Impact of Advancements in Model Energy Codes: What’s the effect on insulation?

by Molly Doyle | January 17, 2014 2:26 pm

[1]

[1]by Jared O. Blum

In response to a national interest in, and policies for, conservation of energy, model energy codes are striving to advance the way commercial and residential building envelopes are insulated. The effect on how design professionals specify materials for thermal management will be substantial.

The International Code Council’s (ICC’s) 2012 International Energy Conservation Code (IECC) calls for a 30 percent increase in building energy savings as compared to the 2006 code. This represents the single largest efficiency increase in the history of the model energy code.

For walls, a continuous insulation (ci) system is featured as a solution in recent model energy codes because it effectively addresses these challenges. When it comes to commercial roofs, significant savings can be attained by upgrading insulation to provide an R-value meeting current code standards and practice.

[2]

[2]Continuous insulation in walls

In American Society of Heating, Refrigerating, and Air-conditioning Engineers (ASHRAE) 90.1-2007, Energy Standard for Buildings Except Low-rise Residential Buildings, ci is defined as:

insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.

Of course, this insulation approach is not new—it has been commonly used for many years on various types of low-slope roofing assemblies. Since 20th century construction practices were developed during periods of ample and cheap energy, its use on both residential and commercial building walls has lagged behind its energy-saving potential. This situation is changing through the emphasis of higher-performing wall assemblies in newer model energy codes. Like any construction material, continuous insulation must be properly specified to ensure its intended performance and appropriate use.

Materials: function and versatility

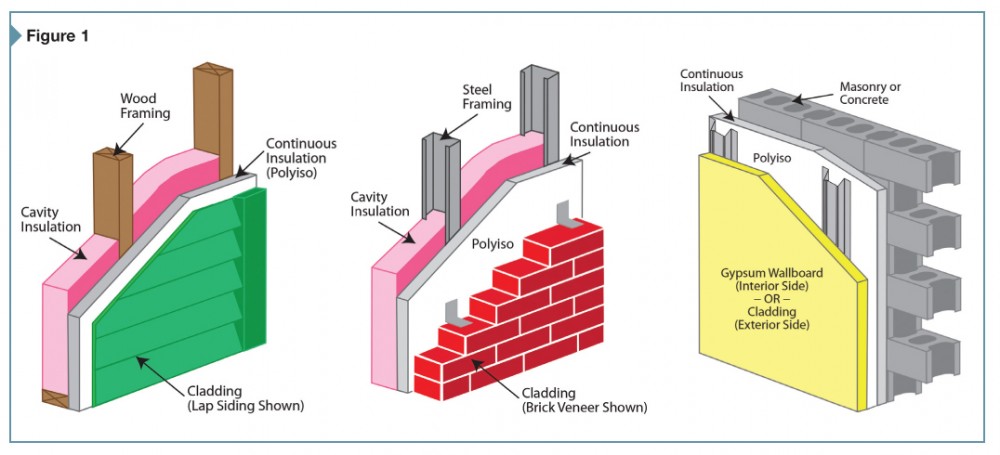

As shown in Figure 1, ci can be used with various wall structural systems and cladding materials such as:

- cement board;

- portland cement stucco;

- wood lap;

- brick veneer;

- stone; and

- vinyl siding.

In these applications, the primary function of continuous insulation is to provide code-compliant or better energy conservation performance. Additionally, properly qualified and installed ci products can serve other important functions for exterior wall assemblies, including air barriers and water-resistive barriers (WRBs). When laminated to structural materials, ci can even provide structural functions such as wall bracing. (The designer should refer to the manufacturer’s data for code-approved capabilities.)

[3]

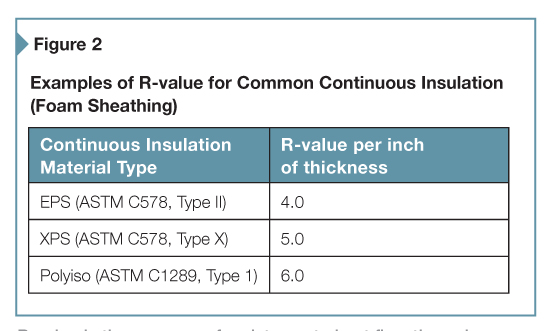

[3]Various code-compliant foam plastic insulating sheathings and other types of materials are available to address ci applications on walls. The most common foam plastic insulating sheathing products are manufactured and specified in accordance with ASTM C578, Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation, or ASTM C1289, Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board.

Material types include polyisocyanurate (polyiso) foam, expanded polystyrene (EPS), and extruded polystyrene (XPS). Each product type has different thermal properties (which affect required thickness), costs, and capabilities (Figure 2). Model building code requirements for foam plastics are found in Chapter 26 of the International Building Code (IBC).

Modern energy and building code requirements

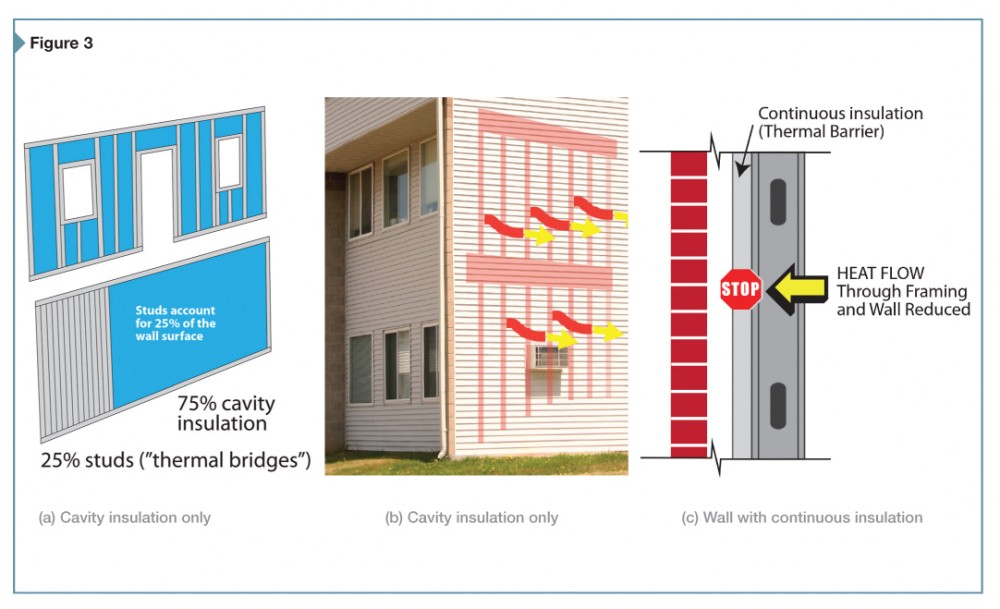

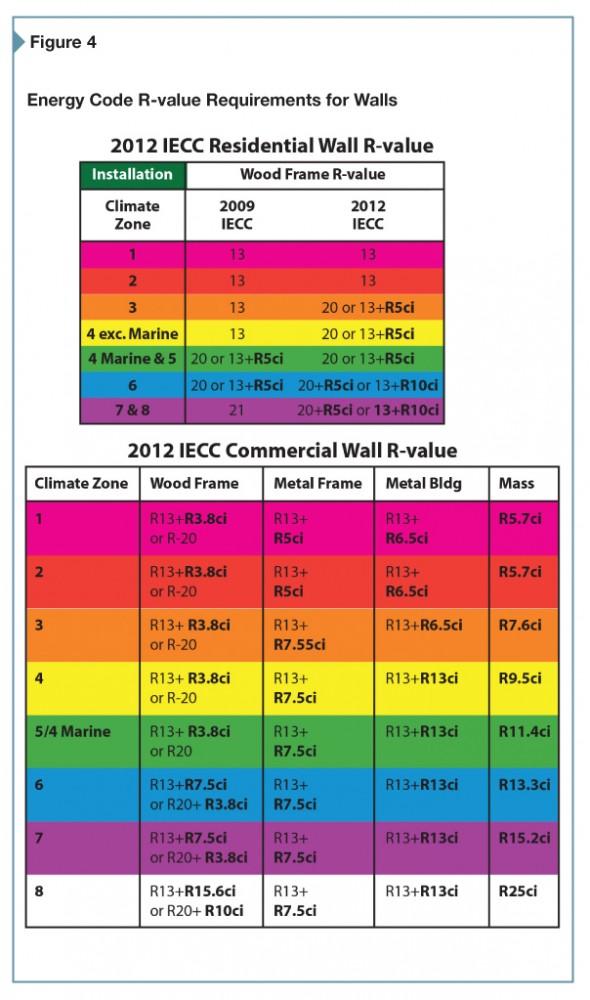

Continuous insulation provides one of the most thermally efficient ways of complying with modern energy codes. It mitigates avoidable heat loss due to thermal bridging in walls and roofs not continuously insulated (Figure 3). Modern energy code requirements for walls feature the use of continuous insulation as shown in Figure 4.

When using continuous insulation to meet or exceed the applicable energy code, certain matters of building code compliance should also be considered.

WRBs

Many ci products can be used as a water-resistive barrier behind cladding, offering water protection and thermal performance in one product. (Design professionals should refer to manufacturer installation instructions and code-compliance data.) Alternatively, WRBs can be separately applied to walls with continuous insulation.

[4]

[4]Wind pressure resistance

For code compliance guidance on wind pressure resistance of foam sheathing materials, one should refer to the American Chemistry Council’s (ACC’s) Foam Sheathing Committee Technical Evaluation Report (TER) 1006-01, Prescriptive Wind Pressure Performance of Foam Plastic Insulation used as Insulating Sheathing in Exterior Wall Covering Assemblies,1[5] along with the manufacturer’s installation instructions and design data.

It is important to verify the wind pressure resistance of other wall assembly components—including framing and siding—because testing has shown they may not be as strong as the foam sheathing material itself under wind pressure loading.

Cladding (siding) attachment

Various proprietary and standard fasteners and connection strategies can be used for attachment and support of cladding materials when installed over continuous insulation. For guidance, refer to the Foam Sheathing Committee’s Tech Matters, “Guide to Attaching Exterior Wall Coverings through Foam Sheathing to Wood or Steel Wall Framing.”

This document features solutions for direct attachment of cladding through foam sheathing and use of furring placed over and attached through foam sheathing. Both these practices minimize thermal bridging through ci due to cladding connections. Design professionals should also refer to the cladding manufacturer’s installation requirements. For example, such documentation will list minimum siding fastener size, how penetration into framing should be maintained, and whether longer fasteners are required.

[6]

[6]Fire performance

Foam plastics are held to a comprehensive set of fire performance requirements that include various types of tests and criteria to address flame spread, smoke development, and ignition protection. By far the most significant code requirement that applies to walls with continuous insulation (foam plastics) is the National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-load-bearing Wall Assemblies Containing Combustible Components. This flame spread test uses full-scale, multi-story wall assemblies.2[7] In general, compliance with NFPA 285 is not required for buildings meeting limitations for Type V construction or one- and two-family dwelling construction.

Moisture vapor retarders

It is important to ensure ci is specified together with moisture vapor retarders in such a way that moisture vapor is properly managed. Recent building code improvements (i.e. 2009 IBC Section 1405.3, Vapor Retarders) ensure adequate R-value is provided in different climates to prevent condensation by keeping walls warm (i.e. above dewpoint) and to ensure vapor retarders are used in a manner that promotes seasonal drying capability.

Energy codes and the roof

One of the best and simplest ways to achieve a high degree of energy efficiency is by increasing the levels of insulation on the roof. In fact, for long-term energy savings, the commercial roofing market provides a significant multiplier effect to accelerate energy efficiency efforts. For every new roof installed on a building, approximately three additional ones are installed on existing buildings to replace older, less energy-efficient assemblies.

More than 370 million m2 (4 billion sf) of flat roofs are retrofit annually, with untold other existing roofs waiting for their turn.3[8] If all these commercial roofs were upgraded to meet the requirements of the 2012 IECC, energy savings would be significant.

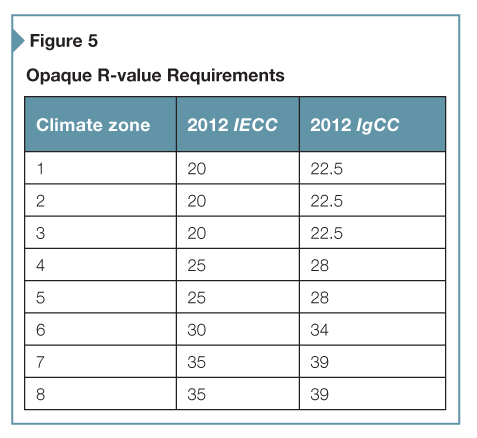

Published by Polyisocyanurate Insulation Manufacturers Association (PIMA) and the Center for Environmental Innovation in Roofing, Roof and Wall Thermal Design Guide provides information regarding the prescriptive thermal value tables in the 2012 IECC and the references to these tables in the 2012 International Green Construction Code (IgCC). The guide translates this information into simple and straightforward roof and wall R-value tables covering the most common forms of commercial opaque roof and wall construction.

For example, R-values for the 2012 IgCC and IECC for “roofs with insulation entirely above deck” are determined by reducing the overall roof assembly U-factor by 10 percent, and converting the assembly U-factor to the corresponding insulation R-value. Resultant R-values in the table (Figure 5) are rounded to the nearest 0.5 R-value.

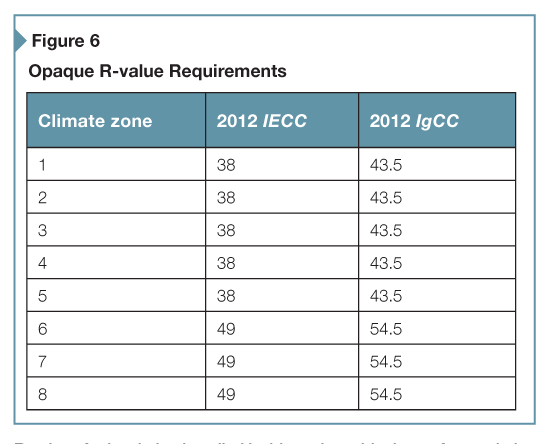

In 2013, both ICC and ASHRAE adopted language making it clear once and for all the R-value required for new building construction also applies where “the sheathing or insulation is exposed” during reroofing. For attics and other roofs, the rated R-value of insulation “is for insulation installed both inside and outside the roof or entirely inside the roof cavity.” This information can be found in Figure 6.4[9]

[10]

[10] [11]

[11]Construction detailing

It is important to provide workable and complete construction details for walls and roofs with ci to ensure a constructible and functional assembly relating to many of the topics discussed in this article. Construction details to consider include:

- envelope component attachments;

- integration of flashing and WRB;

- integration of furring (if used) around wall penetrations and flashing;

- attachment of cladding to wall framing through ci or to furring;

- details for cladding attachments through ci at inside and outside corners; and

- installation detailing per NFPA 285 tested assembly when required. Some useful detailing resources or concepts can found from various sources. Proprietary cladding systems may also include details for accommodation of continuous insulation.

The advancement of model energy codes represents another step forward in ensuring a reduction in energy consumption, which in turn helps stabilize or even decrease utility costs.

[12]

[12]Notes

1 The group’s membership includes numerous foam sheathing manufacturers, along with the ACC’s Center for the Polyurethanes Industry (CPI), EPS Molders Association (EPSMA), Extruded Polystyrene Foam Association (XPSA), and Polyisocyanurate Insulation Manufacturers Association (PIMA). For more information, visit www.foamsheathing.org[13]. (back to top[14])

2 For more information, refer to the Foam Sheathing Committee’s Tech Matters, “NFPA 285 Tested Assemblies Using Foam Sheathing,” and the specified manufacturer’s fire test data. (back to top[15])

3 This comes from a 2012 report, “Twenty-five Years of Polyiso: The Energy and Environmental Contribution of the Polyiso Insulation Industry 1987?2011” prepared by Tegnos Research for PIMA. (back to top[16])

4 Additional details on these wall and roof types, as well as others, can be found in the Roof and Wall Thermal Design Guide. Visit c.ymcdn.com/sites/www.polyiso.org/resource/resmgr/latest_news/icodesguide2012_snglpgs.pdf[17]. (back to top[18])

Jared O. Blum is the president of the Polyisocyanurate Insulation Manufacturers Association (PIMA), the Washington-based North American trade association representing manufacturers of polyiso foam insulation. He can be reached via e-mail at joblum@pima.org[19].

To read the sidebar, click here[20].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/IMG_0425-copy.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-67.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-68.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-69.jpg

- 1: #note1

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-70.jpg

- 2: #note2

- 3: #note3

- 4: #note4

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-70-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-71.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_January_2014_HR-72.jpg

- www.foamsheathing.org: http://www.foamsheathing.org

- top: #note5

- top: #note6

- top: #note7

- c.ymcdn.com/sites/www.polyiso.org/resource/resmgr/latest_news/icodesguide2012_snglpgs.pdf: http://c.ymcdn.com/sites/www.polyiso.org/resource/resmgr/latest_news/icodesguide2012_snglpgs.pdf

- top: #note8

- joblum@pima.org: mailto:%20joblum@pima.org

- here: http://www.constructionspecifier.com/masterformat/impact-of-advancements-in-model-energy-codes-the-value-of-energy-conservation/

Source URL: https://www.constructionspecifier.com/impact-of-advancements-in-model-energy-codes-whats-the-effect-on-insulation/