by Bill DuBois, CSI, CCS, AIA, and Chris Bennett, CSI, Assoc. AIA

Construction documents need to be clear, concise, correct, and complete—but is this enough to fend off the twists and turns of executing the contract for construction? One may begin with the very best in design intent, but it is the responsibility of the entire project team to understand and adhere to this in order for it to become a reality. Too often, some of the team members will alter the intended design to accommodate their own business advantage. Construction administration is critical to ensure the design intent is achieved.

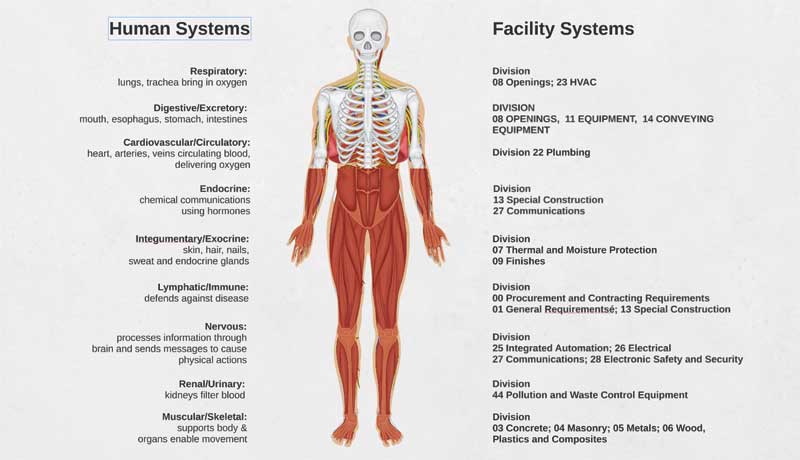

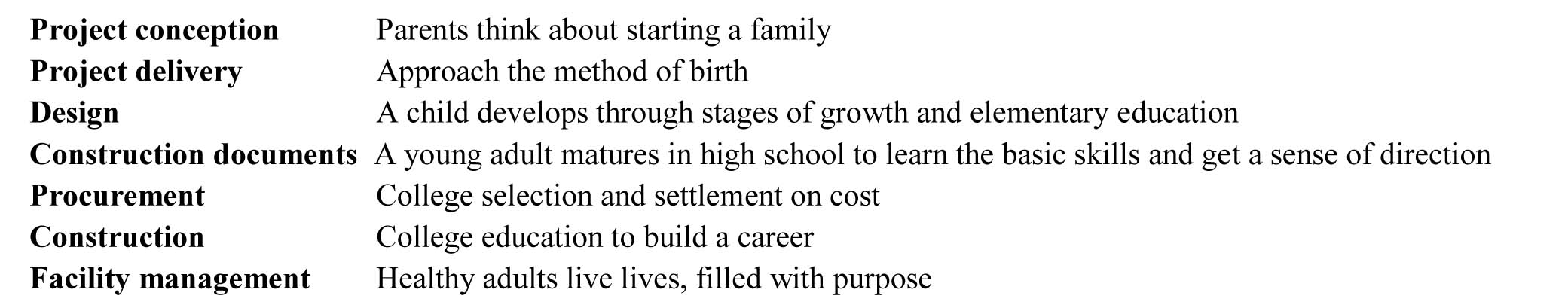

To demonstrate the humanistic aspect of construction, this article makes an analogy between two complex assemblies of infrastructure—the human body and a constructed facility. Both exist to support life, have a life cycle of their own, and require planning and nurturing before they can take on productive roles. With a little creative, flexible thinking, Figure 1 shows the comparisons. Figure 2 offers another analogy—CSI’s facility life cycle process and a possible life cycle of a human being.

While the authors could go on examining how buildings compare to biology, that is another story being developed by the field of biomimicry. Instead, this article focuses on the facility’s design intent around Division 03, one of the “muscular/skeletal” systems. We want our creations to be strong, healthy, and live long, prosperous lives. This requires having a strong foundation of bones and muscles through which to carry us. Concrete and concrete flooring systems are essential in maintaining strong facility life.

Concrete thinking

One of the unforeseen gifts of the great recession was the realization of how poorly concrete is actually built. With the popularity of polished concrete floors growing, finishes like carpeting, tiles, and epoxies were removed in many buildings—in frequent cases, this enabled project teams to see right underneath the skin, the building was an infected, unhealthy environment. Suddenly, questions arose:

- Why is this floor so undulated/wavy?

- What is causing this curling?

- Why, despite all the products injected into the slab, is there random cracking, crazing, and delamination?

- Is there a way to stop efflorescence, blushing, and other types of extreme discoloration?

- Why do we have buildings with critical concrete failure that are only a decade or so old?

Many ideas have been offered to resolve these problems, but they have proved only to be temporary solutions, merely addressing the symptoms of a chronically unhealthy system and not the root cause. To make matters worse, industries have sprouted up around creating such stopgaps, taking away the incentive for suppliers and contractors to meet a healthy, sustainable design intent.

One of the first places to see these problems was flooring, which takes the most physical abuse in most spaces. With the help of gravity, it collects the most dirt and debris, requiring routine maintenance. The traffic atop the slab compounds the abuse.

Concrete should be able to address these issues for flooring. It is durable and long lasting (when done correctly) and there are the additional aesthetic benefits that should also be built to last. Concrete can be dyed, stained, integrally colored, textured, or polished. Broken glass, seashells, marble chips, and other media can also be introduced into the concrete matrix to expand the visual possibilities.

However, for a concrete floor to be as maintenance-friendly as possible and maintain its original appearance, it must be non-absorptive to resist moisture, dirt, and movement from volume changes. A facility cannot maintain its clean and healthy status when the floor is dirty or unable to be resilient to abuse.

This is a very interesting article. I came across it on a linked-in post. I would like to make a few comments in regards to this:

A. The standards that you talk about in regards testing for results of a polished floor seem to entirely different than the ones proposed by Concrete Polishing Council (part of the American Society of Concrete Contractors). Maybe their needs to be some collaboration to really discuss which is the better way to specify and test for results.

B. I have attended a seminar at the World of Concrete that talked about the slab being the canvas that the concrete polisher uses. It went into the details of a concrete slab from mix design to placing techniques as it relates to polishing. I would recommend it to anyone who wants more in depth knowledge on the subject.

C. Where we see the most problems in concrete slabs on grade is incompetence in production of the specifications and managing the owners expectations. Concrete slabs today are too often being specified by engineers or architects and built by contractors who have little or no experience in that realm of SOG construction. They don’t understand that their are experts who understand the behavior of slabs on grade and what is required to deliver a quality slab. Today the use of nano-silica, high dosed macro synthetic fibers, and/or steel fibers, and other admixtures along with placing and finishing technology changes the entire behavior of slabs on grade. This is compounded when the finished surface is going to be a polished slab (especially a decorative slab).