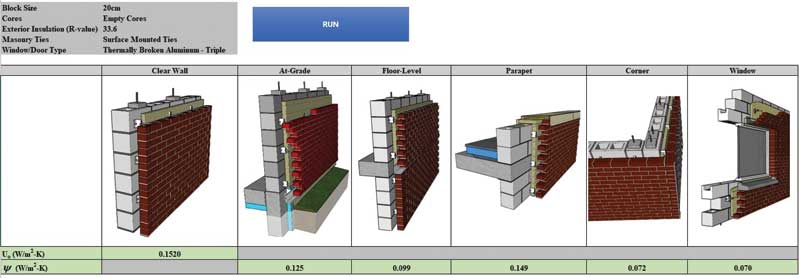

In partnership with the University of Alberta, thermal values were obtained and placed into a spreadsheet application (Figure 9) that captures items not currently found in the online thermal catalog and increase the accuracy of thermal models for wall assemblies using CMUs. This masonry thermal catalog application can be used to complement the existing comprehensive online thermal catalog.

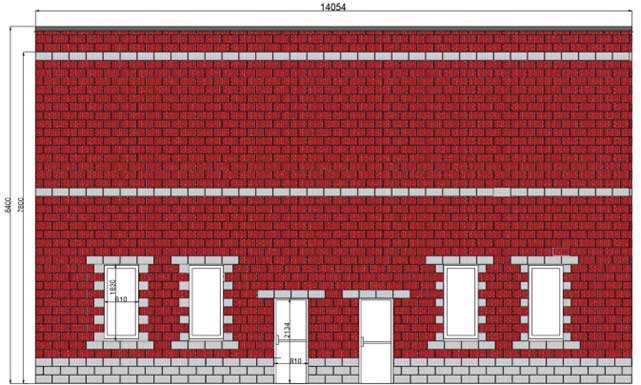

Another method to improve thermal efficiency in the envelope is to reduce the number of windows and doors (glazing) and increase the amount of opaque wall, resulting in a decrease in the fenestration and door-to-wall ratio (FWDR). It is easiest to illustrate achieving a net-zero energy building for the opaque wall required for passive house standards with an example of a single elevation of a brick veneer with a CMU backing on a two-story warehouse/office. Figure 10 provides a 3D rendering of a hypothetical two-story warehouse/office building located in Calgary, Alberta.

Figure 11 provides the 2D details for the front elevation of the building. The relevant dimensions of the building are as follows: 14 m (46 ft) long, 7.8 m (25 ft) tall at the roof transition, with a 0.6 m (1.9 ft) parapet. There are four 1.83 x 0.810 m (6 x 2.6 ft) windows and two 2.13 x 0.810 m (7 x 2.6 ft) doors on the front elevation.

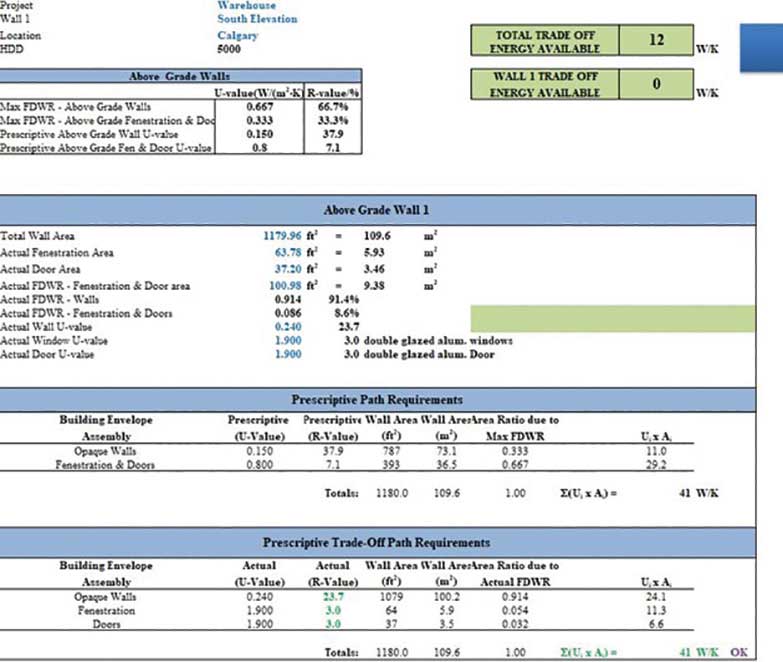

To achieve passive house (net-zero energy building) requirements, Passive House Canada recommends a target of 0.15 W/m2 K (R-37.8) for opaque walls and 0.8 W/m2 K (R-7.1) for windows and doors.3

When using a concrete block with a brick veneer, two steps are required. The first step is a reduction in the opaque wall insulation demand for using a low glazing ratio that is typically associated with low-rise masonry warehouse and light industrial buildings.

Using a low glazing ratio benefits the overall performance of the wall system. The thermal requirements for fenestration and doors, even by Passive House standards, are five times worse than that of opaque walls. Therefore, a fully opaque wall with a lower insulation value, say R-22, will typically have an equivalent or better performance than a wall that has R-37.8 (0.8 W/m2 K). This applies to an opaque assembly at the maximum 33 percent FWDR permitted (based on the Heating Degree Days [HDD]) in many parts of Canada when using fenestration and doors at R-7.1(0.15 W/m2 K).

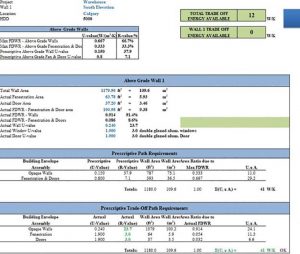

There is a prescriptive trade-off method developed by the National Energy Code for Buildings (NECB)5 that captures this and allows a proposed assembly to be designed and constructed—but only if an equivalent or less amount of heat energy is lost by the proposed assembly than the prescriptive requirements for an elevation of the same dimensions at maximum permitted FWDR. Figure 12 illustrates the calculations using the NECB prescriptive trade-off method, but with the net-zero targets of 0.15 W/m2 K (R-37.8) and 0.8 W/m2 K (R7.1) for opaque walls and for windows and doors respectively on the front elevation in Figure 11. The result of the calculation is a wall that loses 41 W/K of heat energy, which matches the prescriptive requirements for a 33 percent FWDR wall with R-7 and R-38 opaque walls, but used R-3 triple glazed thermally broken windows and doors and requires only R-23.7 from the opaque walls.