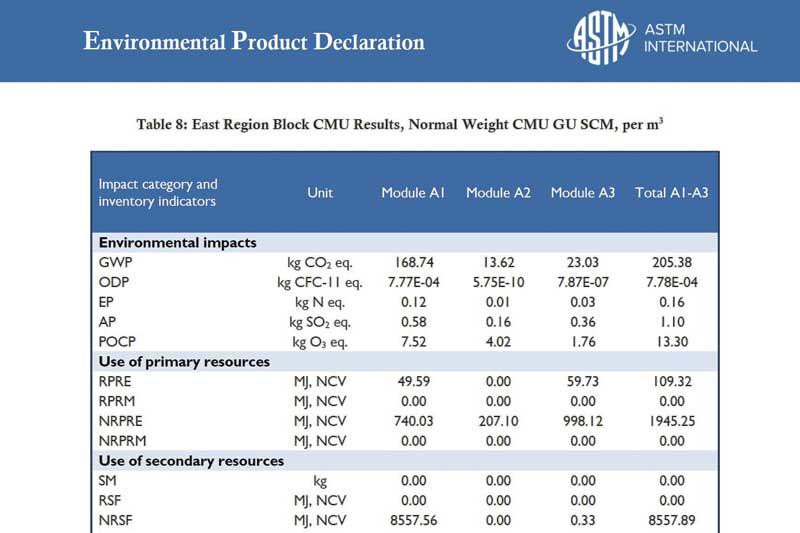

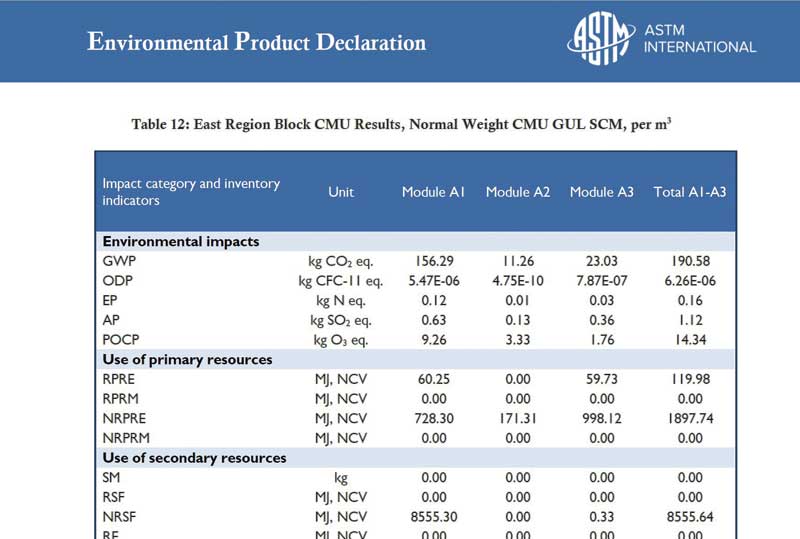

EPDs can be nationally averaged or plant-specific. Plant-specific EPDs provide more points in the LEED certification system as they are regarded as more accurate than nationally averaged EPDs. EPDs for concrete masonry products are also now available. Figure 2 provides an excerpt from the Canadian Concrete Masonry Producers Association’s (CCMPA’s) nationally averaged EPD3 for Eastern Canada producers with an averaged global warming potential (GWP) at 205.38 kg (452 lb) of CO2eq when using GU Portland cement to manufacture the normal weight CMUs; while Figure 4 provides the Eastern Canada producers averaged GWP at 190.58 kg (420 lb) of CO2eq when using GUL to manufacture the normal weight CMUs. From these values, it can be seen as the substitution of GUL for the GU cement in the manufacture of concrete block products resulting in a 7.7 percent reduction in the GWP of concrete masonry products.

Carbonation of CMU

There are two methods showing how CMUs absorb CO2: weathering carbonation and pre-carbonation (carbon curing).

Weathering carbonation occurs as concrete, used to manufacture the concrete block, and the mortar joints used to assemble a block wall, mature due to the reaction of CO2. This happens when moisture is present with the hydrants (i.e. alkalis) in concrete block, mortar joints, and grout. Specifically, CO2 from the atmosphere diffuses into the capillary pores and combines with the water to form carbonic acid.3 The rate of CO2 diffusion depends on the relative humidity (RH); it is most rapid between 65 and 75 percent ambient RH.

Carbonic acid then reacts with the hydrants—such as solid calcium hydroxide, calcium silicate hydrate (C-S-H) gel, and alkali/calcium ions in pore solutions—to form carbonate. Generally, calcium hydroxide has the highest concentration in Portland cement concretes and mortars.

Both mortar and CMUs, being more porous than cast-in-place concrete, experience higher rates of carbonation. In dense concrete, for example, penetration may be less than 20 mm (0.78 in.) after 50 years. With the mortar in the joints of masonry structures, indicator tests have demonstrated carbonation of a 10 mm (0.3 in.) thick by 90 mm (3.5 in.) deep mortar joint is substantially complete after less than a decade.

A recent study by the Concrete Masonry and Hardscapes Association (CMHA) for ASTM discovered that a 198 mm (7.8 in.) concrete block will be 25 percent fully carbonated within 28 days of manufacture and 49 percent within

26 weeks of manufacture (Figure 4a and 4b).4 Although current life cycle analysis (LCA) does not account for carbon sequestration of concrete masonry products due to weathering carbonation in the GWP value, it will likely be included in the near future once more accurate methods of estimating weathering carbon sequestration by concrete masonry products are established.