Healthy Concrete Systems: Defending design intent

by Katie Daniel | October 4, 2016 10:00 am

by Bill DuBois, CSI, CCS, AIA, and Chris Bennett, CSI, Assoc. AIA

Construction documents need to be clear, concise, correct, and complete—but is this enough to fend off the twists and turns of executing the contract for construction? One may begin with the very best in design intent, but it is the responsibility of the entire project team to understand and adhere to this in order for it to become a reality. Too often, some of the team members will alter the intended design to accommodate their own business advantage. Construction administration is critical to ensure the design intent is achieved.

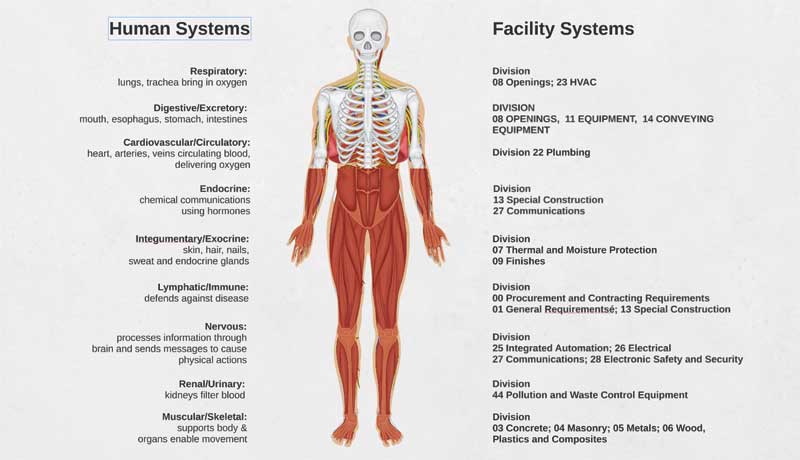

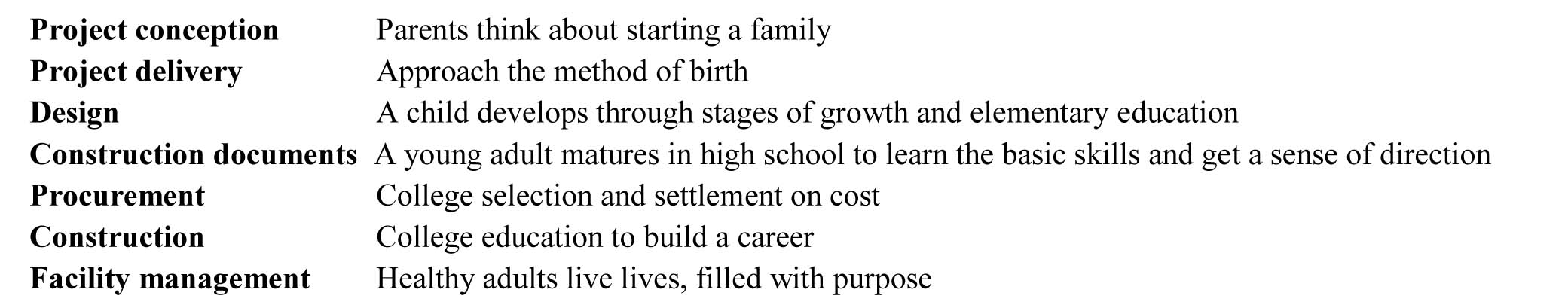

To demonstrate the humanistic aspect of construction, this article makes an analogy between two complex assemblies of infrastructure—the human body and a constructed facility. Both exist to support life, have a life cycle of their own, and require planning and nurturing before they can take on productive roles. With a little creative, flexible thinking, Figure 1 shows the comparisons. Figure 2 offers another analogy—CSI’s facility life cycle process and a possible life cycle of a human being.

While the authors could go on examining how buildings compare to biology, that is another story being developed by the field of biomimicry. Instead, this article focuses on the facility’s design intent around Division 03, one of the “muscular/skeletal” systems. We want our creations to be strong, healthy, and live long, prosperous lives. This requires having a strong foundation of bones and muscles through which to carry us. Concrete and concrete flooring systems are essential in maintaining strong facility life.

Concrete thinking

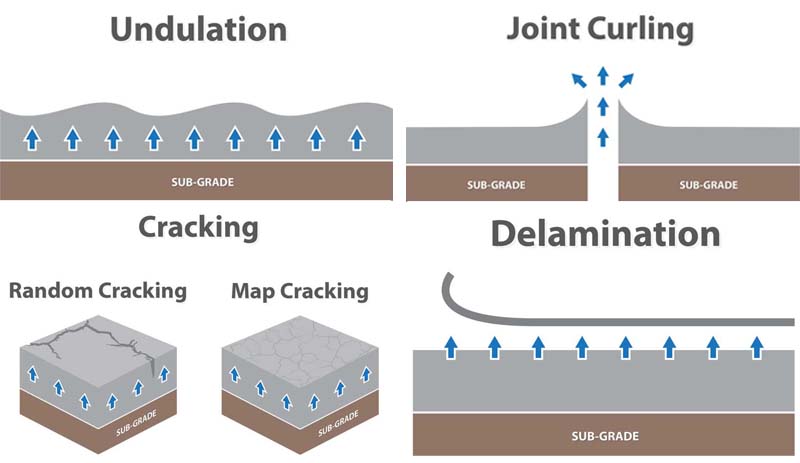

One of the unforeseen gifts of the great recession was the realization of how poorly concrete is actually built. With the popularity of polished concrete floors growing, finishes like carpeting, tiles, and epoxies were removed in many buildings—in frequent cases, this enabled project teams to see right underneath the skin, the building was an infected, unhealthy environment. Suddenly, questions arose:

- Why is this floor so undulated/wavy?

- What is causing this curling?

- Why, despite all the products injected into the slab, is there random cracking, crazing, and delamination?

- Is there a way to stop efflorescence, blushing, and other types of extreme discoloration?

- Why do we have buildings with critical concrete failure that are only a decade or so old?

Many ideas have been offered to resolve these problems, but they have proved only to be temporary solutions, merely addressing the symptoms of a chronically unhealthy system and not the root cause. To make matters worse, industries have sprouted up around creating such stopgaps, taking away the incentive for suppliers and contractors to meet a healthy, sustainable design intent.

One of the first places to see these problems was flooring, which takes the most physical abuse in most spaces. With the help of gravity, it collects the most dirt and debris, requiring routine maintenance. The traffic atop the slab compounds the abuse.

Concrete should be able to address these issues for flooring. It is durable and long lasting (when done correctly) and there are the additional aesthetic benefits that should also be built to last. Concrete can be dyed, stained, integrally colored, textured, or polished. Broken glass, seashells, marble chips, and other media can also be introduced into the concrete matrix to expand the visual possibilities.

However, for a concrete floor to be as maintenance-friendly as possible and maintain its original appearance, it must be non-absorptive to resist moisture, dirt, and movement from volume changes. A facility cannot maintain its clean and healthy status when the floor is dirty or unable to be resilient to abuse.

Photos © Tara Imani

Verification and definitions (or lack thereof)

The Ancient Romans figured out how to make concrete resilient and sustainable—the evidence remains standing today (Figure 3). However, specifying the physical properties of exposed concrete flooring seems to remain a nebulous challenge. This is primarily because the industry has not had a clear way of quantifying the exact definition of polished concrete.

According to the International Polished Concrete Institute (IPCI):

Polished concrete is a process which enhances the natural beauty of existing concrete by hardening and applying a sheen to the concrete. There are two primary methods to create this sheen: Topical or Mechanical.

However, this can be vague. Traditionally, it has been entirely up to the contractor to deliver a shiny floor by means of a prescribed process. The question is whether it was what the owner or architect expected. Who is to argue, given a vague specification that prescribes a process rather than a quantifiable and verifiable result?

Ensuring the intent

The goal is a floor that is aesthetically pleasing, durable, easily maintainable, slip-resistant, sustainable, and resilient. Taking the steps explored in the following section, these attributes can be established by way of the specifications and verified in the field.

Aesthetically pleasing

It takes a good slab that has been placed correctly to get controlled results. Flatness is important—one will not be able to get an even and consistent appearance if the slab is wavy and improperly cured. This is particularly true when a ‘cream’ finish with minimal aggregate exposure is desired.

Aggressive grinding, at additional expense, to expose more aggregate can even out the appearance, but does not guarantee the desired look. In fact, it forces the owner to accept another level of aggregate exposure. Sheen is also an aesthetic that can be achieved ranging from a dull/matte finish to a highly polished/mirror-like glossy finish. Of course, the more shiny the finish, the more noticeable the flatness. However, it is important to keep in mind ‘shiny’ is not the definition of polished (or refined) concrete; in many cases, a highly reflective finish is inappropriate. For example, a highly reflective floor in a toilet stall compromises privacy between the toilet compartments.

By specifying the industry standard for floor flatness and floor levelness, ASTM E1155, Standard Test Method for Determining FF Floor Flatness and FL Floor Levelness Numbers, an appropriate degree of flatness may be specified to suit the function and aesthetic of a space. Higher flatness/levelness numbers may only be achieved by skilled, certified installers.

The first method of specifying exposed concrete surfaces was based on ‘grit levels,’ and then measuring the light reflected off the floor. However, this proved too subjective and often unintentionally distorted original design intent. By instead measuring the refinement of the concrete itself using surface texture grades (STG) and roughness averages (Ra), one creates a common language for specifiers, contractors and the entire project team. This surface texture corresponds to the finished sheen of the concrete floor without the disguise of an applied surface sealer. Rather than using older subjective standards, both the design decision-maker and contractor now have a familiar, quantifiable language to not only express design intent, but also ensure it has been met. (Surface roughness is the science of measuring the physical texture of a surface. An STG is a specific measurement of the physical texture describing the roughness characteristics of the surface. The Ra, sometimes called roughness average, is an integral of the absolute value of the roughness profile; it is measured in either microinch (µin) or micrometer (µm). While used for many decades in the steel, glass, and plastic industries, a growing number of specifiers and contractors are using the following Ra measurements to describe physical refinement of concrete surfaces and quantify design intent: Matte (30 µin) Semi-gloss (16 µin) Glossy (6 µin) for the United States, and (0.76 µm) Semi-gloss (0.41 µm) Glossy (0.15 µm) for the rest of the world.)

Durable

A floor material needs to be able to withstand wear, pressure, and damage—concrete can do all this, but only if done correctly. All floor materials will eventually show signs of wear given an extensive amount of traffic, but a hard and dense surface is essential to keeping this minimal. When the top surface of concrete is densified by way of microscopic crystallization, the upper portion of the slab becomes extremely hard and abrasion-resistant. Sealers or other temporary topical finishes are very soft, and will scratch and wear away quite easily.

Maintainable

Densification of the surface also contributes to concrete’s ability to reject dirt and liquids. Produced correctly, concrete is inherently resistant to contaminants. What stays on the surface is easily removed. Spills that do not have a chance to get into the pores beneath the surface do not get the chance to become permanent.

Therefore, routine maintenance becomes much easier and more likely to occur regularly. Rather than create slabs needing constant reapplication of coatings or sealers that mitigate moisture and vapor transmission, one should design a slab that performs so the requirements for the material and labor are reduced.

Slip-resistant

While the expectation may be a smooth surface is slippery, this is not necessarily the case—both Occupational Safety and Health Administration (OSHA) and National Safety Council (NSC) list uneven walking surfaces as a bigger cause of trip hazards. Further, a refined concrete surface without sealers, waxes, and cleaning surfactants provides

a safe dynamic coefficient of friction (DCOF). With the growing numbers of baby boomers reaching retirement, it is critically important design/construction professionals raise the standards for both flatness and levelness.

Sustainable

As a result of the combined characteristics mentioned in the preceding sections, a concrete slab designed to keep out moisture will provide a very long-lasting flooring solution requiring minimal maintenance to keep its natural beauty throughout the entire life cycle of the facility (Figure 4). If in case the floor ever does become covered with some other surface-applied finish, it has a much better chance of recovery when the applied flooring has worn out and needs to be removed.

An added benefit of concrete that naturally maintains its volume is its natural moisture mitigation attributes. This is a huge cost saving advantage where there will be installation of moisture-sensitive floorcoverings such as tile, carpet, or epoxy coatings.

Images courtesy Tao Group

Resilient

In the past, the industry has counted on coatings, sealers, and epoxies to keep moisture in a slab. However, it is possible to create concrete naturally exceeding ASTM E96, Standard Test Methods for Water Vapor Transmission of Materials, and ASTM C309, Standard Specification for Liquid Membrane-forming Compounds for Curing Concrete. This can be achieved through use of nano-infused cements, hydro-cements, and other similar technologies that mimic ancient Roman concrete in performance, but without the long cure times.

By controlling volume loss, both structural and aesthetic concrete problems diminish over the lifetime of the facility. In Bill Gate’s Fortune review of Robert Gordon’s The Rise and Fall of American Growth[1], he talks about new “super cement” that will allow us to “build infrastructure that lasts 10 times as long as the cement rebar approach.” Nano-infused cements, hydro-cements, and other similar based technologies are fundamental elements of this technology; it also diminishes unwanted elements such as curling, floor undulation, cracking, and slab discoloration.

Ensuring design intent

How can someone be assured his or her design intentions are being met? The preference would be not to have to depend on subjective opinions that tend to differ among the perspectives of the owner, architect, and contractor. Instead, the goal is to clearly define quantifiably what is to be achieved as a contract requirement in the specifications. Not until the work has been tested and verified to have met specific requirements can it be determined to be acceptable.

A performance specification can avoid the visual inspection of what looks good at the time of substantial completion—only to wear off in a relatively short period, requiring costly reapplication of sealers.

Up until now, some of the concrete attributes mentioned in this article have been extremely difficult to achieve. An excellent concrete slab or polished concrete floor is the result of a skilled trade applying proper materials. Unless both are carefully identified in the contract documents, one will most likely come upon unsatisfactory results that do not meet expectations. Unfortunately, it has been all too often that at the very end of construction, with extreme pressure for impending occupancy, the owner is forced into accepting results neither expected nor desired. This is a tough pill to swallow when money is being exchanged for dissatisfaction just to get occupancy of the facility on time. Even less palatable is the ongoing additional expense that will be incurred to maintain a non-sustainable floor over the life of the building.

In order to avoid this dismal picture, it is extremely important to take all the following steps throughout the construction process:

- The owner team must clearly understand the design intent that is attainable and can be achieved in order to protect their dollar investment.

- The design team must understand what is achievable and confirm the design intent with the client. The team must document all the requirements in the construction documents and defend the design intent throughout the entire construction process. One should beware product substitutions that claim to be the same as what is specified. Shop drawing reviews are critical to verify design intent will be met.

- The construction team must be aware of the desired outcome of the documented design intent. This includes third-party qualified subcontractors that are certified and capable of producing the specified requirements. This must be confirmed during contract procurement phase to avoid the all-too common confrontation that occurs when it was overlooked and not included in the contract sum.

- Finally, the supplier team must be responsible for supplying the products and materials that are capable of achieving the intended design. Again, all too often, some suppliers will try to suggest their products are the same or better than what was chosen and specified based on performance, not just appearance. Substitutions must only be considered when they have specific test results showing proven performance capabilities satisfying the specified requirements.

Conclusion

Polished concrete has recently become a very popular design choice among interior designers due to its sustainable qualities and long-lasting aesthetic. While polished concrete is more expensive than applied coverings in terms of first costs, it may be one of the most economical choices over the life of a building. It is important the entire project team has a clear understanding of what is meant by ‘polished concrete,’ and then take the necessary steps to ensure the design intent is being met.

In some ways, construction professionals are the parents and guardians of their offspring (that is, the buildings they create). To this day, we cherish some of the ancient concrete structures built by the Roman Empire and have survived millennia. It is time again to make outstanding achievements in construction that will endure as economically viable, sustainable structures with durable, long-lasting, useful lives.

Bill DuBois, CSI, CCS, AIA, is the vice president of specifications with Tao Group LLC, a firm that assists building teams to achieve concrete installations meeting project expectations. He has 30 years of specification experience at major architectural firms and has recently chosen to pursue the next step of his architectural career at elevating a segment of the construction industry that has been an architectural specifier’s challenge. DuBois can be reached at bill_dubois@taogroupsolutions.com[2].

Chris Bennett, CSI, Assoc. AIA, is the vice president of business development at Tao Group. He is also involved with facilitating the popular construction education series, Praxis Live Events. Bennett previously led specifications efforts at Husqvarna Construction Products, and served as a Mandarin Chinese cryptolinguist on active duty for the United States Navy. He can be contacted at christopher.bennett@taogroupsolutions.com[3].

- The Rise and Fall of American Growth: http://www.fortune.com/2016/07/27/bill-gates-robert-gordon

- bill_dubois@taogroupsolutions.com: mailto:bill_dubois@taogroupsolutions.com

- christopher.bennett@taogroupsolutions.com: mailto:christopher.bennett@taogroupsolutions.com

Source URL: https://www.constructionspecifier.com/healthy-concrete-systems-defending-design-intent/