AWRBs are systems

AWRBs are systems

Air barriers are required under the IECC for all buildings, to prevent uncontrolled airflow through the building enclosure. Where framed construction is used, the International Building Code (IBC) requires the use of a water-resistive barrier (WRB), which is intended to prevent the passage of liquid water into the wall. In most cases, these two functions are combined, resulting in an air- and water-resistive barrier (AWRB) that manages the flow of water in liquid form and in the form of humidity.

While AWRBs are code requirements; permeance is a design decision. Permeability is a membrane characteristic and those concerned about moisture vapor permeation through the AWRB can specify a vapor impermeable AWRB. Conversely, those who wish to permit incidental moisture that may find its way behind the AWRB to dry out can specify a vapor permeable AWRB as well.

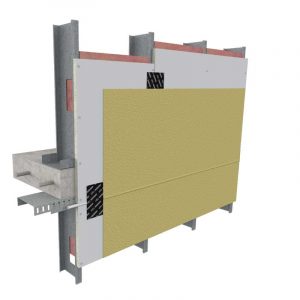

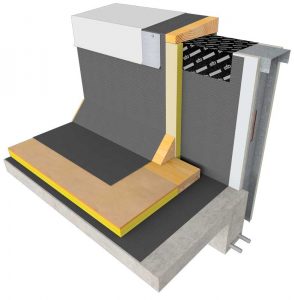

The AWRB system used for walls is a subsystem of the overall building air barrier, which encompasses roof and below-grade components. As such, the wall AWRB must be compatible with roofing and foundation sealing. However, wall AWRBs are particularly complex because they must manage challenging situations such as movement joints, flashing, penetrations, connections to windows and doors, and substrate transitions. They must also function as a WRB where framed construction is used and applied.

Wall AWRBs accomplish this by incorporating detail components that are specifically designed and tested for these specialized functions. Self-adhered membranes, sealants, and liquid flashing membranes are examples of these components. They provide a continuous seal that is durable and airtight, and are compatible with the rest of the AWRB. It is the combination of the air barrier components and the air barrier membrane that defines a wall AWRB system. These systems are typically installed by one installation contractor.

Specifiers take the lead

The first step toward realizing a high-performance AWRB system is design and specification. Specifying one continuous AWRB system for all walls on a building solves many problems before they occur.

Unfortunately, the AWRB portion of wall design has historically been a function of building aesthetics. Claddings selected for their appearance are often specified along with a supporting wall assembly that may include an AWRB. Where more than one cladding appearance is specified, different AWRB systems may be called out. This creates a situation where multiple air barrier systems are used. In extreme cases, mechanically fastened sheet goods have been installed adjacent to fluid-applied systems.

Multiple AWRB systems are typically parceled out to a number of installers, none of whom are responsible for the transition from one AWRB system to another. Leakage or incompatibility between adjacent systems compromises both systems and the entire building. The net result is greater air leakage and resulting effects on energy efficiency and sustainability. It also adds cost to the project. For these reasons, one AWRB system should be specified on all walls.