Heat flow

When design professionals manage heat, they are trying to keep what is in inside and what is out outside, at least to the best of their abilities. Heat will always try to move from a warm area to a cold zone. The rate of transfer can be slowed by adding insulation between those areas.

When it comes to developing strategies for managing heat flow, the author’s preference is to divide the wall into two sectors: the cavity and the exterior. There are many reasons for this, but the two primary ones for the author are:

- each sector is designed to manage different elements of heat, air, and moisture flow; and

- multiple trades are installing various products on different parts of the wall.

The entire project team, including the architects and contractors, plays a huge role in building the ultimate perfect wall in all phases of a project. From the tradesperson installing the materials onsite to the specifiers designing the assembly, each of these roles need to be considered when designing crucial components and details for wall and roof assemblies.

Air permeable materials (e.g. fiberglass, mineral wool, and cellulose) and products like sprayfoam, radiant barriers, and even hybrid systems combining multiple types of insulation and sealing techniques are employed within the cavity. Vapor impermeable insulations (e.g. expanded or extruded polystyrene [EPS or XPS], polyisocyanurate [ISO], etc.) or vapor permeable materials such as fiberglass or stone wool are utilized on the exterior wall.

The challenge becomes when to choose certain insulations over others and the factors that come into play when making those decisions. For instance:

- external rigid foam board greater than 50 mm (2 in.) thick could address many building code requirements, but there will be challenges in attaching cladding and detailing around windows and it could be cost prohibitive for certain types of construction; and

- external closed-cell sprayed polyurethane foam (ccSPF) can be utilized in both residential and commercial applications, but the foam surface may limit cladding types due to surface irregularity.

When managing heat flow, the goal is to limit heat transfer to improve comfort and protect the building from moisture damage to improve the wall’s durability.

Airflow

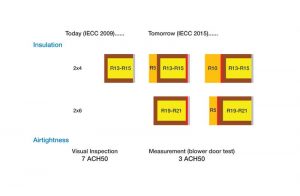

Building codes—particularly standards such as the International Energy Conservation Code (IECC) are focusing on reducing things like air changes per hour (ach) by evaluating them at certain pressure levels (typically 50 Pa [1 psf]) to simulate how air will leak in and out of a building. Tools like infrared (IR) and blower doors can be employed to pinpoint the location of leaks.

Just like heat, there are both interior and exterior strategies to address airflow. Exterior air barrier strategies employ products like fluid-applied membranes, water-resistive barriers (WRBs), and insulation boards. Combining these systems with tapes and joint sealants is a great way to address the leakage paths on the exterior side of the wall.

Interior air barrier strategies include a variety of solutions. SPF can be used to address challenging details (e.g. rim joists) or with hybrid applications in more cost-conscience jobs. It can also be utilized as a full-cavity solution or in conditioned attic assemblies with mechanical equipment. Airtight drywalls, window foam sealants, and caulk and seal packages can also be suitable to address a variety of details from the inside. Newer, more-advanced approaches include the installation of a smart vapor retarder as a continuous air barrier with tapes and sealants. Alternatively, the building team could utilize a similar system integrated with batt insulation that can be simply taped to tackle air, moisture, and heat in a single application.