Photo © Jeff Amram Photography; Photo courtesy Wausau Window and Wall Systems

Laminated glass

Laminated glass is often a cost-effective option for improving acoustic performance. Using laminated glass minimizes ‘coincidence’—a resonant frequency exhibited by rigidly supported lites of glass, usually occurring within the frequency range tested in ASTM E90. Coincidence can be the controlling factor for STC ratings. (Resonance appears in the test results as ‘dips’ in the TL curve.)

Resonances can be seen by increased sound transmission at a specific frequency or frequency range. Resonant frequency sometimes can be shifted out of the audible range by changing the size, thickness, and aspect ratio of glass lites. The location of laminated lites (interior or exterior) within the assembly makes no significant difference in acoustic performance, nor does heat-strengthening or tempering.

Temperature also can affect the sound transmission loss of laminated glass panels. Windows and/or curtain wall systems containing laminated glass perform better in warm environments than cold ones, since the interlayer’s damping characteristics improve at higher temperatures. American Architectural Manufacturers Association (AAMA) technical information report (TIR) A1-15, Sound Control for Fenestration Products, has shown the STC and OITC ratings can change by up to five and three dBA respectively, over a glass temperature range of 15 to 32 C (60 to 90 F).

Assemblies with more than one laminated lite may introduce unexpected visual distortion, coating limitations, or other design issues. It is important to always check with glass fabricators and review samples before specifying ‘double-laminated glass.’ Additionally, thin laminated glass can be subject to rather restrictive size limits in fabrication.

Laminated glass also offers significant benefits in ultraviolet (UV) light protection, making it particularly useful in environments with furnishings or carpeting that can fade, or in rooms with sun-vulnerable items, such as a museum gallery. When properly glazed, it can offer improved impact resistance over annealed glass. However, using laminated glass does little to improve thermal performance and can limit the choice of colors, coatings, and heat treatment options available to the specifier.

Increased air space

An alternative to laminated glass involves increasing the air space of insulating glass units (IGUs) with non-standard spacers or interior access doors. In general, adding another layer of glass at the expense of air space does not help much; a 38-mm (1 ½-in.) triple IGU performs similarly to a 38-mm double IGU. Air and argon in the space of an IGU perform essentially the same. The practical limit on sealed IG air space width is 19 mm (3/4 in.) to 25 mm (1 in) depending on makeup.

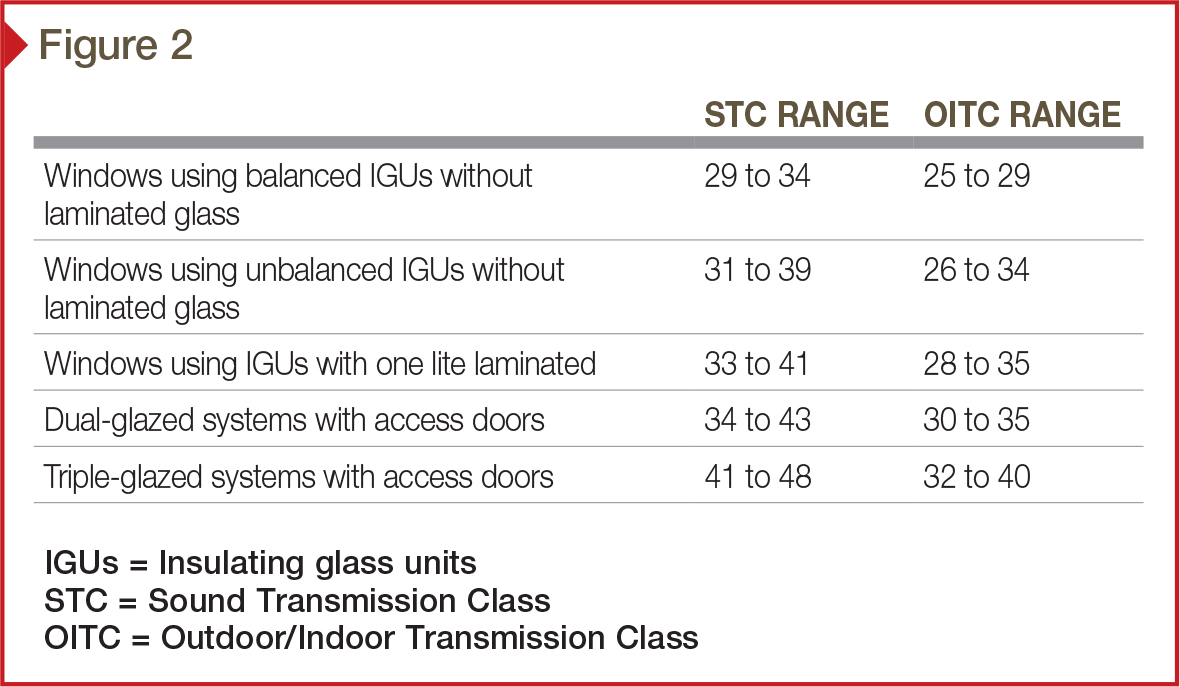

Having incremental changes in air space typically offer only marginal improvement in acoustic performance. In recent Element Materials Technology side-by-side tests of IGUs employing the same unequal glass thickness at the interior and exterior lite, increasing the air space from 13 to 25 mm (1/2 to 1 in.) improved STC by 1 dBA, with no change in reported OITC (Figure 2). As noted in AAMA TIR A1-15, mass-air-mass resonance across the air space of an insulating or dual-glazed assembly is also possible, usually evident at low frequency.

Larger non-hermetically sealed air spaces typically improve both acoustic and thermal performance, as well as solar heat gain coefficient (SHGC), but can introduce the need for periodic cleaning. Interior access doors can be fitted with integral between-glass venetian blinds, which are suitable for healthcare and educational facilities. Unlike their interior, free-hanging counterparts, integral blinds arc protected from damage and dirt, and usually are fitted with occupant tilt-control and custodial raise/lower. This prevents the checkerboard appearance of blinds hanging at all levels of the building.

The window designer must pay special attention to all expected seasonal temperature and humidity conditions within these air spaces to minimize the potential for between-glass condensation. Integral blinds often require heat-strengthening of interior/exterior glass to prevent thermal stress breakage. Dual glazing in not recommended for cold-climate hospitals; one should use exterior IGU with an interior single-glazed access door instead.

When existing windows are weathertight, and ventilation is unnecessary, interior accessory windows can improve sound, energy, air and light control economically, and with a minimum of occupant disruption.