Understanding anchoring

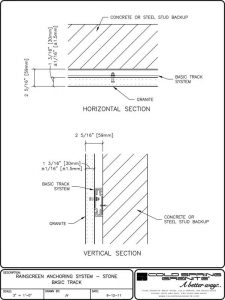

When specifying stone for a rainscreen system, it is important to understand which anchoring systems work best with the building’s design. In a traditional cladding system for stone, anchors connect each cladding piece, and a 23.5 to

50.8 mm (1 to 2 in.) air gap lies between the cladding and the building (Figure 1).

When moisture builds up in the air gap, it is pulled down by gravity to the base course of the building, where channels weep the moisture toward the outside.

Rainscreen systems keep buildings moisture-free with their open joints, creating a breathing, exterior skin. Air transfers back and forth, eliminating moisture buildup or condensation between the cladding and the building.

One of the primary design concerns with anchors for a rainscreen system is keeping them unexposed. To provide the seamless appearance of unexposed anchors with the strength required to securely hold granite in place, the two most common hanging methods include a track-type system and a rebated kerf design.

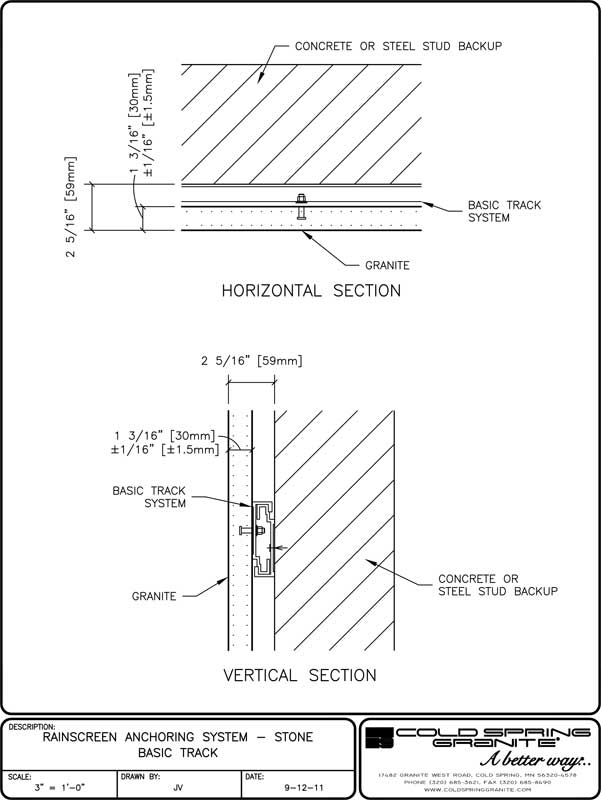

The track-type system is perhaps the most widely used way of securing stone to a rainscreen system. A track system combines wall anchors to support kerf-cut thin stone and works as a clip configuration, allowing stone to be attached to an aluminum or stainless-steel rail with a Type 31 anchor (Figure 2).

Functioning like a tension anchor, the anchor in a track system remains hidden behind the stone and does not sit in the kerf at the edge of the piece. The stone fabricator creates slots in the back of the stone pieces for the anchors to fit into. This allows joints to remain open and air to be transferred without visible anchors.

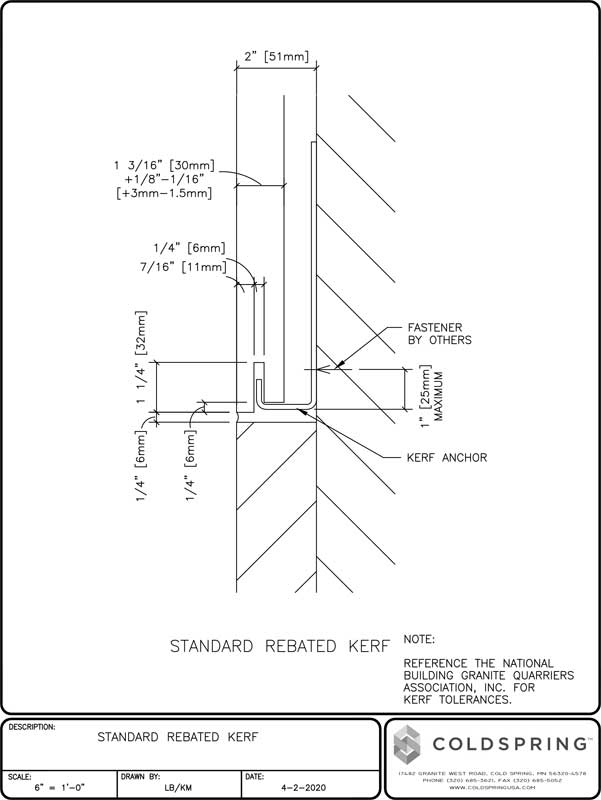

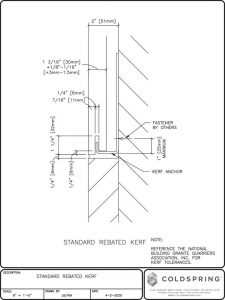

The second most common method of rainscreen anchoring is a rebated kerf design. For this method, an L-shaped cut is made in the edge of each stone piece to conceal the anchor (Figure 3).