Photo © Steve Wanke Photography

PVDF versus polyester

After 40 years of UV exposure, PVDF and polyester coatings react differently in exterior environments. As Figure 3 indicates, both coatings will have a slight shift in color fade and chalk values in the initial five years of exposure; over time, the differences in their composition will become clearer.

While PVDF coatings have a very gradual decline in color fade and chalk over a 40-year period, polyester coatings match PVDF coatings for a time, then abruptly lose performance. On average, durable polyesters may have half the life expectancy of PVDF coatings, which severely limits their long-term performance.

The benefits of adding a clear coat

PVDF coatings are available as two- or three-coat systems, with the third coat representing the application of a clear topcoat. A clear coat is required for coatings with metallic flake to prevent tarnishing and discoloration from UV exposure, but they also are recommended to protect and enhance coatings formulated with solid color and micas, or to provide longevity to coatings made with weaker pigments.

Another oft-overlooked benefit of clear coats is they minimize dirt accumulation and make metal building surfaces easier to clean. This is critical in severe industrial environments or coastal areas where buildings can be exposed to chemical fallout or salt spray (Figure 4).

Resistance to UV exposure is also enhanced with a clear coat, as demonstrated in Figure 5, allowing manufacturers to provide improved warranties for chalk and fade.

Conclusion

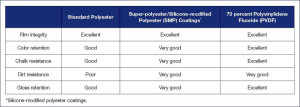

In recent years, some manufacturers have sought to position SMP and super-polyester coatings as viable, lower-cost alternatives to 70 percent PVDF coatings; however, the latter will always provide better long-term performance because of the inherently superior chemical and molecular structure. Nevertheless, there are applications for which SMP and super-polyester coatings can be favored over 70 percent PVDF coatings, particularly when long-term color and gloss retention are less of a priority than cost control and basic durability.

Warranties for coil coatings are not a reliable indicator of coatings performance. When comparing warranties for SMP, super-polyester, and 70 percent PVDF coil coatings, architects and specifiers should scrutinize their length and terms, particularly for performance factors such as chalk and fade. They should also be wary of test data that does not extend beyond five to 10 years because it does not effectively represent the long-term performance expectations associated with most high-end commercial and residential architectural applications.

Scott W. Moffatt is PPG Industries’ marketing director for coil and extrusion coatings. He is a 34-year veteran of the company and has held global positions covering sales, sales management, and marketing for multiple technologies and market segments in the industrial coatings market. Moffatt is a member of Metal Construction Association (MCA), The Metal Initiative (TMI), Metal Roofing Alliance (MRA), Metal Building Manufacturers Association (MBMA), National Coil Coating Association (NCCA), and Cool Roof Rating Council (CRRC). He can be reached at moffatt@ppg.com.