In terms of the door operator itself, some manufacturers describe their products as “exterior rated,” but beware of this term, as it does not necessarily equate to “waterproof.” “Exterior-rated” often means the device can operate in exterior exposure. However, the device may be riddled with holes for wires and anchorages. The device may be appropriate for exterior use, but if water can flow through the product, it certainly is not “waterproof.”

Waterproofing door operators

Operating the door or keeping the door secure against wind creates a significant load that must transfer from the door, through the floor operator assembly, and into the structure to keep the operator and door stable in service. The waterproofing system typically crosses this load transfer path. If the waterproofing, door, and structural design are not coordinated

well in advance, the waterproofing will most likely be compromised.

Typically, door operator manufacturers are silent on the exact methodology of how the operator attaches to the structure. Product drawings often show holes or slots in the perimeter of the operator housing to accommodate securement,

but most manufacturers decline to take on the responsibility of designing

the anchorage itself. Manufacturer’s shop drawings often simply state “ANCHORAGE BY OTHERS,” leaving the responsibility to project designers or installers. Where plaza waterproofing membranes are directly underneath a door operator, direct post-installed fasteners, such as screws, often result in blind and unsealed holes in the waterproofing. Screws auger through waterproofing, often concealed by shims or the mechanism itself. These untreated holes can void the warranty of the waterproofing system, but more importantly, can lead to leaks. With proper coordination and planning, project teams can provide sufficient vertical space in the detailing of the anchorage to result in both a sufficiently anchored closer and one that is also sealed in a watertight manner at penetrations.

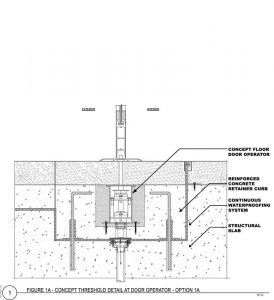

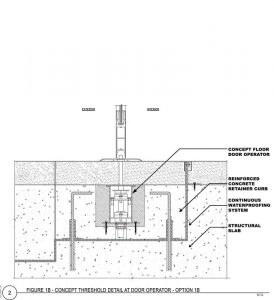

Typically, a pre-installed bridge is necessary to transfer the load from the operator to the structure without impacting the operator’s stability or the integrity of the waterproofing. A bridge can be achieved by extending the waterproofing under a reinforced concrete retainer curb (Figures 2A and 2B). The curb, anchored with dowels, is installed after the waterproofing is installed. This sequence allows waterproofing to be bonded to a stable penetration. Dowels are preferable to epoxy-set, all-thread rods. The dowels provide a smoother surface than thread rods, which force waterproofing to bridge and seal deep into the thread grooves.

Thanks for the well written and helpful article Dan and Matt

This article on waterproofing in-floor door operators is a must read for anyone involved in construction and waterproofing. The detailed steps and considerations it outlines ensure both the functionality and longevity of door operators in wet environments. It’s a valuable resource for professionals aiming to achieve robust waterproofing solutions.