The basics of EPDs

In order to qualify as a low-embodied-carbon material and be selected for projects for which GSA and other federal agencies are using IRA funds, manufacturers must create EPDs to show their GWP.

To understand how EPDs are created, one must understand LCA. LCA is an analysis method developed to, among other things, allow the evaluation of the potential environmental impacts of a product system. Through the use of LCA, models are built of the product system to account for material and energy flows through a system boundary, which are then characterized into potential environmental impacts. Changes to that product system can be evaluated to determine if they improve or worsen the environmental impact of the product. Two standards are used to perform LCA: International Organization for Standardization’s (ISO’s) ISO 14040, Environmental management—Lifecycle assessment—Principles and framework,6 and ISO 14044, Environmental management—Lifecycle assessment—Requirements and guidelines.7

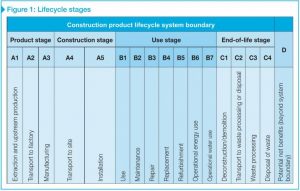

When an LCA is conducted, there is flexibility in the scope of the assessment. One of the more-important scope decisions relates to the lifecycle stages evaluated. Figure 1 shows how various lifecycle stages are categorized in the life of a construction product. At a minimum, all EPDs include lifecycle modules A1, extraction and upstream production; A2, transport to factory; and A3, manufacturing. These modules encompass the “cradle-to-gate” impacts of a product.

When an LCA is conducted, there is flexibility in the scope of the assessment. One of the more-important scope decisions relates to the lifecycle stages evaluated. Figure 1 shows how various lifecycle stages are categorized in the life of a construction product. At a minimum, all EPDs include lifecycle modules A1, extraction and upstream production; A2, transport to factory; and A3, manufacturing. These modules encompass the “cradle-to-gate” impacts of a product.

When an LCA report is developed for a given study, it includes a significant amount of information about the product system and its potential environmental impacts. However, given the complexity of an LCA report, it is not necessarily useful for communicating the potential environmental impacts of a product, which is why EPDs are developed. EPDs are also known as Type III environmental labels (according to ISO 140258) that report a peer-reviewed summary of the results of an LCA.

| LIFECYCLE STAGES |

| There are four lifecycle stages according to the International Organization for Standardization (ISO) 21930 are: production, construction, use, and end-of-life.9 Each lifecycle stage is subdivided into the following modules: • Production: Extraction and upstream production (A1), transport to factory (A2), and manufacturing (A3). • Construction: Transport to site (A4) and installation (A5). • Use: Use (B1), maintenance (B2), repair (B3), replacement (B4), refurbishment (B5), operational energy use (B6), and operational water use (B7). • End-of-life: Deconstruction/demolition (C1), transport to waste processing or disposal (C2), waste processing (C3), and disposal of waste (C4). |

To create an EPD, an LCA practitioner must use several standards:

- ISO 14040 and ISO 14044 to develop the underlying LCA.

- ISO 14025, Environmental labels and declarations—Type III environmental declarations—Principles and procedures,8 as the core product category rule (PCR).

- ISO 21930, Sustainability in buildings and civil engineering works—Core rules for environmental product declarations of construction products and services9 or European Standard EN 15804, Sustainability of construction works. Environmental product declarations. Core rules for the product category of construction products,10 if the product being evaluated is one for use in a building or infrastructure project.

- A subcategory PCR for the product category, if one exists.