Architectural applications

Architects designing with cantilevered beams, concrete balconies, roof penetrations, canopies, spandrel glass, and ornamental architectural features must address the cold-to-hot issue.

At these moments in the design, moisture formation has to be addressed or problems can occur or the creative approach would have to be scaled back.

For architectural applications, the thermal performance of fluid-applied acrylic insulation coating was recently documented by a Morrison Hershfield report commissioned by a coatings manufacturer. The findings were very promising for various common construction details, including:

- any structural steel beams that bypass the thermal insulation;

- structural clips for cladding of exterior insulated assemblies;

- steel stud assemblies; and

- concrete slabs.

The testing by Morrison Hershfield included three thicknesses of the coating: thicknesses at 1520 and 3050 µm (60 and 120 mil) and 13 mm (½ in.) using a conductivity of 0.0356 W/m KL (0.0202 Btu/hr ft F). The thermal analysis, employing steady-state conditions and published thermal properties, was completed with 3-D heat transfer software.

Unlike structural thermal break products, insulated coatings do not require additional engineering to determine whether they will support the load. Coatings can also be more cost-effective than structural products once steel, fabrication, installation, and specialized bushings and washers are factored into the equation. As no additional engineering work is needed to create physical thermal breaks, the aerogel coatings can be shop- or field-applied, and can be used for both construction or retrofit projects.

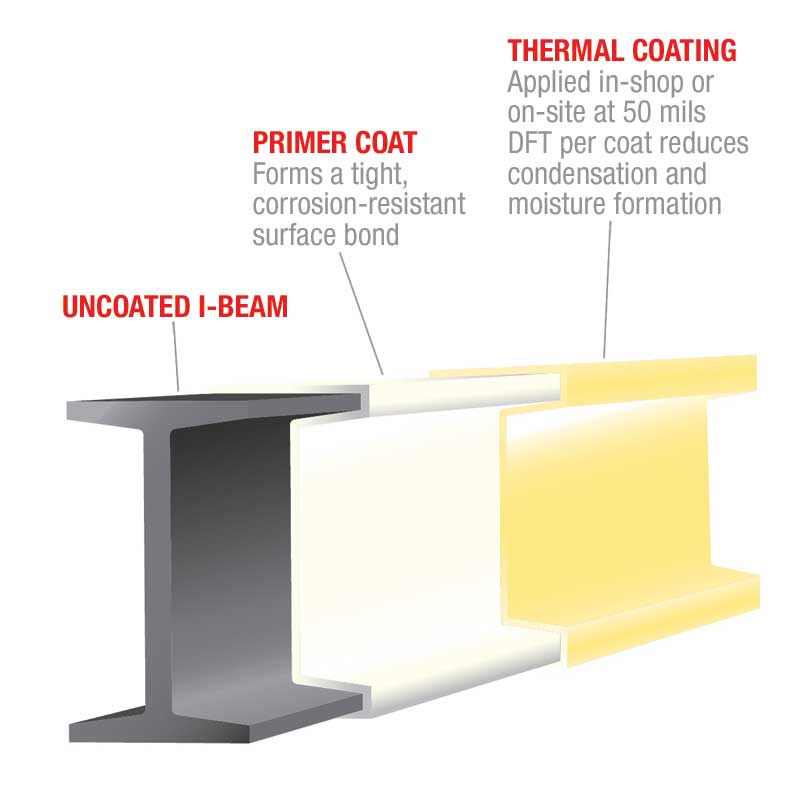

Thermal coatings work by providing thermal conductivity levels at 35 mW/mk, compared to 260 mW/mk for thermal-break pads. The thermal insulating coating changes the surface temperature enough that moisture does not condense even without a physical break in the beam.

Rowan O. Georges, AIA, an associate director at Skidmore, Owens & Merrill LLP (SOM), says he has specified the product on canopies, parapets, balconies, and inside curtain walls, and uses the product for both concrete and steel structural details, especially in high-rises.

“I am impressed with the thermal properties of the product. This is a good solution to the problem,” he explains, citing the versatility of the thermal coatings and its self-extinguishing characteristics as benefits for designing thermally enhanced high-rise buildings. “This product has proven to be very beneficial.”

The significant reduction in heat loss equals a slab or structural steel component that in many conditions will be warm enough in order to avoid condensation.

Overall, design professionals see the potential for cost reductions compared to structural products with aerogel coatings and the prospect of simpler specifications. Manufacturers have drawings and specifications with construction details available for keeping interiors warmer and avoiding condensation and mold formation within the building envelope.

LEED, energy, and IAQ

The LEED energy efficiency credits referencing ASHRAE 90.1-2010 will gain the most contributions with thermally broken designs. Indirectly, the new design approach will play a role in assisting with Indoor Environment Quality (EQ) Credit 5, Thermal Comfort.

The overall energy benchmark ASHRAE 90.1-2010 is used by project teams to meet energy codes and voluntary green building programs. However, some mid-rise multi-family projects at four or more stories tall could be covered by the LEED for Homes Rating System: Multi-family Mid-rise. In LEED for New Construction (NC), healthcare projects must develop a moisture control plan per EQ Credit 3, Construction Indoor Air Quality Management Plan.

The continuous insulation (ci) requirements in energy codes are enhanced by thermal break design details. Often, much attention is paid to upgrading HVAC and lighting systems with increased R-values in the building envelope. Fluid-applied thermal coatings have the potential to create additional energy efficient upgrades to the exterior facing systems.

The latest versions of the International Energy Conservation Code (IECC) and ASHRAE 90.1 require increased energy performance design details. Building energy performance upgrades to include more efficient HVAC, lighting, and insulation systems are not always enough while maintaining the building owner’s desires for unique aesthetics and flexible design requirements. ASHRAE 90.1-2010 and the 2012 IECC call for the additional step of ci throughout the entire building envelope. Once all these requirements have been met, thermal break coatings can assist project teams with the new energy codes.