Ensuring safe walking surfaces with exposed concrete

by Katie Daniel | January 15, 2018 2:35 pm

[1]

[1]By Chris Bennett, iSCS, CDT

In the world of architectural exposed concrete floors, few considerations are more important than coefficient of friction (COF). French-American architect Paul Philippe Cret (1876-1945) once asked, “Of the many doorways one passes, most are well enough built—but which ones are worth a second look?” His implication was not to forget beauty in the pursuit of function. However, the concrete floor industry has suffered from an almost antithetical approach in which the floors are beautiful, but answers to questions surrounding their prime function—a safe walking surface—have been harder to define.

Specifier and architect George Hauner (Grimshaw Architects) believes “the average client does not understand how to apply COF to floor finishes.” Competing narratives from manufacturers and trade organizations have also contributed to the complexity of attempting to quantify ‘polished’ concrete flooring. Slip and fall cases are expected to rise as the baby boomer generation (more than 46 million people) become the elders in the society. One needs to do better to take care of the people using the floors one creates. The first step in building a safe floor is knowing how to describe and identify benchmarks for safety in the construction documents.

With the amount of legal and medical concerns facing the owner-group, demand for building and maintaining safe spaces has never been more important. According to architect Winnie Law, senior associate at Gensler, “A safe environment is one of the most fundamental design criteria in creating useful spaces and COF is always part of that equation.”

Cost of slips and falls

The reasons why design and construction professionals place such an emphasis on slip and fall safety are numerous and speak for themselves. According to Occupational Safety and Health Administration (OSHA), slips, trips, and falls account for 15 percent of all accidental deaths, second only to auto accidents. Falls account for more than 8 million hospital emergency room visits, representing the leading cause of visits. (This is according to a study by National Floor Safety Institute [NFSI].) An ITT-Hartford Insurance Company study revealed worker compensation from falls account for 16 percent of all claims and is one of the primary causes of those lost work periods exceeding a 31-day timeframe. The costs in litigation, settlements, and associated medical costs are also staggering. According to the 2003 edition of National Safety Council’s (NSC’s) Injury Facts, annual compensation and medical costs that are associated with employee slip/fall accidents reach approximately $70 billion. Nearly 85 percent of worker’s compensation claims are attributed to employees slipping on slick floors. (For more information, read the fifth edition of the Industrial Safety and Occupational Health Markets, published by IBISWorld in November 2016. Visit www.ibisworld.com/industry-trends/specialized-market-research-reports/life-sciences/wellness-services/occupational-health-workplace-safety-services.html[2].) Compounding the problem are fraudulent cases facility owners and insurance groups face on a daily basis. The National Insurance Crime Bureau (NICB) found a 57 percent increase in and fall fraud between 2008 and 2010 with the average liability award for injury, according to National Floor Safety Institute (NFSI), running from $60,000 to $100,000 per claim. These are resources not being used on people who may truly need help because owners are forced to allocate resources to this issue. This places extra pressure on the project team to create exposed concrete floors with quantifiable finishes.

[3]

[3]Floor safety tests

Businesses can protect themselves from some level of fraud with appropriate insurance and one can take care of medical costs when truly needed, but these steps only treat symptoms. These do not address how to test for floor safety or how to create a safe concrete floor finish in the first place. So how does one test properly for COF? What items can be included in the construction documents to ensure proper installation and testing take place? Some of the best ways to measure initial COF for exposed concrete surfaces are with ANSI/NFSI B101.3, Wet Dynamic COF Standard, or the older ASTM E303-93 Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester.

The scope of the ANSI/NFSI B101.3 includes test methods and procedures used for field-testing to measure the wet dynamic coefficient of friction (WDCOF). It is based on the European standard DIN 51131, Testing of Floor Coverings–Determination of the Anti-slip Property–Method For Measurement of the Sliding Friction Coefficient, and therefore, is easy to use in North America as well as overseas. The British pendulum method is perhaps the most widely used globally and has a long history of use and supporting data[4].

Architect and specifier Vivian E. Volz, RA, CSI, CCS, AIA, LEED AP (VVAS), prefers the ANSI B101.3 test.

“When it comes to protecting the people that use our spaces, I am a lot more confident in a dynamic test like B101.3, because slips and falls happen when people are moving, not when they’re standing still. There is no reason to specify a static test anymore: it proves nothing about the safety or accessibility of a floor. DCOF testing is what we should require to get floors right,” she states.

[5]

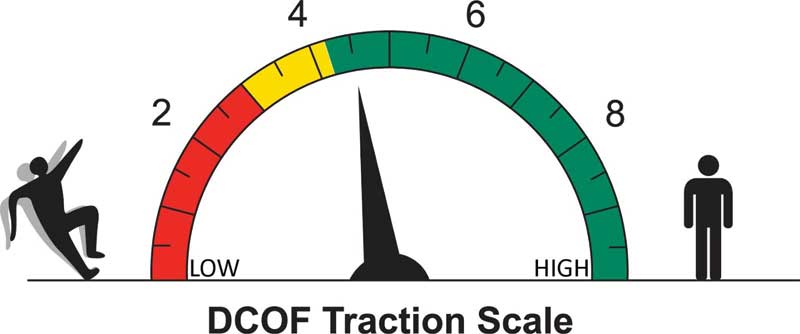

[5]According to NFSI, high-traction floors have been clinically proven to reduce up to 90 percent of slip and fall claims. ANSI/NFSI B101.3 grades a walking surface under the assumption the person is moving on a contaminated surface (e.g. water and grease). ANSI/NFSI B101.3 was also specifically created with refined, polished concrete floors in mind.

Unlike other testing methods in which small, prefabricated material samples are sent to a laboratory to be tested and then conclusions are drawn on how a concrete floor (possibly yet to be poured) might perform in regards to safety, both NFSI and the British pendulum test include guidelines specifically to measure the actual floor. Field testing for floor safety consists of using an important piece of portable technology—a walkway slip-resistance tester known as tribometer or the British pendulum, which measure coefficient of friction. Acceptable tribometers have gone through a battery of testing to get NFSI approval to ensure calibration, repair, maintenance, and field performance verification is possible to ensure device reliability. According to NFSI, any tribometer manufacturer should also provide validation and calibration reports as per the ASTM F2509-2011, Standard Practice for Validation and Calibration of Walkway Tribometer using Reference Surfaces. These types of tribometers are used in testing to discover whether a floor has in fact achieved acceptable DCOF as per ANSI/NFSI B101.3 The test itself consists of placing the tribometer on the ground and allowing the device to take multiple measurements in all cardinal directions to take a measure of the floors’ COF. Water and surfactants can be used in the test to lower the surface tension between the floor and the instrument contact point to approximate a foot coming in contact with a contaminated or wet surface.

Average roughness measurements

Architectural exposed concrete floors like polished finishes are different from tile and other floors because they are fabricated and installed onsite. The final floor’s safety depends on how one processes and refines the concrete surface while the floor is being created. How can the process of floor safety be quantified before testing it with a tribometer? Many design professionals may already be familiar with profilometer, a measurement device used in determining refinement benchmarks in concrete floor finishes. This portable tool may also aid in achieving consistent COF.

A profilometer measures the micro surface of the concrete floor to determine its level of refinement and quantify the surface micro texture. Average roughness (Ra) measurements, taken in either microinches (µin) or micrometers (µm) describe the surface profile of the concrete. American Society of Mechanical Engineers (ASME) B46.1, Surface Texture (Surface Roughness, Waviness, and Lay), describes Ra as the arithmetic average of the absolute values of the profile height deviations from the mean line, recorded within the boundaries of the evaluation length. It is a set of separate measurements of peaks and valleys on a surface. These mathematical descriptions of the floor surface correlate directly with COF. Using prescribed methods, one can measure Ra during the process of installation and see its relationship to COF.

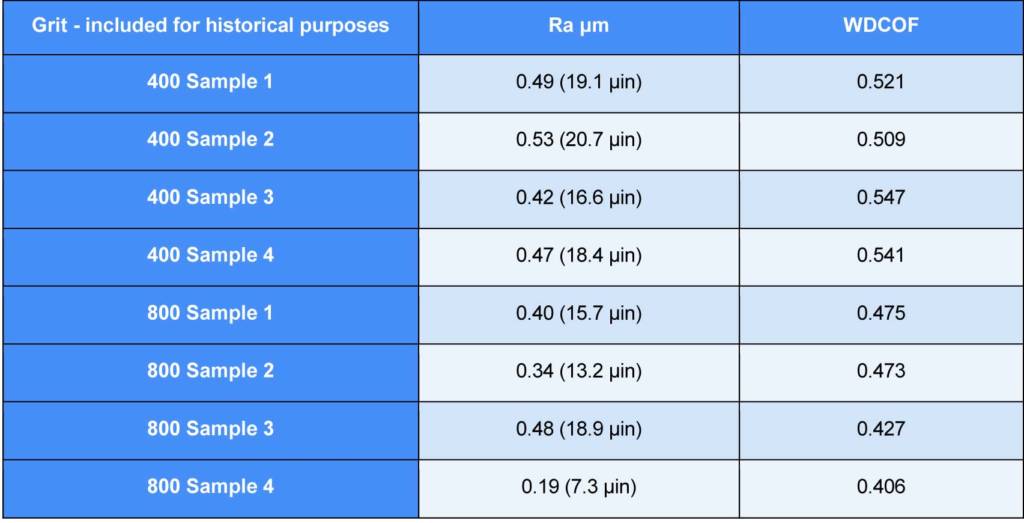

[6]

[6]Image courtesy Chris Bennett

In Figure 1, one can see the average Ra value of the floor ‘400 grit’ is 0.47 µm (18.7 µin). Measurements taken by an approved NFSI tribometer on the same space show the average WDCOF is 0.53. At ‘800 grit,’ the averages were 0.35 µm (13.78 µin) and an average WDCOF reading of 0.45. It is a simple correlation using NFSI B101.3 and surface profile measurements to take two different, but related measurements of a surface. Just like in Figure 1, one can specify an Ra value of 0.41 µm (16 µin), and know that even when wet or contaminated, the floor should be able to correlate to COF readings. Using Ra as a guideline onsite, a constructor can adjust floor refinements if they believe COF may not be met prior to handing over a completed floor to the client without need for more expensive testing or delays. Ra may need to be adjusted on inclined surfaces to ensure high traction readings similar to flat surfaces.

Maintenance of walking surfaces is the other half of slip resistance and should also be a part of the specification. This Ra number is of value to the owner while maintaining the floors as well—they are able to select maintenance pads and materials that retain the initial Ra value and preserve not only the floor aesthetic but also its COF throughout the facility’s lifecycle. In short, Paul Philippe Cret would be inclined to agree both form and function have been achieved.

[7]

[7]Photos courtesy Chris Bennett

“Due to the increased popularity of polished/exposed concrete surfaces as its own floor finish, more people, including owners and facility directors, are much more conscientious about coefficient of friction requirements,” says Eric Lussier, CSI, CDT, co-founder of the Let’s Fix Construction education series. (Visit www.letsfixconstruction.com[8] for more information on the series.) “From my experience, architects are seeking direction from industry professionals who can point them to proper standards and usage to meet these needs.” There are other standards from manufacturer organizations competitive to the concrete floor industry (e.g. Tile Council of North America’s [TCNA’s] ANSI A137.1, Tile Slip Test) that do not fall within the safety benchmarks of NFSI B101.3. However, many manufacturer trade associations from various flooring industries have promoted ANSI A137.1 and its derivatives as their preferred standard.

Russell Kendsior of NFSI notes, “The TCNA standard excludes polished concrete in its scope and only applies to un-installed ceramic tile. ANSI/NFSI B101.3 specifically states the standard applies to polished concrete.” NFSI is also the designated ANSI standard-developer for slip, trip, and fall prevention.

[9]

[9]Image courtesy National Floor Safety Institute

Conclusion

In the pursuit of beauty and COF performance, specifiers can take simple steps to ensure safe exposed concrete floor finishes. Indicating ANSI/NFSI B101.3 or ASTM E303-93 as the COF reference standard in concrete floor finish specifications sets the bar for how the client’s floor will be measured to ensure consistent COF even when the floor is wet or contaminated. Requiring quality assurance guidelines in your specifications will help ensure the final performance qualities of your exposed concrete floor.

Tony Heimkes, Hines-Property manager at Galleria Shopping Center (Edina, Minnesota), states, “Our commitment to safety is first priority for our guests, merchants, and visitors. Flooring concepts achieving NFSI B101.3 benchmarks give us the reassurance this commitment will be upheld.”

Chris Bennett, iSCS, CDT, is a critical voice in the development of sustainable concrete solutions to replace expensive, outdated methods. His firm, Bennett Build, leads project teams in lowering the economic and environmental costs of designing and implementing stronger concrete systems. He can be reached at www.BennettBuild.us[10].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Panorama-e1516043309453.jpg

- www.ibisworld.com/industry-trends/specialized-market-research-reports/life-sciences/wellness-services/occupational-health-workplace-safety-services.html: http://www.ibisworld.com/industry-trends/specialized-market-research-reports/life-sciences/wellness-services/occupational-health-workplace-safety-services.html

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Galleria.jpg

- data: https://www.astm.org/e0303-93r18.html

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Tribometer.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Figure-1-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Edina.jpg

- www.letsfixconstruction.com: http://www.letsfixconstruction.com

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Traction.jpg

- www.BennettBuild.us: http://www.bennettbuild.us/

Source URL: https://www.constructionspecifier.com/ensuring-safe-walking-surfaces-exposed-concrete/