The goal of tapered roof insulation systems is to eliminate ponding water on a membrane when the roof deck alone does not provide adequate slope. This can be an especially effective strategy for existing buildings that lack proper roof slope and where achieving the desired slope through structural changes is impractical or cost prohibitive. A properly designed tapered roof insulation system not only supports the roof system and adds necessary R-value to the roof, but it can improve the performance and extend the life of the roof system by providing the required drainage. Due to its wide use in low-slope roofing application, tapered polyiso insulation systems offer numerous benefits in addition to providing positive drainage: high R-value, versatility, and customization to accommodate project-by-project complexity, compatibility with other roof system components, and ease of installation.

Slope and drainage requirements in building codes

When reviewing the options available for achieving the required slope in a roof system, designers have several choices. According to the National Roofing Contractors Association (NRCA), adequate slope can be achieved by sloping the structural framing or deck, designing a tapered insulation system, using an insulating fill that can be sloped to drain, or a combination of the above in conjunction with proper location of roof drains, scuppers and gutters.

Chapters 11 and 15 of the International Building Code (IBC) contain the critical requirements for determining roof drainage. When tapered insulation systems are selected, attention should also be paid to the IECC. It establishes minimum insulation requirements for roof systems installed on commercial buildings with insulation entirely above the roof deck. The thermal performance of tapered insulation systems can contribute to designs meeting or exceeding these minimum insulation requirements.

In the publication of the 2021 IECC, the requirements for calculating the R-value or U-factor contributions of tapered insulation systems have been clarified. The relevant section for U-factor calculations is C402.1.4.1.1 and the corresponding section for R-value calculations is C402.2.1.1. Section C402.1.4.1.1 deals with U-factor calculations and Section C402.2.1.1 deals with R-value calculations. For example, to determine R-value, the new 2021 IECC language states that the calculation shall use the average thickness in inches along with the material R-value-per-inch. This provides clear guidance on R-value calculation and should allow for the thermal performance of tapered systems to more easily meet energy code compliance requirements. Additionally, the 2021 IECC states that the minimum thickness of above-deck roof insulation at its lowest point shall not be less than 25.4 mm (1 in.). This provides helpful guidance when designing tapered insulation system thicknesses around gutters, drains and scuppers.

Design considerations for tapered insulation systems

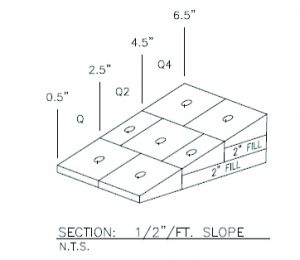

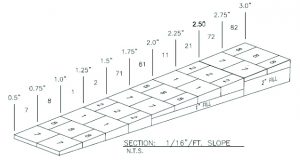

Proper design and installation are critical to the effective performance of any product, including tapered polyiso insulation systems. Tapered polyiso is manufactured in 1.2 x 1.2-m (4 x 4-ft) or 1.2 x 2.4-m (4 x 8-ft) panels that change thicknesses across the width of the board from the low edge to the high edge on the opposing sides. The standard slopes for tapered insulation are 3.18, 6.35, and 12.7 mm (0.13, 0.25, and 0.5 in.) per ft to accommodate specific project requirements. However, tapered insulation panels with slopes as low as 1.52 mm (0.06 in.) and other alternative slopes 4.78 and 9.53 mm (0.19 and 0.38 in.) per ft can be ordered to accommodate unique field conditions. The common minimum manufactured thickness of tapered polyiso insulation board at its low edge is 25.4 mm (1 in.) and the common maximum thickness at the high edge is 114.3 mm (4.5 in.). Other product thicknesses (both minimum and maximum) may be available from certain polyiso manufacturers.

The design of each tapered insulation system is governed by the footprint and complexity of the roof, including the slope of the roof deck, configuration of roof drains (primary and secondary), scuppers, gutters, and drip edges. Additionally, roof structures, height of parapet walls, expansion joints, curbs, through-wall flashings, and any other elements that may obstruct water management also need to be considered in the design phase. The tapered insulation system will be lowest at internal drains, scuppers, gutters, and drip edges, and will slope upward away from these features.

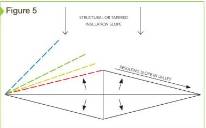

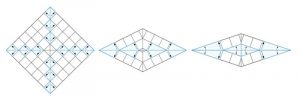

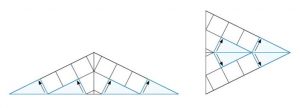

The primary goal of a tapered insulation system is to move water to the specified drainage points. Two-way (two-directional slope) or four-way (four-directional slope) systems are the most common designs. A two-way tapered insulation system is commonly used on roofs where multiple drains are in straight lines. In this scenario, there is a continuous low point between the drains, and it often extends to the parapet walls. Crickets sit in between the drains and between the building or parapet walls and the drains (Figure 1).

Low slope roofs benefit from a four-way tapered insulation system to move water to the drainage points and off of the roof. Industry professionals often recommend this as the most efficient way to manage roof drainage. In this scenario with a drain located in the center of the drainage area, water funnels in from the higher perimeter edges on all four sides (Figure 2, page 43). Variations of two- and four-way systems exist to accommodate complexities in the field. One-directional slope and three-directional slope tapered systems can also be used to direct water to gutters, drip edges and scuppers.