Improving stucco durability using moist-curing

The misting application should be increased in weather conditions with high drying potential; this includes high temperatures or wind speeds following plaster installation. It is best to shield the plaster from direct sunlight and wind exposure using wind breaks or plastic sheeting. The shield should be used in addition to surface misting, not in lieu of it.

The aim should be to maintain the plaster’s constant dark brown color for 48 hours following installation. If the plaster becomes light gray in appearance, the plaster has experienced excessive drying and will be susceptible to various failures. It is also recommended to pre-wet the surface of the first or second coat before installing the brown or finish coat; this will improve bonding between the layers and improve the scratch coat’s long-term strength gain.

Double-back method

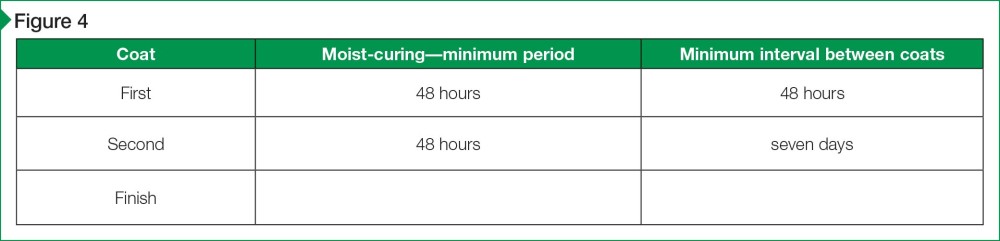

The double-back method means the application of the second (i.e. brown) coat over the scratch coat as soon as the plaster can accept the application without damage. It is the only alternate method permitted by the International Building Code (IBC) to the curing recommendations shown in Figure 4.

Data courtesy ICC

There are several benefits to utilizing the double-back method. The brown coat’s application results in the excess mix water being absorbed by the scratch coat. This improves the two layers’ bonding and encourages further hydration of the cement particles in the scratch coat, resulting in improved strength. Additionally, the second layer of plaster increases the plaster’s overall thickness, which decreases the drying potential and provides more pores to retain moisture for curing. (See Thomas C. Geary’s article “Double-back Application of Plaster,” at stuccoguru.com.)

Caution should be used when deciding to specify the double-back method, as there are conditions requiring the scratch coat’s full curing before subsequent layers are applied. Low temperatures during application slow strength development; they require longer than normal for the scratch coat to achieve enough strength to receive the brown coat. Additionally, the double-back method should not be used if the substrate consists of flexible backing, such as metal lath applied over open framing.

Double-backing is only a curing method for the scratch coat and does not relieve the applicator from properly curing the brown coat. Following the double-back method, the brown coat should be protected from direct sun and wind exposure and the surface should be misted as previously detailed.

Conclusion

Enforcing project specifications is difficult unless the moist-curing language is strong. It is recommended to include the following requirements, in addition to thorough drawings and specifications for proper stucco and accessory product selection and installation.

- Provide sufficient external moisture for each coat by moist-curing to permit cementitious materials’ continuous hydration. (The most effective procedure for curing and time between coats depend on climatic and job conditions. At a minimum, mist the scratch and brown coats at the start and again at the end of each calendar day.)

- If there is a delay before applying the brown coat, moist-cure the scratch coat daily until the brown coat is applied.

- Moist-cure the brown coat for a minimum of two consecutive days.

- Immediately before applying the finish coat, moisten the base coat to control absorption during the finish’s application and tooling. Finish coat should be moist cured for a minimum of two days. For proprietary systems, manufacturer curing recommendations should be followed.

If the contract documents include control joints drawn at regular intervals, the provisions laid out in ASTM C926 and C1063, Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-based Plaster, are strictly adhered to during construction and the stucco is properly moist cured, it is reasonable to believe the stucco application will not crack and with proper maintenance will last more than 100 years. (See the article, “How Long Does Stucco Last?” posted on PCA’s website, www.cement.org.)

Nickie Ramm, EIT, has bachelor’s and master’s degrees in architectural engineering from the University of Texas at Austin. She is a project engineer at Building Diagnostics Inc., where she specializes in failure investigation, remedial design, architectural peer review, new construction monitoring, and diagnostic testing for building envelope systems. Ramm also participates in the company’s research group, The Durability Lab, which researches and tests the durability of building components, identifying factors causing premature failure. She can be reached via e-mail at nramm@buildingdx.com.