Illustration courtesy Simpson, Gumpertz & Heger and Oldcastle Building Envelope

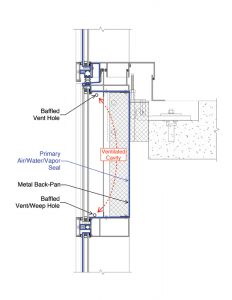

If the shadow box is vented, it is typically vented to the exterior. This is advantageous in the winter in cold climates when the outside air is cold and dry which helps to dehumidify the shadow box cavity. On the other hand, venting the cavity to the interior would likely result in the introduction of moisture from the building interior causing condensation within the assembly during cold winter weather (e.g. evening, night, or morning during cold exterior temperatures).

When vented to the exterior, the primary air-water-vapor seal of the system must be provided by either the intermediate metal panel or the metal back-pan. This metal panel must be fully sealed to the perimeter framing, including sealing the framing joinery (e.g. vertical-to-horizontal mullion interface) and all fastener penetrations through the metal panel (Figure 5). When vented to the exterior, this metal panel must also be designed to accommodate wind loads. Note, when venting to the exterior, a foil-facer on the thermal insulation (which is typically only taped to the perimeter framing from the interior) will unlikely have adequate structural capacity to resist applied wind loads and should not be designed to function as the primary air and water barrier. Therefore, with a vented design, the metal panel (either intermediate panel or the metal back-pan) must be sealed.

Illustration courtesy Simpson, Gumpertz & Heger

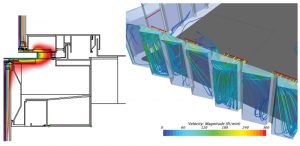

Condensation risks at shadow boxes are like those described previously for spandrel glass and often require FEA analysis (in some cases computational fluid dynamics [CFD] modeling) to assess risks (Figure 6). Because shadow boxes are transparent/translucent, unlike spandrel glass, if condensation forms it can be readily visible from the exterior. If the assembly is vented to the exterior, the condensation may eventually dissipate (as described in the example at the introduction of this article). Prolonged periods of high exterior humidity can lead to a perception of a problem notwithstanding a possible visual objection. Use of IGUs compared to monolithic/laminated glass often tends to provide additional condensation mitigation during fast-changing exterior temperature conditions (e.g. like early morning dew formation in the summer, when the exterior temperature drops at night or morning before the sun has a chance to warm exterior surfaces).

Illustration courtesy Simpson, Gumpertz & Heger and Oldcastle Building Envelope

In addition to condensation risks, if the venting is not properly designed and/or constructed, dust/debris from the outside environment can enter the cavity. Should this occur, it can result in the appearance of a film on the glass which may also lead to streaking from condensation. If dust/debris or streaking occurs, it is generally considered trapped as the interior surfaces of the shadow box are inaccessible. To clean the surfaces, the glass would need to be deglazed (from the exterior), cleaned, and reinstalled. This procedure presents its own challenges as reglazing requires the skill of a glazing subcontractor and carries the costs associated with glass replacement (and if the glass is structural silicone-glazed, additional technical challenges of reglazing structural silicone in the field). Further, access equipment may be perceived as an unacceptable maintenance exercise.

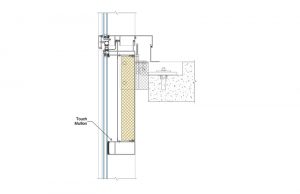

Touch-mullion shadow box

A touch-mullion shadow box is constructed and functions like a traditional shadow box. However, instead of providing a separate piece of glass at the shadow box, the adjacent vision glass panel extends into the spandrel zone, resulting in a single-vision glass panel (Figure 7). A mullion is typically provided to separate the vision zone from the spandrel zone which is often sealed to the inside of the glass with structural silicone. This assembly allows for an even greater seamless visual transition as there is no longer an exterior split between vision and spandrel zones.