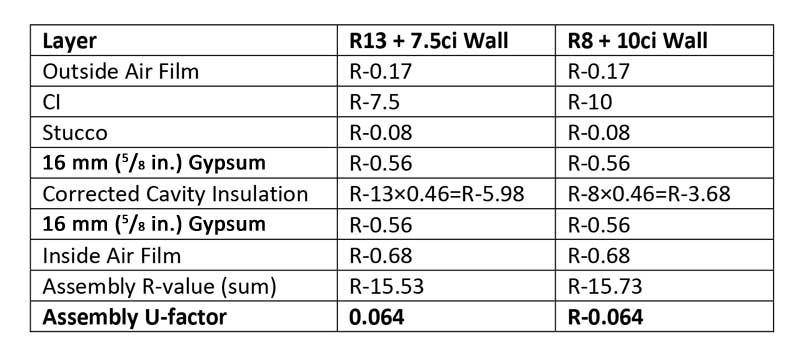

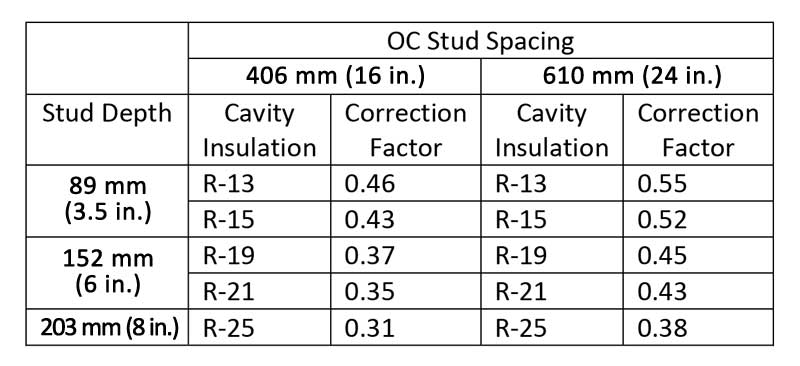

Essentially, the code treats the cavity/stud layer of the wall assembly as a single layer with its own R-value, and provides a correction factor to compute the appropriate R-value. For example, in climate zone six, IECC commercial provisions require a wall u-factor of 0.064 or less. The correction factor for climate zone six with steel studs at 406 mm (16 in.) o.c. is 0.46. Another way of saying this is a layer of cavity insulation contributes only 46 percent of the listed R-value to the overall wall performance. Consider the two qualifying walls in Figure 6. The advantage of ci over cavity insulation is more obvious in steel-framed walls. In this comparison, adding just R-2.5 of ci more than makes up for removing cavity insulation worth R-5. With deeper 152- and 203-mm (6- and 8-in.) steel studs, the disparity only grows. The full list of correction factors is shown in Figure 7.

Though there are many choices when it comes to ci products, polyisocyanurate (or simply polyiso) stands out for its high R-value per inch of 6 (or more, when layers 76 mm (3 in.) or thicker are used). Polyiso ci is available in thicknesses from 6.35 to 114 mm (¼ to 4.5 in.) or more. For the R-7.5 ci requirement, just over an inch of polyiso would be needed. An additional incentive is most polyiso is sold with a foil facer on one or both sides. This is important as polyiso ci can serve as an air- and water-resistive barrier, saving labor and materials costs, if the facer is properly taped, sealed, and integrated with flashing at penetrations. Additionally, polyiso is manufactured without the use of global-warming-causing blowing agents, making it an attractive choice. Thus a wall using polyiso ci can achieve the code-required, minimum R-value with thinner materials than other ci products, thereby providing more saleable floor space.

If one would like to further explore proper wall design for thermal behavior, visit the wall calculator developed by the Applied Building Technology Group. (Visit www.appliedbuildingtech.com/fsc/calculator for the wall calculator.) This tool uses the approach the authors have outlined to compute the effective R-value and U-factor of a wood-framed wall, and depending on climate zone, determines whether the wall is code-compliant. Additionally, the calculator handles moisture code compliance, another tricky area in design. A version of the calculator for steel walls taking the same approach is in the works.

Timothy Ahrenholz is a special projects engineer with the Applied Building Technology Group. In this role, he develops design solutions for foam sheathing products. Ahrenholz has been involved with standards development and code change proposals for the I-codes and the National Building Code of Canada (NBC). He holds a master’s degree in civil engineering with a structural focus from the University of Illinois, and bachelor’s degrees in physics and mathematics from Covenant College. He can be reached at tahrenholz@qualtim.com.