by Paul Bertram, FCSI, CDT, LEED AP, GGP

Buildings designed with energy efficiency in mind are becoming the norm. In fact, according to a 2013 McGraw-Hill study, “firms are shifting their business toward green building, with 51 percent of respondents planning more than 60 percent of their work to be green by 2015.”1 As a result, design/construction professionals are constantly seeking methods to verify the ‘greenness’ of buildings.

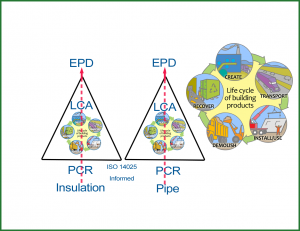

One increasingly popular strategy to confirm energy efficiency is to use an environmental product declaration (EPD) as a way to help decision-makers evaluate and specify products with a low environmental footprint. EPDs are based on industry product category rules (PCRs), themselves developed to use environmental lifecycle assessment (LCA) data based on International Organization for Standardization (ISO) 14040, Environmental Management–Lifecycle Assessment: Principles and Framework.

In an article that appeared in the March 2013 issue of The Construction Specifier, Julie Rapoport, PhD, LEED AP, described the EPD as:

a document created by the manufacturer to show results of a lifecycle assessment. It is verified by an expert and approved by a program operator, such as UL Environment (ULE) or the aforementioned MTS [the Institute for the Market Transformation to Sustainability]. …EPDs can have requirements for how often they must be renewed. For example, SMaRT EPDs used by this author’s firm must be renewed every three years. During the renewal process, aspects like energy input can be revisited and updated.

In short, EPDs report a summary of the environmental impacts of a product across its entire lifecycle, including impacts from the manufacturing process and upstream supplied materials. To reflect a product’s overall environmental impact, an EPD takes into account the energy use and environmental impact of all phases of a product’s life—from raw material extraction to end-of-life.

The EPD also provides detailed and verified data for multiple attributes of a given product such as durability, maintenance costs, use phase performance, demolition, and end-of-life disposition. This data allows construction professionals to learn about a product based on its cradle-to-gate/grave impacts.

However, having an EPD alone does not make a product ‘green;’ it is also not a statement of environmental superiority. Rather, an EPD provides documentation of lifecycle and other related data for a given product system. This allows the entire building team to compare similar products and/or additional EPDs of a similar product system, gaining a better understanding of trade-offs and product system improvement.

EPDs and better buildings

As EPDs are used more frequently to understand the environmental impacts of building products, their affect on buildings’ overall environmental contribution becomes clearer. An EPD displays statistics about environmental impacts, providing construction professionals with third-party verified reporting information about products they would like to use, allowing them to make more informed decisions. With more products being verified through the EPD process, specifiers, architects, and building owners are better able to understand the environmental footprint of their buildings by reviewing other EPDs or performing more detailed product analyses according to ISO 14044 standards.

Increasingly, this means EPDs serve a vital role. The higher the quality of information a specifier or architect has when drafting a building design, the more material-efficient and less environmentally impactful a building can be. In fact, the U.S. Environmental Protection Agency (EPA) has acknowledged EPDs can help document the impacts of building materials. As a result, many industry professionals are calling for the incorporation of EPDs into green building codes. In response, various green building system organizations have incorporated, or are considering, EPDs as an option in their standards and recommendations.

How to use EPDs

For practical purposes, EPDs can be divided into two categories: product-specific and industry-wide.

Product-specific EPDs are completed for particular products. This type of EPD is valuable if clients or building owners want to use specific materials in a building project. Typically, the company or corporation producing the product funds the development of a product-specific EPD.

The industry-wide EPDs are based on an aggregated average of similar materials or products within a sector. For example, the Metal Construction Association (MCA) issued three industry-wide EPDs for insulated metal panels (IMPs), metal composite material (MCM) panels, and roll-formed steel panels for roofs and walls.2 This category of EPD is especially valuable to specifiers interested in choosing a generic category of product—such as sprayed polyurethane foam (SPF)—rather than requiring the use of proprietary materials.

Regardless of the type, EPDs are developed under ISO 14025, Environmental Labels and Declarations–Type III Environmental Declarations: Principles and Procedures, which define the process of developing an EPD, including the crafting of product category rules and verification requirements by program operators.

Program operators have working knowledge of the elements required by an EPD, such as:

- existing product category rules;

- how to produce a scientifically verifiable lifecycle analysis; and

- which quantitative measurements show a product’s environmental impact.

As this relatively new field is developing, additional international guidelines are being created for program operators.

In terms of formatting EPDs, some use a simplified document known as an EPD Transparency Brief. These two-page summaries boil down the essential data into an easily understandable, standardized form. The data reported on this form includes:

- the product’s ingredients or components (including a special note of any recycled content);

- cradle-to-grave environmental impacts;

- how much water and energy is required;

- end-of-life requirements; and

- any special certifications.

Many program operators maintain databases of published EPDs, and there are tools available to assist with the production of an EPD. Some examples include:

- Swedish Environmental Management Council’s searchable database;

- Athena EcoCalculator, maintained by the Athena Sustainable Materials Institute, which allows construction professionals to calculate a quick snapshot of a building’s footprint using pre-defined, pre-assessed building assemblies;

- U.S. National Renewable Energy Laboratory’s (NREL’s) lifecycle inventory database that assists with lifecycle analyses; and

- ULE’s free, searchable database of EPDs produced by the company.

In some cases, EPD information can be found in the product data sheet or marketing materials from the company producing the material.

EPDs and code officials

As EPDs are used more frequently to quantify environmental information about building products and subsequently help design professionals understand the environmental footprint of buildings, it may make sense to consider incorporating them into building codes and standards.

Currently, EPDs are accepted under the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) v4 standard; ASTM International also recently created its own EPD verification program. Officials with the International Code Council (ICC) could also soon be looking to see whether EPD-certified products have been specified for use in both residential and commercial building projects.

In fact, members of the ICC will be considering EPDs as an alternative compliance pathway in the 2015 version of the International Green Construction Code (IgCC). This code establishes a baseline of ‘green’ requirements for buildings, and is up for a vote in October. If incorporated into the 2015 IgCC, EPDs will give code officials, building professionals, and specifiers an additional, optional compliance pathway for materials and resources, improving the process for declaring a building ‘green.’

Notes

1 For more, see the 2013 World Green Building Trends SmartMarket Report at construction.com/about-us/press/world-green-building-trends-smartmarket-report.asp. (back to article)

2 Visit www.metalconstruction.org/index.php/education/environmental-product-declarations.(back to article)

Paul Bertram, FCSI, CDT, LEED AP, GGP, is director of environment, sustainability, and government affairs for Kingspan Insulated Panels. He is a noted expert in the area of environmental product declarations. At Kingspan, Bertram is responsible for the company’s environmental and energy-efficiency strategies, supports the company’s high-performance building initiatives, and coordinates lifecycle analysis and sustainability reporting efforts. He is also a CSI Fellow and past-president. Bertram can be contacted by e-mail at paul.bertram@kingspan.com.

Paul Bertram, FCSI, CDT, LEED AP, GGP, is director of environment, sustainability, and government affairs for Kingspan Insulated Panels. He is a noted expert in the area of environmental product declarations. At Kingspan, Bertram is responsible for the company’s environmental and energy-efficiency strategies, supports the company’s high-performance building initiatives, and coordinates lifecycle analysis and sustainability reporting efforts. He is also a CSI Fellow and past-president. Bertram can be contacted by e-mail at paul.bertram@kingspan.com.

Good work Paul. Cheers