Fluid-applied thermal break coatings 101

by Katie Daniel | December 2, 2015 11:54 am

[1]

[1]by Paul Nutcher, CSI, CDT, AIA Allied

Architects designing with concrete balconies, cantilevered beams, roof penetrations, parapets, canopies, spandrel glass, and other ornamental architectural features are often limited in executing these design elements because they can create thermal bridges that extend beyond the insulation systems within the building envelope. This can cause condensation buildup in exterior systems and significant loss of energy performance for the whole building. Both issues can hamper efforts at designing and constructing buildings to meet energy codes or buildings registered under one of the voluntary green building rating systems. Fluid-applied insulating coatings can help.

While much attention is paid to roof and wall assemblies and their R-values (or lower heat flow, U-values), meeting code-mandated requirements and the benchmarks in voluntary green building rating programs such as Leadership in Energy and Environmental Design (LEED) or Green Globes will challenge project teams. They will need to find every possible thermal bridge during pre-design to improve the assembly’s energy efficiency.

Thermal bridging can have a significant impact on a project from a cost and compliance standpoint. Heat flows determine the building’s heating and cooling system capacity, long-term energy costs, compliance with energy codes, and voluntary energy performance code-overlay programs. How building assembly materials are arranged in the envelope determines surface temperatures, moisture development, long-term durability, and the potential for mold growth within outward-facing building systems.

Much has been done in recent decades to address inaccuracies in HVAC sizing because previous generations of energy modeling did not take into account the interface details, which can have an impact of as much as 50 percent on the overall wall area. According to Oak Ridge National Laboratories (ORNL) experts Jan Kosny and Jeffrey E. Christian, more accurate thermal performance measurements[2] will have to include typical envelope details such as wall/wall (i.e. corners), wall/roof, wall/floor, wall/door, and wall/window connections. This is in addition to measuring the thermal performance of the ‘clear wall’ area, insulation layers, and the structural elements.

By the mid-1990s, ORNL research led to ‘whole-wall’ R-value estimations, compared with simplified ‘center-of-cavity’ and ‘clear-wall’ R-values. However, much of that work dealt with residential single-family dwellings. Over the last few decades, there has been a natural progression in research on commercial mid-rise and high-rise construction.

Studies in thermal bridging

Before delving into the new class of fluid-applied insulating coatings, it is important to understand how heat is transferred within a building envelope. American Society of Heating, Refrigerating, and Air-conditioning Engineers’ (ASHRAE’s) Research Project (RP) 1365, Thermal Performance of Building Envelope Details for Mid- and High-rise Buildings, initiated a catalog of thermal performance data

for 40 common building details for mid-rise and high-rise construction. Published in 2011, its goals were to:

- calculate thermal performance data for common building envelope details for mid-rise and high-rise construction;

- develop procedures and a catalog that allowed designers quick and straightforward access to information; and

- provide information to answer the fundamental questions of how overall geometry and materials affect the overall thermal performance.

Engineers at Morrison Hershfield employed heat-transfer software, and calibrated and validated models against measured and analytical solutions. International Organization for Standardization (ISO) standards for glazing were used, as were 29 guarded hot box test measurements. They assessed 40 construction details common to construction methods in North America. While there was some focus on glazing, the highest priority was on the details with thermal bridges in three dimensions.

[3]

[3]The research project was initiated when ASHRAE 90.1-2007, Energy Standard for Buildings Except Low-rise Residential Buildings, was the most ubiquitous standard applied in some state energy codes and in Energy & Atmosphere (EA) prerequisite and credits in LEED 2009 for determining whole building energy performance. (The current version of the building rating system is set to be updated to LEED v4 in October 2016.) However, ASHRAE 90.1-2007 largely avoided the thermal bridging of outside assemblies, according to Mark Lawton, P.Eng., FEC, of Morison Hershfield’s Vancouver office (He credits their work in this field to his colleagues, Patrick Roppel, M.A.Sc., P.Eng., and Neil Norris, M.A.Sc., EIT.)

The Morison Hershfield team applied a European method to streamline the assessments of various assemblies by looking at the assemblies’ heat flow with the thermal bridge versus without it for a linear transmittance measurement. The researchers took the advice of the ORNL and began to account for several construction details previously not considered in earlier energy modeling programs.

Since the ASHRAE project, more has been developed for industry professionals who have been tasked with designing energy-efficient building envelopes, especially in situations where lateral heat flow is affecting thermal performance of the assembly via linear transmittance (or thermal bridging). In August 2014, Morrison Hershfield and Canadian utility BC Hydro published Building Envelope Thermal Bridging Guide: Analysis, Applications, and Insights[4], which serves as a resource for designers and specifiers as they confront mitigation of thermal bridging and reducing energy consumption in buildings. It addresses several issues challenging project teams today and addresses those challenges by:

- cataloguing the thermal performance of common building envelope assemblies and interface details;

- providing data-driven guidance that makes it easier for the industry to comprehensively consider thermal bridging in building codes and bylaws, design, and whole building energy analysis;

- examining costs associated with improving the thermal performance of opaque building envelope assemblies and interface details, and forecasting the energy impact for several building types and climates; and

- evaluating cost-effectiveness of improving the building envelope through more thermally efficient assemblies, interface details, and varying insulation levels.

[5]

[5]Fluid-applied thermal

break coatings

Due to new products and baseline energy performance data, construction details are now available for insulating steel and concrete penetrations. These coating products help give project teams new freedom for creative design for net-zero-energy buildings that can also address condensation resistance and energy efficiency when they are applied to structural building elements bypassing the insulated portions of the building envelope (Many of the insulation coatings have been tested with a variety of different primers and topcoats, so there is a system for most substrates and environments. Some manufacturers have tested their coatings with different intumescent and cementitious fireproofing products to ensure they have be approved for use in fire-resistive assemblies.)

Insulated coatings have been infused with fillers to produce a low-conductivity material that can be applied while in its fluid form. Fillers can be ceramic

or glass spheres, which can provide thermal conductivity in the 70 to

100 mW/mK range. Or, newer fillers like aerogel particles can help provide

a thermal conductivity as low as

35 mW/mK. In other words, an acrylic coating can stop the process of heat convection via a steel beam; once this is combined with an aerogel coating,

it also reduces convective heat loss (Aerogels are synthetic porous ultralight materials with low density and thermal conductivity. Essentially, they are gels where the liquid component has been replaced with a gas.)

Often, the beneficial attributes of a product developed for one use can also be repurposed to serve another role. This was the case for fluid-applied thermal break coatings, which were initially developed in 2010 to provide ‘bump protection’ (i.e. safe-to-touch applications) to protect skin-to-hot-pipe contact within certain workplace environments such as along steam pipelines and also in boiler rooms. A proprietary product first developed for deep-sea pipelines was introduced into acrylic coatings for this purpose, and testing proved its beneficial thermal performance on extremely hot surfaces.

According to Greg Pope, co-author of Aerogel Fluid-applied Coatings Solution for Thermal Bridging for Design Community, interest for architectural use grew quickly after the thermal performance test results were discovered.

“The low thermal conductivity of 12 mW/mK make aerogel 50 percent more efficient than still air,” he explained. “Once incorporated into a coating at very low film thickness, the aerogel coating at [1520 to 3800 µm] 60 to 150 mils reduced heat transfer by 47 to 51 percent.”

In order to put this in context, a person could touch a 150-C (300-F) metal pipe for approximately 10 seconds, without any burns, if it had been insulated with a fluid-applied thermal break coating. The aerogel-infused coating insulates the pipe, lowing the surface temperature of the coating to approximately 38 C (100 F).

[6]

[6]Architectural applications

Architects designing with cantilevered beams, concrete balconies, roof penetrations, canopies, spandrel glass, and ornamental architectural features must address the cold-to-hot issue.

At these moments in the design, moisture formation has to be addressed or problems can occur or the creative approach would have to be scaled back.

For architectural applications, the thermal performance of fluid-applied acrylic insulation coating was recently documented by a Morrison Hershfield report commissioned by a coatings manufacturer. The findings were very promising for various common construction details, including:

- any structural steel beams that bypass the thermal insulation;

- structural clips for cladding of exterior insulated assemblies;

- steel stud assemblies; and

- concrete slabs.

The testing by Morrison Hershfield included three thicknesses of the coating: thicknesses at 1520 and 3050 µm (60 and 120 mil) and 13 mm (½ in.) using a conductivity of 0.0356 W/m KL (0.0202 Btu/hr ft F). The thermal analysis, employing steady-state conditions and published thermal properties, was completed with 3-D heat transfer software.

Unlike structural thermal break products, insulated coatings do not require additional engineering to determine whether they will support the load. Coatings can also be more cost-effective than structural products once steel, fabrication, installation, and specialized bushings and washers are factored into the equation. As no additional engineering work is needed to create physical thermal breaks, the aerogel coatings can be shop- or field-applied, and can be used for both construction or retrofit projects.

Thermal coatings work by providing thermal conductivity levels at 35 mW/mk, compared to 260 mW/mk for thermal-break pads. The thermal insulating coating changes the surface temperature enough that moisture does not condense even without a physical break in the beam.

Rowan O. Georges, AIA, an associate director at Skidmore, Owens & Merrill LLP (SOM), says he has specified the product on canopies, parapets, balconies, and inside curtain walls, and uses the product for both concrete and steel structural details, especially in high-rises.

“I am impressed with the thermal properties of the product. This is a good solution to the problem,” he explains, citing the versatility of the thermal coatings and its self-extinguishing characteristics as benefits for designing thermally enhanced high-rise buildings. “This product has proven to be very beneficial.”

[7]

[7]The significant reduction in heat loss equals a slab or structural steel component that in many conditions will be warm enough in order to avoid condensation.

Overall, design professionals see the potential for cost reductions compared to structural products with aerogel coatings and the prospect of simpler specifications. Manufacturers have drawings and specifications with construction details available for keeping interiors warmer and avoiding condensation and mold formation within the building envelope.

LEED, energy, and IAQ

The LEED energy efficiency credits referencing ASHRAE 90.1-2010 will gain the most contributions with thermally broken designs. Indirectly, the new design approach will play a role in assisting with Indoor Environment Quality (EQ) Credit 5, Thermal Comfort.

The overall energy benchmark ASHRAE 90.1-2010 is used by project teams to meet energy codes and voluntary green building programs. However, some mid-rise multi-family projects at four or more stories tall could be covered by the LEED for Homes Rating System: Multi-family Mid-rise. In LEED for New Construction (NC), healthcare projects must develop a moisture control plan per EQ Credit 3, Construction Indoor Air Quality Management Plan.

The continuous insulation (ci) requirements in energy codes are enhanced by thermal break design details. Often, much attention is paid to upgrading HVAC and lighting systems with increased R-values in the building envelope. Fluid-applied thermal coatings have the potential to create additional energy efficient upgrades to the exterior facing systems.

The latest versions of the International Energy Conservation Code (IECC) and ASHRAE 90.1 require increased energy performance design details. Building energy performance upgrades to include more efficient HVAC, lighting, and insulation systems are not always enough while maintaining the building owner’s desires for unique aesthetics and flexible design requirements. ASHRAE 90.1-2010 and the 2012 IECC call for the additional step of ci throughout the entire building envelope. Once all these requirements have been met, thermal break coatings can assist project teams with the new energy codes.

[8]

[8]Further, the health benefits of a building with a reduced potential for mold growth in wall systems are desirable in LEED projects and for building owners who want to avoid litigation due to Sick Building Syndrome (SBS). The warmer interior temperature of the structural members of the building can decrease condensation and assist in the prevention of mold.

LEED NC v4 will address the thermal comfort of occupants in its EQ Credit 5, Thermal Comfort. The relevant standard is ASHRAE 55-2010, Thermal Comfort Conditions for Human Occupancy, with errata or local equivalent. Without thermal bridging within the building envelope, project teams that design thermally broken balconies can meet the requirement of LEED v4 Credit 5.

The compatibility of air and vapor barriers—along with sealants, cementitious materials, and intumescent fireproofing—is critical for building envelope code requirements. Thus, the inadvertent development of an aerogel-filled thermal break coating is a workable solution to a nagging design problem.

Interior and exterior areas where thermal bridging is a concern

Among windows within interior rooms where the relative humidity can reach high levels in the cold winter months and thermal bridging has not been mitigated, the ice buildup on the windows can present moisture issue to the materials and systems surround the opening. As the ice melts, the moisture can migrate to the drywall and damage the interior walls, as well as provide moisture for mold growth.

To mitigate the surface temperature of the window frames, an aerogel-insulated coating can be applied to raise conditions above the dewpoint to greatly reduce and potentially eliminate condensation. For example, an existing aluminum window frame within a high relative humidity (RH) room with an outside temperature of −2 C (28 F) will go from a spot surface temperature reading of 8.4 to 20.3 C (47.1 to 68.5 F), once 2794 µm (110 mils) of the aerogel coating has been applied.

Another common area within the interior of the building affected by condensation is where the walls and ceilings meet at a corner—mold can be noticeable at these locations. At the intersection of the interior and exterior on multi-family construction, balconies are also common sources of heat loss and condensation issues. The balcony slab extends to the outside air, exposing the entire slab to exterior temperatures via thermal bridging; the intersection of the low and high energy temperatures heating and cooling energy throughout the building is often lost—any exterior systems in contact or nearby will absorb more moisture from condensation than they can withstand.

[9]

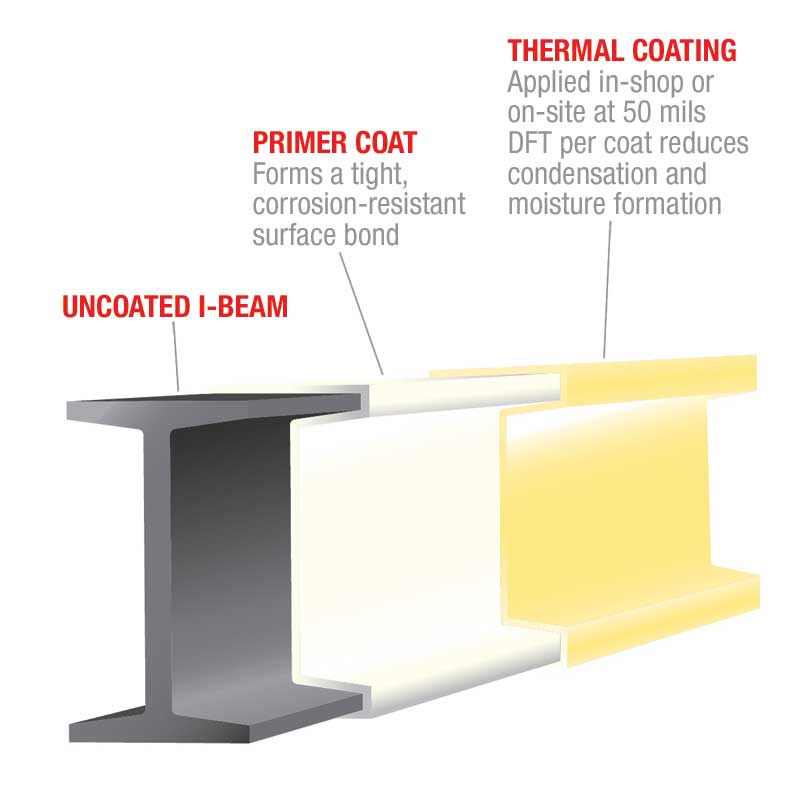

[9]Application of insulated coatings

For insulating the building envelope, fluid-applied insulated coatings cannot replace dry insulation methods, but they can help achieve optimal energy efficient performance of the building envelope. Corrosion resistance is achieved with

a primer applied to the substrate prior to applying the coating. Often, a finish coat is also applied for aesthetic or other reasons, such as ultraviolet protection or chemical resistance.

The use of zinc-rich primers is not generally recommended when in-service temperatures exceed 49 C (120 F) (Reference NACE SP0198, Control of Corrosion Under Thermal Insulation and Fireproofing Materials, for further information.)

Conclusion

A fluid-applied, thermal insulating coating utilizing aerogel particles can impart exceptional insulative properties to a variety of substrates. Within buildings, these new systems are ideal for structural steel or other substrates where thermal improvement is desired.

Communication is key for the project team members charged with the energy efficiency performance and condensation control of the building. It is equally important for the manufacturer, contractor, and structural engineer to communicate and share information about this important intersection point in a building where cold air meets higher-energy hot air.

| DANGERS OF CONTINUOUS CONDENSATION CYCLES |

|

Structural steel beams’ hardware or welds that remain wet due to moisture infiltration can weaken, leading to potentially costly building code violations or mitigation projects. A worse result is structural failure—especially when leaking exterior systems exacerbate the issue compounded with heavy snow loads and chlorine rock salt that has been applied for years on roof pavers. These cases are rare, but have happened.* Insulated fluid-applied coatings were first used on boilers and pipelines where preventing steel corrosion under insulation (CUI) was of vital concern. Corrosion can attack the jacketing, insulation hardware, or the underlying steel. The National Board of Boiler and Pressure Vessel Inspectors is a great resources for further information on steel corrosion under insulation. Insulated fluid-applied coatings are durable, corrosion-resistant products that bond to the substrate, greatly reducing the issues associated with CUI. Once moisture and thermal protection exterior systems have been installed, the properly installed insulated coating will provide peace of mind to the project team, and building owners and occupants, for decades to come. * See the 2012 forensic engineering investigation report into the Algo Centre Mall Collapse in Elliot Lake, Ont. |

Paul Nutcher, CSI, CDT, AIA Allied, is the president of Green Apple Group LLC, a marketing, technical, and sustainability consulting firm. A LEED Green Associate, he has more than 10 years of building industry experience as a specifications and technical writer, educator, and consultant to product manufacturers and design/construction professionals. Nutcher has served in leadership roles with CSI, the U.S. Green Building Council (USGBC), and the American Institute of Architects (AIA). He can be reached at pnutcher@greenappleconsult.com[10].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/4.jpg

- thermal performance measurements: http://web.ornl.gov/sci/roofs+walls/research/detailed_papers/Whole_Wall_Therm/

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/1.jpg

- Building Envelope Thermal Bridging Guide: Analysis, Applications, and Insights: http://www.bchydro.com/content/dam/BCHydro/customer-portal/documents/power-smart/builders-developers/thermal-guide-launch-presentation_ml_2014-10-16-opt.pdf

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/7.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/5.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/DSC_3521.jpg

- pnutcher@greenappleconsult.com: mailto:pnutcher@greenappleconsult.com

Source URL: https://www.constructionspecifier.com/fluid-applied-thermal-break-coatings-101/