by Brian Fiegen

As many designers can attest, selecting the most appropriate HVAC system involves more than an off-the-shelf purchase. Designing a mechanical system for maximum energy efficiency, reliability, serviceability, and sustainability—while meeting the varying usage needs of the customer—requires broad expertise and a thorough understanding of key considerations in system design. Having the right team and leveraging design resources and tools, including utilizing HVAC manufacturer applications experts, are important elements in selecting a system suited for customer needs and application requirements.

Many details in the design and operation of the system can have an impact on its performance. While the upfront cost frequently dominates the decision-making process for customers in designing an HVAC system, other important considerations should include ongoing efficiency savings, lower lifetime maintenance costs, service requirements, and performance.

Other factors influencing the design may include hours of system operation, ambient conditions, utility rate structure, and mission-critical reliability requirements. Understanding how these factors impact system requirements and design is critical to the process.

Resources to aid in the decision process

Energy modeling and building simulation tools that compare the performance of system options are among the most powerful instruments engineers have to help make system design decisions. For example, advanced and comprehensive load design and energy analysis software can provide design-sizing and building-load profile information such as peak and hourly loads to begin the equipment-sizing decision-making process.

Analyzing a building load profile provides insight into the preferred system configuration options for consideration. Creative system options such as asymmetrical system design or thermal storage may become potential options. Once the selected options have been identified, building simulation can begin.

The output from this work includes information such as energy consumption and demand by system element, which allows the designer to know what to expect with each building design variation and the implications it will have on building performance. With this additional insight, derivatives of the selected options can be considered and modeled.

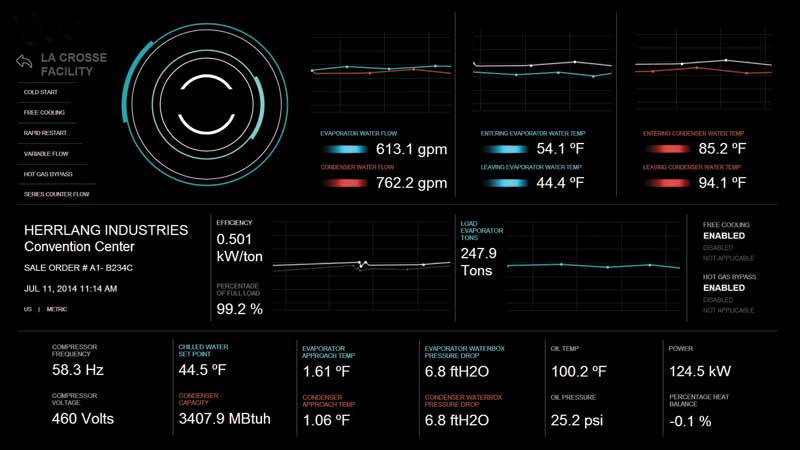

Sometimes this work is too lengthy and costly, particularly early in the design process when scoping and concept work is the goal. In these situations, an engineer can utilize simpler or narrower-focused tools. One example is a chiller plant analyzer. This tool allows the engineer to focus on the chiller plant without the distractions of the detailed building elements.

Preferred system configurations can be quickly assessed for concept selection purposes. These selected options can then be carried forward to the full building simulation work appropriate for later in the design process.

Finally, there are times when specific equipment decisions need to be made quickly and objectively. In these situations, online manufacturer-agnostic tools help engineers and building owners quickly and accurately estimate chiller energy usage and costs. The predictive software value and economic payback calculated reflects the chiller plant’s design, installation location, and building purpose while avoiding the more in-depth and costly process of a full building energy simulation model.

There is every reason to turn to objective evaluation methods to make sound system solution decisions. Valuable tools exist for multiple points in the design process and for various levels of detail necessary to meet the needs of most jobs.