise isolating performance of partitions (for more information, read California Department of Health Services’ “Catalogue of STC and IIC Ratings for Wall and Floor/Ceiling Assemblies;” available through the Western Wall and Ceiling Contractors Association’s Technical Services Information Bureau[2]; National Research Council Canada [NRC] Institute of Research in Construction’s [IRC’s] “Gypsum Board Walls: Transmission Loss Data, Internal Report” [IRC-IR-761, March 1998] and “Sound Transmission Through Gypsum Board Walls: Sound Transmission Results” [Internal Report IRC-IR-693, October 1995]; Canada Mortgage Housing Corporation’s “Noise Isolation Provided by Gypsum Board Partitions;” and “Design Data for Acousticians” by Architectural and Construction Services of United States Gypsum [February 1985]).

Noise isolation is also important between vertically adjacent rooms. For example, students being energetic in their classroom on an upper floor of a school building should not disturb peers concentrating in the library below them. In these cases, the floor construction is the primary building element controlling the amount of noise transmitting between rooms. In buildings with ceilings, it is the combination of the floor and ceiling assembly that establishes the overall noise isolation performance between rooms.

There is far less information and test data about the noise isolation performance of floor-ceiling assemblies compared to partitions. The information that does exist is mostly for multifamily residential buildings with wood framing/flooring and gypsum board ceilings. For nonresidential buildings with concrete structural floors and suspended acoustic panel ceilings, the information and test data are limited.

[3]

[3]Without these accurate tests, architects and acousticians have followed a few general ‘rules of thumb.’ One of these is to achieve greater vertical noise isolation—the acoustic ceiling panels suspended below the concrete slab should:

- be made of a certain material, such as wet-felted mineral fiber;

- have a certain minimum weight, for example, 5 kg/m2 (1 psf); and

- earn a minimum ceiling attenuation class (CAC) rating of 35.

Testing conducted for this article used a consistent, baseline, concrete floor slab and three suspended acoustic panel ceilings of different material types, weights, and acoustic performances to investigate the potential effect an acoustic ceiling has on the noise isolation performance of the overall floor-ceiling assembly.

Requirements in building standards

Most acoustic standards, guidelines, and rating systems have minimum noise isolation requirements between enclosed rooms. They are most often expressed as sound transmission class (STC) ratings for interior partitions, doors, windows, and floor-ceiling assemblies (read G. Madaras’ “A Guide on the Four Categories for Acoustics Criteria in Building Standards and Guidelines”).

Guidelines by the Facilities Guidelines Institute[4] (FGI) for the design and construction of healthcare facilities require floor-ceiling assemblies between patient rooms in hospitals to achieve a minimum STC 50 rating (see Table 1.2-6 in the 2018 volume for hospitals).

The American National Standards Institute/Acoustical Society of America (ANSI/ASA) S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools, requires floor-ceiling assemblies between classrooms to achieve a minimum STC 50 rating (see Table 4 in the 2010 version).

The General Services Administration/Public Building Service (GSA/PBS) P100 Facilities Standards[5] for federal office buildings require floor-ceiling assemblies between offices achieve a noise isolation class (NIC) rating of 50 (see section 3.5.3.4 in the 2018 version).

NIC is similar to STC as both measure the noise isolation performance of a building element or assembly. STC is measured in a laboratory and is used as reference during design. NIC is measured in the field after construction is complete.

Due to the consistent use of STC 50 for floor-ceiling assemblies in acoustic standards for healthcare, education, and office buildings, the research for this article also uses STC 50 as a goal reference criterion.

[6]

[6]Ceiling testing process

Acoustic testing was performed at NGC Testing Services in Buffalo, New York, in January 2020 by a senior test engineer. The laboratory is accredited by the National Voluntary Laboratory Accreditation Program (NVLAP) (Laboratory Code 200291-0). STC tests were performed according to ASTM E90, Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements, and E413, Classification for Rating Sound Insulation.

A baseline STC test was performed on a 133-mm (5 ¼-in.) thick, normal weight, concrete floor slab (293 kg/m2/60 psf) poured onto a steel deck with 38-mm (1 ½-in.) deep flutes (20 kg/m2/2 psf). Vinyl composite tile (VCT, 4 kg/m2/0.80 psf) flooring was adhered to the top of the concrete slab. The total weight of the floor construction was 307 kg/m2 (62.8 psf). There was no acoustic panel ceiling suspended below the floor construction for the baseline test.

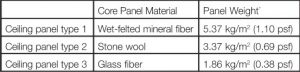

Following the baseline test, a standard, 24-mm (15/16-in.), metal, tee-bar, ceiling grid was installed 508 mm (20 in.) below the concrete floor and remained in place for all subsequent STC tests. Three different types of acoustic ceiling panels were installed in the suspension grid and tested independently (Figure 1). All three ceiling panel types were 610 mm (24 in.) wide (nominal) x 610 mm (24 in.) long (nominal) x 19 mm (3/4 in.) thick (nominal) with painted white finishes and square, lay-in edges. The main differences between the ceiling panel types were the core material types, panel weights, and acoustic performances.

[7]

[7]

* Panel weights are manufacturer-declared values. Actual weights of the tested panels varied slightly, normally less than the declared values, but this would not affect the results or conclusions.

CAC is a measure of a ceiling panel’s ability to attenuate noise transmitting through a room’s acoustic ceiling, over a partition terminating in height at the level of the suspended ceiling (creating a shared plenum space above the ceiling), and back down through the acoustic ceiling in the adjacent room. It is a double-pass rating as the sound passes through the ceiling two times. While CAC is not applicable directly to this article’s topic of single-pass vertical noise isolation in the presence of a contiguous concrete slab, ratings are provided because industry rules of thumb, even though not technically accurate, include the use of CAC 35+ panels to help with controlling vertical transmission of noise through floor-ceiling assemblies. The CAC ratings of the ceiling panels ranged from 20 to 35, representing the most common performance range used in the industry (CAC ratings for the ceiling panels were based on manufacturer declared values. CAC tests on the panels were not performed).

The noise reduction coefficient (NRC) is the amount of sound absorbed by a surface like an acoustic ceiling panel. It varies between 0.0 (no sound absorption) and 1.0 (a lot of sound absorption). Ceiling panels with higher NRC ratings decrease noise levels and reverberation, making speech in enclosed rooms more intelligible and preventing noise from traveling farther distances in open spaces. The NRC ratings of the ceiling panels ranged from 0.75 to 0.95. This range represents the mid to high range available in the industry. Low-performing panels of NRC 0.70 and below were excluded (the NRC ratings for the ceiling panels were based on manufacturer declared values. NRC tests on the panels were not performed).

Two series of STC tests were performed. For the first series, all suspension grid modules were filled with only the acoustic ceiling panels (Figure 2a). There were no light fixtures or air distribution devices implemented into the ceiling systems. For the second series of tests, nine ceiling panels were replaced by six recessed light troffers, two plaque-style supply air diffusers, and one eggcrate-style return air grille (Figure 2b). These two series of tests, with and without building service penetrations, were conducted so that any effects of the noise leaking through the penetrations on the overall vertical noise isolation, such as would be the case in real buildings, would be documented.

Color sound mapping

STC, like other acoustic metrics, measures performance of a multi-component, architectural system at different frequencies and then uses a procedure per ASTM E90 to represent the ‘average’ performance with a single number. While the single number metrics are useful for quick comparisons and some decision-making, a lot of beneficial detail is lost. Two assemblies can have the same STC rating and their performance can be perceived quite differently. Therefore, it is wise to also review the transmission loss (TL) performance at third octave band resolution, but even TL is an ‘average’ of how the whole system or assembly is performing.

[8]

[8]Neither STC nor TL can show how specific, individual components are performing relative to the others in the system or assembly. A ‘weak link,’ if present, cannot be identified. For that reason, a commercially available, sound, color-mapping system was used to create maps superimposed over pictures of each architectural test specimen. The color sound maps were created by using specialty software to combine in real-time the acoustic data from a sound intensity probe with its position data from a position tracking device.

Two different types of color sound maps were created. The first type shows sound transmission through the test specimen from a sound source located in the chamber above the floor-ceiling assemblies. The second type of sound map shows sound absorption and reflection off the ceiling systems when the sound source is in the same room below the ceiling systems.

Ceiling sound isolation performance

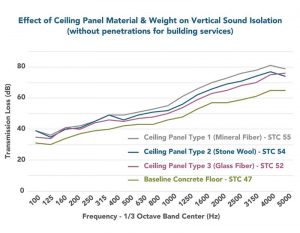

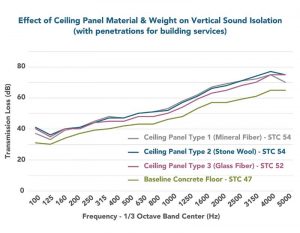

TL and STC results are provided in Figure 3 (no penetrations in the ceilings for building systems devices) and Figure 4 (penetrations in the ceilings for building systems devices). The baseline concrete on steel deck with VCT flooring on top rated STC 47, which is three points below our minimum reference goal of STC 50 based on acoustic standards, guidelines, and rating systems.

Adding an acoustic ceiling to the baseline floor increased the STC rating of the assembly, on average, six-and-a-half STC points. Adding any of the three acoustic ceiling panel types resulted in assembly ratings that were two to five STC points higher than the reference goal of STC 50. The three ceiling panel types varied by only three STC points when there were no penetrations for building systems and differed by only two STC points when the penetrations for lights, supply air, and return air were present.

Figure 5 shows a summary of both types of color sound maps for the three types of ceiling panels. The absorption (NRC) images show top row shows noise reflecting off the ceiling (red and yellow) or being absorbed by the ceiling (blue). The consistent red areas for all three ceiling types are loud noise reflecting off the painted, metal light fixtures, and supply air diffuser. It is important to note the return air grill in all three images is blue because sound is passing through the open return grille, representing perfect absorption, and not reflecting off that part of the ceiling back into the room.

[9]

[9]Ceiling panel type 1 (mineral fiber, NRC 0.75) is mostly yellow and red because it is reflecting noise more than absorbing it. Ceiling panel types 2 (stone wool, NRC 0.90) and 3 (glass fiber, NRC 0.95) are mostly blue, like the return air grille, because they are efficiently absorbing and not reflecting the noise. Slightly better absorption can be seen for panel type 3; there is less yellow and more blue.

The isolation (STC) images in Figure 5 show noise leaking through the floor-ceiling assembly. The color maps for the three ceiling panel types are very similar, which is expected since the STC ratings and TL are also alike. The interesting anomaly is the amount of sound leaking thought the return air grille.

The ceiling panels have, essentially, the same absorption characteristics on their topsides (facing up into the plenum above) as they do on their bottom sides (facing down into the room). Since ceiling panel type 1 has a lower absorption rating, noise reflects around inside the plenum more readily, leaking down through the opening at higher levels (red). This is also true, but to a lesser extent for panel type 2 (green/yellow).

The return air grille is only similar to the rest of the ceiling for panel type 3, indicating the noise is being absorbed in the plenum. This difference in noise leaking through the return air grille may produce a localized audible difference for someone directly under the return air grille, but would probably not be audible elsewhere in the room.

Conclusion

Acoustic standards, guidelines, and building rating systems most often require an STC 50 level of isolation between rooms oriented vertically to one another inside education, office, and healthcare facilities. The baseline test shows a 133-mm (5 ¼-in.) thick, 293 kg/m2 (60 psf) concrete slab cannot meet this minimum criterion by itself.

The baseline floor slab is on the thick and heavy side of the normal range for non-residential buildings. Mass law says a doubling of the mass results in a six decibel (dB) increase in noise isolation. It can then be extrapolated approximately to increase the noise isolation of the baseline floor slab from the tested STC 47 to the minimum goal reference of STC 50, the thickness and weight would need to be raised from 133 mm (5 1/4 in.) and 293 kg/m2 (60 psf) to nearly 203 mm (8 in.) and 439 kg/m2 (90 psf).

[10]

[10]This approach would take the weight and cost (including the associated ripple effects on the building structure and foundation) above the normal range for nonresidential buildings. In other words, increasing the size and weight of the concrete slab as the only noise isolating barrier between the rooms would not be practical or cost effective for most buildings.

Adding an acoustic panel ceiling below the slab, on average, increases the vertical noise isolation six-and-a-half STC points. Since absorption in the rooms below is also required to comply with maximum permissible reverberation times in the standards, the addition of an acoustic panel ceiling appears to be the wise approach for complying with both the vertical noise isolation and room acoustic requirements.

Since acoustic ceilings, on average, increase the noise isolation performance of the floor-ceiling assembly to STC 53 to 54, three to four STC points higher than the goal reference of STC 50 in the standards, the thickness and weight of the concrete slab could be decreased to save costs. Extrapolation using mass law predicts that with any of the tested acoustic ceilings, a concrete slab that is 102 mm (4 in.) and 220 kg/m2 (45 psf) should provide the STC 50 rating required by the standards. It is recommended to test this prior to application.

The results in Figures 3, 4, and 5 show that, while adding a suspended acoustic ceiling below a concrete slab makes a significant improvement in noise isolation (STC), the actual type of ceiling panel (core material, weight, CAC rating, NRC rating) does not have a meaningful impact. While some might initially consider the two STC point difference for panel type 1 compared to panel types 2 and 3 meaningful, the author suggests the difference is immaterial and imperceptible.

In fact, Figure 4 shows the lightest weight ceiling panel, type 3 (glass fiber), outperformed the heaviest weight ceiling panel, type 1 (mineral fiber) in the low 125 Hz octave band. If one is willing to say the slight differences amongst the STC ratings of the ceiling types is material, then they also should be willing to recommend and specify a lightweight glass fiber panel when trying to isolate low frequency noise in the 125 Hz octave band. Few acoustical experts would make that recommendation.

One must consider the relative weights of the components of the tested floor-ceiling assemblies. While the weights of the ceiling panels can vary substantially relative to each other, those differences in weight (2 to 4 kg/m2 [0.41-0.72 psf]) are immaterial compared to the weight of the concrete slab (293 kg/m2 [60 psf]). The concrete slab controls the noise isolation level. Adding an acoustic ceiling of any type improves the performance the same amount.

Testing shows current design rules of thumb, namely that ceiling panels should be of a certain material type, weight, or CAC rating for improved vertical noise isolation, do not hold true. In fact, the testing shows these rules may be leading to worse acoustic conditions for building occupants.

Figure 5 shows that while ceiling panel material type and weight do not affect overall floor-ceiling noise isolation performance, they impact absorption and room acoustics inside the rooms significantly. This means design professionals sacrificing NRC (absorption) in the hope of achieving higher vertical noise isolation are doing so for no real benefit. Vertical isolation is not improved and the benefits of shorter reverberation times for greater comfort, higher speech intelligibility, and privacy are not being gained.

While selecting and specifying acoustic ceiling panels for buildings, design professionals should focus on selecting the appropriate high NRC rating (read G. Madaras’ “Specifying Ceiling Panels with a High NRC[11],” published in the February 2020 issue of The Construction Specifier). As long as the acoustic panel ceiling is included in the design, architects can be confident the ceiling panel material, weight, and CAC rating is not important to the overall floor-to-floor noise isolation performance of the floor-ceiling assembly.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/0Rockfon_Library2676.jpg

- Western Wall and Ceiling Contractors Association’s Technical Services Information Bureau: https://www.tsib.org/content.asp?contentid=140.%20

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/1Rockfon_Test-CeilingInstallation7241.jpg

- Facilities Guidelines Institute: http://www.fgiguidelines.org/guidelines/purchase-the-guidelines

- Facilities Standards: https://www.gsa.gov/real-estate/design-construction/engineering-and-architecture/facilities-standards-p100-overview

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/Figure2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/4-30-2021-2-36-33-PM.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/3Rockfon_Effect-CeilingWithoutPenestrations.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/4Rockfon_Effect-CeilingWithPenestrations.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/5Rockfon_ColorMap-CeilingsPanels_vertical-option.jpg

- Specifying Ceiling Panels with a High NRC: http://www.constructionspecifier.com/specifying-ceiling-panels-with-a-high-nrc

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/04/00Rockfon_GaryMadaras.jpg

- gary.madaras@rockfon.com: mailto:gary.madaras@rockfon.com

Source URL: https://www.constructionspecifier.com/effects-of-acoustical-ceiling-panel-type-vertical-sound-isolation/