For most commercially available fenestration systems, test reports outlining the performance attributes of the system—verified through laboratory testing—are available from the manufacturer. These reports are often used to verify a proposed system meets the specified performance criteria.

Test reports typically provide established performance levels for a specific system relative to its ability to resist water penetration and limit air infiltration. However, testing is commonly limited to standard configurations of the system. Therefore, unless stated otherwise, it should not be assumed the reported performance criteria apply to the many variations, or options, offered by the manufacturer.

Some options, such as custom snap cover profiles, have little-to-no adverse effects on system performance. However, other optional features or configurations that modify the various control features, or alter how the system is intended to integrate with adjacent assemblies, can impact performance and/or required detailing. As such, in situations where an optional configuration is being considered for a project, understanding how it may affect the performance, detailing, and installation sequencing of a system is essential.

For example, curtain wall and storefront system designs commonly incorporate critical internal seals and drainage provisions to control air and water flow. Alternative anchor configurations or subsills can result in fastener penetrations through the wet zone of the system or the interruption of a critical seal—which would require modifications to the installation sequencing and/or detailing to maintain the intended performance.

Other system variations, such as optional perimeter extrusion profiles, could affect the positioning of the perimeter primary seals and would require adjustments to interface detailing to ensure air and water control layers are being properly maintained at transitions between enclosure systems. Storefront systems generally have various subsill options that can have a significant effect on water penetration resistance; therefore, it is important to understand the performance attributes, and any special detailing required, for each of the subsill options prior to selection.

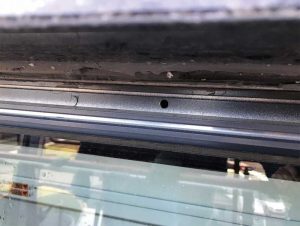

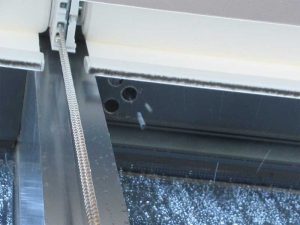

On a recent project where the vertical enclosure consisted of alternating horizontal bands of a ribbon window wall system interrupted by a panelized rainscreen assembly, the window wall was installed with an optional head extrusion. The intended purpose of this component was to capture incidental water that migrated into the window system from the panel system above, in what would be considered the “dry” zone of the standard system, and redirect it to the exterior via weep holes.

In addition to incorporating drainage provisions, this optional extrusion required several internal seals to prevent water and unconditioned air from entering the building—seals that were not installed as they were not necessary in the “standard” system for which the manufacturer’s test report applied. Although intended to drain water from the head extrusion, the weep holes also allowed bulk water (and unconditioned air) within the glazing pocket to flow into the head extrusion, and eventually into the building, because the additional internal seals were not provided during installation. This led to significant water leakage during prolonged, wind-driven rain events. Further, additional uncontrolled air flow was detected during evaluation of the as-built assembly. The lack of appropriate detailing, in addition to the installer’s unfamiliarity with the optional extrusion with the subject system, resulted in significant performance issues of the as-installed window wall.

The opinions expressed in Failures are based on the authors’ experiences and do not necessarily reflect that of The Construction Specifier

or CSI.

Jeffrey Sutterlin, PE, is an architectural engineer and associate principal with the Princeton, New Jersey, office of WJE, specializing in investigation and repair of the building envelope. He can be reached at jsutterlin@wje.com.

Jeffrey Sutterlin, PE, is an architectural engineer and associate principal with the Princeton, New Jersey, office of WJE, specializing in investigation and repair of the building envelope. He can be reached at jsutterlin@wje.com.

David S. Patterson, AIA, is an architect and senior principal with WJE’s office in Princeton, New Jersey. He specializes in investigation and repair of the building envelope. He can be reached at dpatterson@wje.com.

David S. Patterson, AIA, is an architect and senior principal with WJE’s office in Princeton, New Jersey. He specializes in investigation and repair of the building envelope. He can be reached at dpatterson@wje.com.