Employing granite and rainscreens for upscale finishes

by arslan_ahmed | May 5, 2023 11:40 am

[1]

[1]By Jason Kron

While open joint or rainscreen cladding systems have become an industry standard, many design teams overlook the opportunity of incorporating natural stone into the plan. These open joint systems gained popularity in recent years for their benefits to a building’s long-term performance, with terracotta and metal being the most common selections for cladding. However, when an upscale finish or greater design freedom is desired, granite offers the ideal solution.

Stone can provide great performance with a rainscreen design, yet design teams have many questions about, how to incorporate it. Is granite too heavy for a rainscreen system? What kind of anchoring details are required? Will the stone panels remain secure? Will the rainscreen with granite remain low maintenance for years to come?

With today’s rainscreen cladding systems designed specifically to incorporate natural stone, granite can provide a long-lasting and aesthetic option for building designs. By understanding the details of the systems, a team can confidently specify granite for a rainscreen.

Understanding anchoring

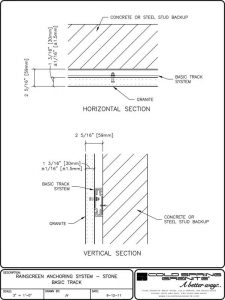

When specifying stone for a rainscreen system, it is important to understand which anchoring systems work best with the building’s design. In a traditional cladding system for stone, anchors connect each cladding piece, and a 23.5 to

50.8 mm (1 to 2 in.) air gap lies between the cladding and the building (Figure 1).

When moisture builds up in the air gap, it is pulled down by gravity to the base course of the building, where channels weep the moisture toward the outside.

Rainscreen systems keep buildings moisture-free with their open joints, creating a breathing, exterior skin. Air transfers back and forth, eliminating moisture buildup or condensation between the cladding and the building.

One of the primary design concerns with anchors for a rainscreen system is keeping them unexposed. To provide the seamless appearance of unexposed anchors with the strength required to securely hold granite in place, the two most common hanging methods include a track-type system and a rebated kerf design.

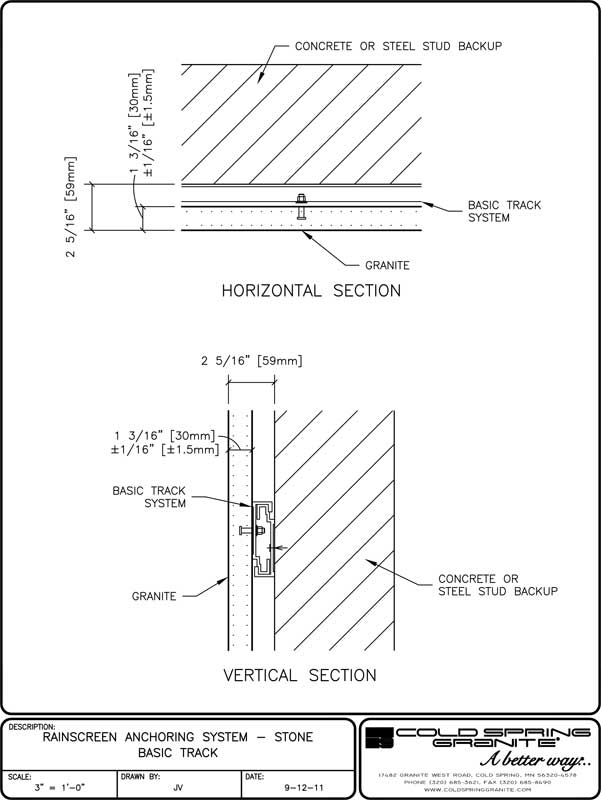

The track-type system is perhaps the most widely used way of securing stone to a rainscreen system. A track system combines wall anchors to support kerf-cut thin stone and works as a clip configuration, allowing stone to be attached to an aluminum or stainless-steel rail with a Type 31 anchor (Figure 2).

Functioning like a tension anchor, the anchor in a track system remains hidden behind the stone and does not sit in the kerf at the edge of the piece. The stone fabricator creates slots in the back of the stone pieces for the anchors to fit into. This allows joints to remain open and air to be transferred without visible anchors.

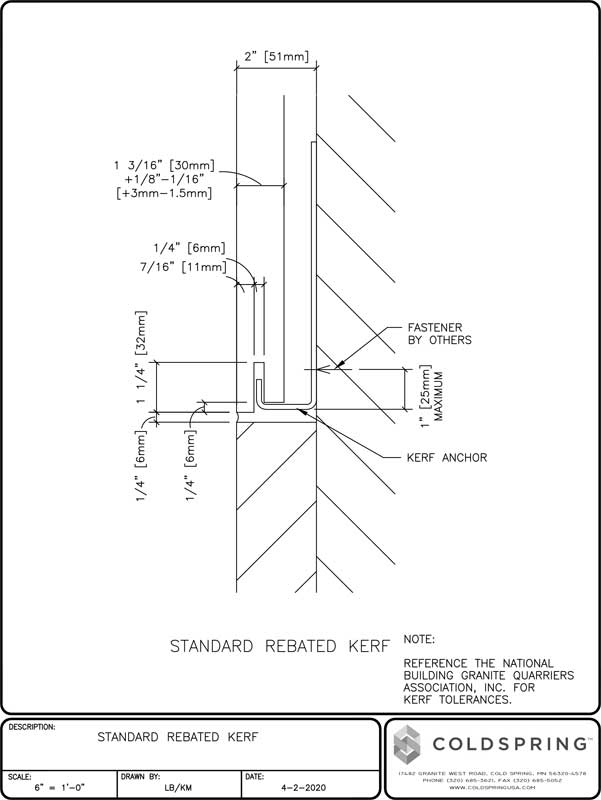

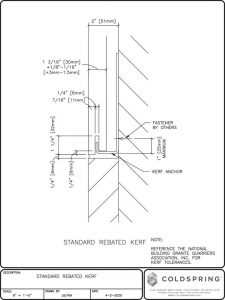

The second most common method of rainscreen anchoring is a rebated kerf design. For this method, an L-shaped cut is made in the edge of each stone piece to conceal the anchor (Figure 3).

[2]

[2]In the following case studies, different types of rainscreen systems incorporate stone for a visually appealing result with various applications.

Wayne State Biosciences Center

In the world of higher education, buildings with inspiring designs play a key role in recruitment. When recruiting researchers, the stakes are even higher. The best and brightest in the research field want a standout facility where they can collaborate, test, and develop new technologies for the future. It was Wayne State University’s mission to create this type of environment for its new biomedical research facility project in Detroit, Michigan.

The project architect desired a rainscreen cladding system for the large granite panels, which averaged 2.74 x 1.22 m (9 x 4 ft). The rainscreen protects the building’s exterior wall from rainwater by preventing it from penetrating the interior of the facility. It also lowers the risk of wall rot by leaving space for drainage and evaporation. Further, the rainscreen provides additional benefits such as ease of maintenance, thermal insulation, and enhanced interior acoustic performance.

The $93-million Integrative Biosciences Center (IBio) was the culmiation of years of planning and construction. The building encompasses 19,230 m2 (207,000 sf) and is the largest construction project in Wayne State University’s history. The facility was designed to accommodate research activities for approximately 400 researchers, staff, and more than 50 principal investigators, visiting scientists, and scholars.

Multiple exterior finishes create an eye-catching design for IBio. Approximately 836 m2 (9000 sf) of black granite finish clads the building’s southern face. Other materials, such as glass and brick, were used as well—representing a fusion of modern and traditional design.

[3]

[3]“One of the important goals was to make sure the building stood out,” says Anne-Lee Vandenbussche, director of planning and management at Wayne State University. “It’s the first WSU building you see driving down Woodward toward downtown Detroit.”

Both modern and traditional design elements were important for the design, as the building itself is a juxtaposition of existing and new construction. Covering one square block, the facility includes the repurposed space from a former historic 1927 auto dealership, designed by renowned industrial architect Albert Kahn. The historic building was expanded with 7246 m2 (78,000 sf) of new construction.

“Granite as a material selection provides a nice connection between the existing and the new,” says Vandenbussche. “It’s considered a timeless product. Granite gives the appearance of a building with 50 to 80 years behind it, but it looks modern, too.”

Granite’s inherent durability is a good choice for universities, where ease of maintenance and the ability to stand the test of time are two important considerations. The granite’s durability was further enhanced by its incorporation into a rainscreen cladding system.

Achieving success with the rainscreen required close coordination between the stone fabricator and supplier. They designed the track-type hanging system needed to support the granite panels. Ultimately, the fabricator and supplier met the project’s requirements and schedule and achieved the look the university and architect wanted. A team of contractors implemented the plan for a successful installation and completion of the rainscreen. Every team member involved, from design to installation, had to be engaged and precise to ensure the rainscreen was properly completed.

The Leadership in Energy and Environmental Design (LEED) silver building is an important project for Wayne State University, as it enables the university to participate in the National Institutes of Health (NIH) funding and initiatives. Further, the university played a key role in the economic revitalization of Midtown Detroit by redeveloping 1.11 ha (2.75 acres) of vacant real estate.

“Everyone loves this building, and we get a lot of compliments on it,” says Vandenbussche. “We’re proud to be the gateway to the university from Detroit.”

Clad with a rainscreen system to prevent moisture and freeze-thaw damage, IBio will provide a long-lasting solution for the students at Wayne State, as well as the people of Detroit.

[4]

[4]50 FIFTY

The 50 FIFTY building in Denver, Colorado, provides an example of a rainscreen cladding creating a modern aesthetic. 50 FIFTY is a 12-story tower of Class AAA office space—a designation it earns by its superior materials and finishes.

The 17,187 m2 (185,000 sf) building consists of five full floors of parking, six floors of open office, and one double-height lobby. The building’s elevated office floors offer excellent views of the surrounding mountains. The building has become a visible landmark for travelers on the adjacent Interstate 25 (I-25). Building amenities include co-working spaces, a fitness facility, a roof deck, and a lobby with accommodation for both a financial institution and a café.

Befitting the building’s prominent location, design excellence was a priority, and handpicked granite was one of the metrics for meeting quality and performance standards. In auto dealership, approximately 3,437 m2 (37,000 sf) of granite was selected for the project. White stone was used for the building’s rainscreen cladding. The stone features a consistent appearance and its light color fits well with the project inspiration of nautical themes. The thermal finish was then added to deliver the slightly smooth texture. A thermal finish is applied using a very hot torch. The high thermal mass of granite allows extreme temperature variations between minerals when exposed to short bursts of intense heat. The rapid movement of molecules near the burned surface causes the stone to flake and shell, leaving an aesthetically pleasing, natural looking, textured finish.

The design elements were based on the owner’s passion for sailing. The white stone is “representative of the whitewater break a sailing vessel makes as it cuts through the ocean,” says Robin Ault, director of design and principal at Clutch Design Studio.

Coldspring, a natural stone fabricator and manufacturer in Cold Spring, Minnesota, assisted with detailing and sampling various finishes of granite colors during the selection process. Members of the teams visited Coldspring’s quarry, where they learned about plant processes and viewed the exact stone which would be used on the building later on.

The architects worked with a curtain-wall subcontractor to develop a clip system for the rainscreen and integrated it with their standard curtainwall system. Black stone was also installed in the tower as a wall base to accentuate the building’s lightwells.

[5]

[5]Black stone with a diamond finish was used for wall cladding, copings, and stair treads.

“We didn’t want a monolithic feel for the site detailing what you might find at a courthouse or monument. Rather, we opted to detail the walls and steps in a way that would bring together multiple materials, such as stainless-steel risers with granite treads, and granite wall veneers combined with stainless steel and Ipe wood seat decking. All were intended to capture that yacht level of craftsmanship,” says Craig Vickers, principal, Civitas Inc.

The result was a finely crafted office building for businesses in downtown Denver.

Temple University Library

Located in Philadelphia at Temple University, Charles Library is one of the country’s most modern and significant new library constructions in recent history. Its design demonstrates the creative possibilities with granite and rainscreen systems and fulfills the architect’s intent to spur imagination and inspire excellence.

[6]

[6]Key to the building’s striking design is more than 3,437 m2 (37,000 sf) of black granite, specified for exterior cladding, windowsills, soffits, coping, and a green roof wall facade.

Vertical sections of the granite in a split-face finish clad the library’s solid base and coordinate with the existing landscape of the campus. More than 2,787 m2 (30,000 sf) of granite pieces—each featuring rustications or reveals—were successfully produced with manufacturing skill and quality.

The stone’s installation on a sealant-less, caulk-less rainscreen system leaves space for water drainage and evaporation, preventing water from penetrating the facility’s interior while lowering the risk of wall rot.

[7]

[7]Each long, slender granite piece for the building’s cladding measures approximately 406.4 mm (6 in.) wide, 1.22 m (4 ft) long, and 57.2 m (2.25 in.) deep, presenting a challenging installation for the contractor. Since the stones are small, they rely on two points of attachment rather than the typical four.

The team laid out the rainscreen’s extruded, anodized aluminum grid system at their shop before delivering it to the site. Each aluminum rail measures 9.1 m (30 ft) long.

Black granite also provides a key design element for the new library project’s green roof, where it adorns the facade and coping. The dimensional, 0.61 x 0.61 m (2 x 2 ft) granite blocks provided challenging rigging, logistics, and installation at the building’s parapet.

This project, in particular, had a challenging installation due to its small piece size; it had two anchor points instead of the typical four. However, with the skilled and well-coordinated team, there was success at every stage.

Today, Charles Library is a centerpiece of Temple University and the city of Philadelphia, where its inspiring design promotes learning, innovation, and community.

Collaboration is key

Key to successful projects is early collaboration among all project team members. When stone is considered for a rainscreen cladding system, the stone supplier should be contacted as part of the conception phase. Working closely with suppliers from the onset of the project will ensure success in realizing the design goals; and the beauty and permanence of stone, such as granite, can be successfully incorporated into the rainscreen system as well.

Author

Author

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/charles-001.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/charles-003.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/charles-004.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/5050_2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/5050_3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/Wayne-State-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/05/Wayne-State-3.jpg

Source URL: https://www.constructionspecifier.com/employing-granite-and-rainscreens-for-upscale-finishes/