Exterior panel

Transparent (e.g. monolithic glass, insulating glass unit [IGU]), semitransparent (e.g. ceramic frit-coated glass), or opaque panels (e.g. opacified glass, metal panel, terracotta, stone).

Air cavity

Either vented to the exterior or sealed (unvented), typically 25 mm (1 in.) deep minimum. (Note, venting design includes items such as vent/weep hole size, quantity, location, and baffling, resulting in pressure equalization of the air cavity to the exterior and is often determined based on a combination of computational analysis, empirical test data, and past experience.)

Intermediate panel

Typically, an intermediate metal panel provides a visual surface through the glass. This is generally included when paired with transparent or semitransparent exterior panels (e.g. vision glass) to visually conceal the insulation. This would constitute a ‘shadow box’ spandrel design. In an opaque glass spandrel design, this layer would be omitted since it would be obscured by the opaque exterior panel.

Insulation

Typically, semi-rigid mineral wool.

Interior membrane/back-pan

The interior membrane can be a foil-facer membrane laminated to the insulation (functioning as an interior vapor retarder) and taped airtight to the perimeter framing. The other option is a metal back-pan (functioning as an interior air-vapor barrier or possibly, if detailed properly, as an interior air-water-vapor barrier), anchored and sealed to the perimeter framing.

Glass spandrel types and design considerations

Illustration courtesy Simpson, Gumpertz & Heger and Oldcastle Building Envelope

Terminology for glass spandrel types can vary within the industry. The following will provide some clarity and definitions. Glass spandrel types generally include:

- opaque spandrel glass;

- traditional shadow box;

- touch-mullion shadow box; and

- open shadow box.

The term ‘traditional’ shadow box is used to differentiate between other shadow box types. The following summarizes these glass spandrel types and discusses a variety of design considerations, including heat build-up, condensation risks, air-water-vapor seal, structural integrity, and access for cleaning and maintenance.

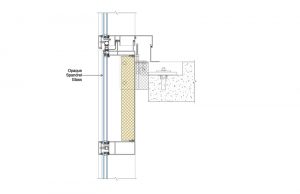

Opaque spandrel glass

Opaque glass spandrels include an opacified glass exterior panel (Figure 2). The opaque glass panel can be either an IGU or non-insulating (e.g. monolithic or laminated glass). The glass can be opacified in a variety of ways, including a full-coverage of ceramic frit (typically on the #3 or #4 surface of an IGU), back-painted glass, opaque laminate interlayer, or an applied opacifier plastic film.

Typically, this opaque glass is referred to as ‘spandrel glass.’ Often, the spandrel glass can be a similar buildup (e.g. overall IGU thickness, low emissivity [low-e coating, typically on the #2 surface) as the adjacent vision glass to provide visual continuity across the façade. If the exterior reflectivity of the vision glass and spandrel glass are high (e.g. typically a function of the low-e coating used), the visual transition from vision to spandrel glass can appear quite seamless.

Illustration courtesy Simpson, Gumpertz & Heger and Oldcastle Building Envelope

Spandrel glass will generally block solar heat from passing through and into the building, which would otherwise need to be managed by the building’s mechanical system. Although much of the solar heat will be blocked by the spandrel glass, some heat will be absorbed by the glass and insulation (and be re-radiated). This can lead to differential thermal stress within the glass panel. For this reason, the lites of spandrel glass often need to be heat-treated.

Risk of condensation within a spandrel glass assembly will depend upon details of the construction (e.g. vented or unvented cavity, insulation thickness, detailing and sealing of the interior membrane/back-pan), the exterior climate, conditions within the cavity (e.g. built-in moisture), and the building interior psychometric conditions (i.e. temperature and relative humidity). However, if condensation forms, it is unlikely to be visible from the exterior due to the opaque nature of the glass. In addition, the presence of dust/debris behind the glass is also likely to go unnoticed.

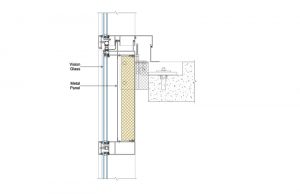

Traditional shadow box

The makeup of a traditional shadow box is like spandrel glass; however, instead of opaque glass, the glass is transparent or semitransparent (e.g. partial frit coverage), and is paired with an intermediate panel (Figure 3). The intermediate panel is typically a metal panel which is used to visually conceal insulation behind. The intermediate panel can be any number of geometries, configurations, or colors. This assembly allows for greater visual depth and continuity with the adjacent vision glass. The glass in a traditional shadow box is typically the same (or similar) buildup as the vision glass.

Illustration courtesy Oldcastle Building Envelope

Like spandrel glass, a shadow box will generally block solar heat from passing through the assembly and into the building. Because the glass is transparent solar heat will build up in the cavity behind the glass, however. The amount of solar heat buildup will depend on the construction details (e.g. IGU or non-insulating glass, low-e coating type, vented or unvented cavity, color of metal panel, insulation thickness) and project-specific climate (e.g. building location, solar orientation) and needs to be carefully considered by the designer.

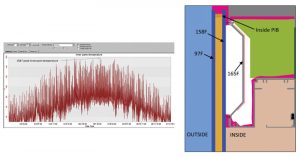

Typically, project-specific finite element analysis (FEA) is required to accurately calculate heat buildup within the cavity (Figure 4). Excessive solar heat buildup within the cavity can be problematic. It can result in a variety of issues such as glass bowing and/or breakage, buckling (oil-canning) of metal panels, and off-gassing and degradation of materials, amongst other adverse effects. As a result, glass in shadow box assemblies is often heat-treated (to reduce risks of glass breakage), metal panels are often solid metal plate panels (i.e. not composite metal panels, which can lead to off-gassing), attachment of the intermediate panel to perimeter framing is designed to allow for thermal expansion/contraction, and the air cavity can be vented.