Providing adequate rainwater management and control for air, vapor, and heat flow through the building enclosure is critical to long-term performance and durability. In contemporary wall assemblies with layered materials, the complexity of coordinating these various demands can be overwhelming.

Historical developments of building enclosure design and construction evolved through the centuries from monolithic, load-bearing mass walls through transitional masonry to today’s modern building enclosure systems. Thanks to technological advances over the last several decades, emerging construction materials, methods, and techniques have led to thinner, lighter, and more complex exterior walls consisting of multiple material layers.

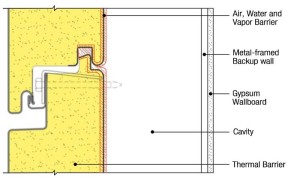

Contemporary building enclosures perform a multi-faceted role in managing what is typically referred to as ‘environmental loads.’ In addition to transferring dead and live loads, the enclosure must manage moisture in both liquid and vapor states—transported through air leakage and diffusion—as well as the flow of thermal energy. In design practice, these elements are controlled by using water, air, vapor, and thermal barriers.

Each barrier function may be achieved with a dedicated material, but one can serve more than a single prescribed function. In one example, fiberglass-batt insulation functions as a thermal barrier in resisting the transfer of thermal energy across the wall assembly—thus providing the thermal barrier. Above-grade waterproofing membrane, on the other hand, often serves multiple functions and can be used as drainage plane or vapor barrier and can comprise an integral part of the air barrier system (provided certain physical properties are met).

Selecting the appropriate materials and their arrangement within the wall assembly may not always be a straightforward process. Nevertheless, it is essential in preventing moisture-related performance problems. A case in point being the use of low-permeable interior wall finishes in hotels in southern climates during the 1990s, which led to widespread moisture-related problems in exterior walls.

Another example during the 1990s was the use of substandard exterior sheathing materials and improper detailing and installation of the waterproofing layer. This led to moisture-related failures in exterior insulation and finish systems (EIFS) in coastal regions of Canada and warm coastal climates in the United States. Such failures brought about extreme hardship to the owners, insurance companies, and financial institutions involved.

Avoiding failures

The examples of past failures emphasize two critical aspects in ensuring properly functioning building enclosures:

- During project design, proper material selection, sequencing, and integration (i.e. detailing) with adjacent materials in the assembly must be implemented.

- During construction, proper field installation is crucial.

Building enclosures consisting of layered materials—such as board stock insulation, rubberized asphalt membrane, or fluid-applied waterproofing/air barrier and exterior-grade sheathing and porous claddings—require a certain level of building science insight to ensure moisture does not condense and accumulate within the assembly.

Specifying waterproofing/air barrier products with an adequate range of water vapor permeance often necessitates use of advanced engineering analysis to verify the assembly’s hygrothermal response. The general rule of thumb is to locate the vapor barrier toward the interior side of the insulation layer in cold climates and toward the exterior side in warm and humid regions.

In moderate climate zones (where the net water vapor transport across the building enclosure is more balanced), a vapor barrier with low permeance may not be needed. Even with design requirements met on paper, proper field installation is critical to ensure the building enclosure performs well for years to come. With multiple trades involved in construction of a multi-layered wall system, the opportunity exists for mistakes and deficient installation.

Using insulated composite metal panels (IMPs) in building enclosures can simplify the design of the barriers and their installation—since all barriers are integrated into a single unitized component with flashings and sealants to provide a continuous waterproofing, air, vapor, and thermal barrier. From the installation standpoint, using IMPs eliminates the need for multiple trades as the systems are erected by a single trade.

Two questions arise in relation to weather protection, as well as controlling the flow of air, water vapor, and thermal energy:

- What regulatory requirements apply?

- How do building enclosures with IMPs meet them?

It’s interesting that you can have insulated wall panels like this. I can see why it would be a good way to control temperature and rainwater. It’s important to take care of those things, since sitting water can cause a ton of damage over time.