Photo © Tracy Myers

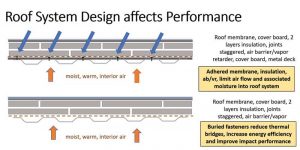

Studies have been performed to evaluate the puncture resistance of single-ply thermoplastic membranes as well as ice ball impact testing of heat-aged and non-heat-aged TPO membranes by Sarang Bhawalkar, Tammy Yang, and Thomas J. Taylor, who work for a roofing manufacturer (read “Puncture Resistance of Thermoplastic Single-Ply Roofing Membranes” by Sarang Bhawalkar and Thomas J. Taylor; “Understanding the Ice Ball Resistance of TPO Membranes;” and “Ice Ball Impact Resistance of Heat-Aged TPO Roofing Membranes” by Sarang Bhawalkar, Tammy Yang, and Thomas J. Taylor). While impact-testing may not indicate a product’s in-situ performance when subject to hail impact, it does provide performance testing information that can be considered by the roof designer (Consult “Concerns with Impact Testing” by Mark Graham). These studies have found:

- ice ball impacts at fasteners always punctured the

roof membrane; - the best-performing systems were fully adhered;

- fleece-back membranes performed better than smooth-backed ones;

- high-density ISO board performed better than gypsum; and

- roofing systems incorporating a cover board performed better than those without one.

Protected membrane roofing (PMR) assemblies, also referred to as inverted roof membrane assemblies (IRMA), are also an option for increased durability since the roofing membrane is covered and protected from damage. Green and blue roofs can be considered PMR or IRMA roofs.

Roof edge

As mentioned earlier, the roof edge is one of the most vulnerable points on the roof. Section 1504.5 of IBC requires low-slope edge securement to be “designed and installed for wind loads per Chapter 16 and tested for resistance per test methods RE-1, RE-2, and RE-3 of ANSI/SPRI ES-1, except basic design wind speed, V, shall be determined from Figures 1609.3(1) through 1609.3(8) as applicable.”

The ANSI/SPRI/FM 4435 ES-1 2017, Test Standard for Edge Systems Used with Low Slope Roofing Systems, is the latest version of the standard adopted as part of 2018 IBC. It provides the “basic requirements only for resistance testing for roof edge systems under simulated wind load conditions.” The standard “applies to low-slope roof systems, with low-slope defined here as roofs having a slope less than or equal to 9.5 degrees (2:12).”

There are a variety of sources for ES-1-tested products. Pre-manufactured systems may have been pre-tested for compliance. The National Roofing Contractors Association (NRCA) and the Sheet Metal and Air Conditioning Contractors National Association, Inc. (SMACNA) include roof edge details that have been tested for conformance with the standard (see the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) Technical Resources Bulletin on “STRI Wind Uplift Testing”). To increase the durability of the roof edge, specify a continuous cleat and increase the thickness/gauge of the cleat. Make sure to attach the coping and blocking to the underlying substrate securely.

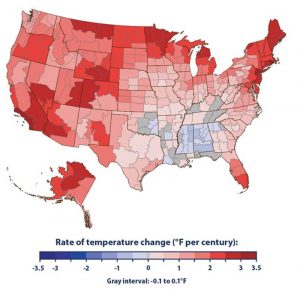

Image © NOAA, 2016. National Centers for Environmental Information, Accessed February 2016

Green roofs

Green roofs can help to mitigate climate change effects on urban environments by reducing and slowing runoff into aging combined sewer systems as well as lowering the roof temperature, thus helping to minimize the urban heat island effect. The vegetative overburden in these systems also protects the underlying membrane. Green roofs could be a good option for locations with impact risks such as hail.

Blue roofs

Blue roofs also control the amount of water into local sewer systems through the delayed discharge of water. They reduce the peak stormwater impact on wastewater treatment plants. Vegetative components can be integrated into these as well. Similar to green roofs, the membrane is protected.

Cool roofs

IECC provides roof solar reflectance (how much solar energy is reflected by the membrane) and emittance requirements (how much absorbed heat is radiated back into the atmosphere) for low-slope roofs over conditioned spaces in Climate Zones 1 to 3. Studies have also shown cool roofs provide energy savings in all climates when the cost of electrical demand charges are taken into account (read “Cool Roof Use in Commercial Buildings in the United States: An Energy Cost Analysis” by Thomas J. Taylor and Christian Hartwig).

Cool roofs are not the solution in every case, as each project and its location must be considered individually. Existing wood deck roof systems can pose certain risks when converting to a highly reflective membrane, and there are elevated sources of interior moisture (read the article “Practical Application of Hygrothermal Modeling of West Coast Wood Deck Systems” by A.O. Desjarlais, H. Hardy Pierce, W. Woodring, and S. Pallin). Due to the lower roof temperature on a cool roof, the self-drying aspects of dark roof membranes no longer apply. Additionally, there is a risk of condensation.

Photovoltaics on the roof

In the case of photovoltaic (PV) installations, it is crucial to consider the useful life of the equipment relative to the roof system and to carefully review all attachment points for both structural integrity as well as adequate waterproof detailing. Utilizing energy storage in conjunction with power generation can provide backup power during grid interruption.

Case study

Portland-based Lever Architecture designed the renovation and expansion of the Nature Conservancy’s Oregon headquarters. As sustainability was integral to the project design, the team decided to maintain and renovate the original 1970’s building.

The roof of the Oregon Conservation Center building comprises two systems. The first is composed of an 80-mil TPO membrane, a 13-mm (1/2-in.) thick glass mat-faced, moisture-resistant gypsum cover board, 100 mm (4 in.) of closed-cell polyisocyanurate (ISO) foam, a vapor retarder, and roof sheathing on the existing, sloped roof structure of the three-story portion of the building. This particular roofing type was selected for its high albedo, longevity, and durability. It is designed as a cool roof system featuring a grid-tied PV system that offsets 25 percent of the building’s annual energy usage. The PV system is also designed for connection to a battery storage system to provide off-grid power during outages.

The second roof system is located on the single-story building addition, and features an intensive green roof as well as a roof deck built with Forest Stewardship Council (FSC)-certified cedar decking sourced from the Nature Conservancy’s Ellsworth Creek Preserve in Willapa Bay, Washington. The roof structure for the addition is made from five-ply and seven-ply FSC-certified cross-laminated timber (CLT). The green roof features soil depths varying from 150 mm (6 in.) to 1 m (3 ft), and includes vegetation and plantings native to the Rowena Plateau in Oregon’s Columbia Gorge. The waterproofing system below both the green roof and the roof deck is a reinforced, hot-rubberized asphalt (HRA) membrane with an integrated leak-detection system. The roof assembly includes 100 mm of extruded polystyrene (XPS) board insulation above the HRA membrane system. The cedar roof deck is supported on adjustable pedestals that bear on the rigid insulation. The HRA membrane system was selected for its high performance and integrated leak detection system.

Excellent breakdown of high-performance roofing strategies! Informative content with practical insights. Thank you for enhancing our understanding of roofing dynamics.