Increasing productivity with modular building

by Catherine Howlett | November 1, 2012 10:35 am

[1]HORIZONS

[1]HORIZONS

Tom Hardiman, CAE

Despite the construction industry’s immense size and importance to the U. S. economy, its productivity—the quality, pace, and cost of which buildings and infrastructure are constructed—is thought by some to be lagging. New industry research shows one potential solution to improve this is the expanded use of prefabrication and modularization.

These are construction processes that have been used for generations, dating as far back as Egypt’s Great Pyramids. Over the past century, they have been viewed by many in the United States as cheap and low in quality. However, recent advances in technologies and innovation both at home and overseas are changing that image. Three primary reasons for modular being seen as a process to improve construction efficiency are:

- increased use of building information modeling (BIM) technologies;

- growing emphasis on green building; and

- owner demand for better quality and more cost controls.

BIM

The National Institute of Standards and Technology (NIST) estimates $15.8 billion is lost annually by the U.S. construction industry because of:

- a lack of standardization;

- continued paper-based business practices;

- inconsistent technology adoption among stakeholders; and

- the highly fragmented nature of the industry.

[2]

[2]Photo courtesy Triumph Modular

One solution NIST[3] recommends is the widespread deployment and adoption of building information modeling.

BIM uses 3-D, real-time, dynamic building modeling software to customize different elements within structures before they are built—increasing the productivity of the design-build process. Modular construction works well with BIM because it uses an assembly-line approach in a controlled factory environment where the process already integrates systems, materials, and labor flow.

The efficiencies of integrating modular construction on a project are capitalized on when implemented from the beginning of the design-build process. Like BIM, the offsite construction process encourages all involved in the project to collaborate at the beginning stages—raising the likelihood of accurate, buildable specifications being implemented and avoiding rework toward the end of the build cycle.

In 2011, McGraw-Hill Construction (MHC) released a report, “Prefabrication and Modularization: Increasing Productivity in the Construction Industry,” which said BIM’s growing popularity will help the modular industry gain traction, and the combination of the two is ideal to improve productivity on a project:

- BIM helps enable prefabrication of tightly integrated [mechanical/electrical/plumbing] MEP systems, allowing designers to maximize space for other uses in high-tech buildings like hospitals. (For more, see McGraw-Hill Construction’s [MHC’s] SmartMarket Report[4], “Prefabrication and Modularization: Increasing Productivity in the Construction Industry.”)

- In a recent study about BIM’s use on green projects, MHC found:

- using BIM on prefab on more than one-quarter of their projects is expected to increase by 20 percent;

- 77 percent of contractors surveyed believed BIM would allow them to use prefab on larger, more complex projects in the future; and

- construction professionals who use BIM on green projects are more likely to do model-driven prefab than non-green BIM users. (See MHC’s SmartMarket Report[5], “Green BIM: How Building Information Modeling is Contributing to Green Design and Construction.”)

‘Green’ building

With all the standards, codes, and rating systems for green building being implemented and adopted—such as International Green Construction Code (IgCC) and Leadership in Energy and Environmental Design (LEED)—it has never been more important to build with environmental conservation in mind.

MHC’s Green Outlook 2011 report shows the rising popularity of green building––the market has grown 50 percent in two years despite the recession. In 2010, pursuing LEED was mentioned in 71 percent of all projects valued at more than $50 million. The McGraw-Hill research also shows:

- green building provides reduced operating costs—13.6 percent for new buildings and 8.5 percent for retrofits;

- growth in building values—10.9 percent for new structures and 6.8 percent for retrofits; and

- an increase in return on investment (ROI) 9.9 percent for new facilities and 19.2 percent for retrofits[6].

This creates another key opportunity for modular construction to be more widely adopted. Not only does the offsite, controlled environment make modular ideal for BIM, but it also makes it a more material- and resource-efficient process.

Modular construction can also contribute toward LEED requirements in any category that site-built construction can, and, in some areas, can even provide an advantage. For example, one of the great economies of modular construction is the ability to assemble repetitive units in controlled conditions. Another is to minimize waste associated with conventional construction due to weather intrusion and construction site theft. Whole modular units––largely finished before arriving at the construction site—can significantly limit construction waste generated at the site and contribute directly to waste management.

[7]

[7]Photo courtesy Pacific Mobile Structures

Modular construction capitalizes on the ability to move product in controlled manufacturing conditions and on tight inventory control and project schedules. Additionally, modular buildings are better designed for deconstruction and reuse. Structures can come apart in pieces in the same way they were created. This allows for relocation and repurposing rather than demolition, meaning less waste is sent to landfills.

Modular construction is inherently waste-conscious and the resource efficiency of the construction process provides an advantage in meeting LEED requirements in the Materials and Resources (MR) category.

LEED rewards projects for recognizing where materials come from, how they are used onsite, whether they are salvaged during renovations, and how the residual waste stream is managed. Special recognition is given to using existing buildings and materials with recycled content.

The offsite, factory-controlled construction process also provides modular manufacturers with other advantages in meeting the LEED requirements. It can have minimal site impact when delivered carefully and strategically with respect to site constraints qualifying projects for credits under Sustainable Sites (SS). The tight building of the modular construction allows for superior energy conservation and indoor air quality (IAQ), qualifying modular projects for credits in the categories of Indoor Environmental Quality (EQ) and Energy and Atmosphere (EA). (See “Modular Building and the USGBC’s LEED[8]: Version 3.0 2009 Building Rating System,” by Modular Building Institute [MBI].)

Better quality and cost controls

The benefits of creating superior buildings that are not just environmentally responsible and energy-efficient, but also save time and money, are particularly appealing in the current economic climate.

With modular construction, modules can be assembled offsite in a controlled manufacturing environment at the same time, or even before sitework has begun. Trade coordination occurring at the factory also improves efficiency. No longer do electricians and plumbers have to wait until the entire building is framed in to begin work, and no longer does the first floor need to be completed before beginning on the second.

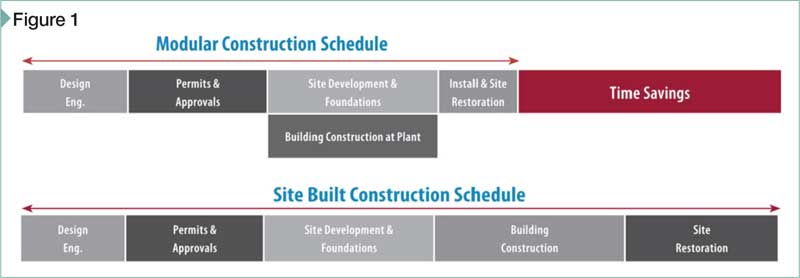

[9]

[9]Image courtesy Modular Building Institute

With modular construction, walls, floors, ceilings, and rafters are all built at the same time, then brought together in the same factory to form a building (Figure 1). This streamlined, efficient, and accelerated construction process results in fewer labor hours needed per project, fewer trips to the site per project, and allows building owners to see a faster ROI.

Due to the simultaneous process of creating modules in a factory at the same time sitework is occurring, 66 percent of respondents for MHC’s modular report say project schedules are decreased and 65 percent report project budgets are decreased.

NIST also acknowledges the advantages of the modular construction process and identifies it as a breakthrough to improve the overall efficiency and productivity of the construction industry:

Manufacturing building components[10] offsite provides for more controlled conditions and allows for improved quality and precision in the fabrication of the component…The greater use and deployment of these techniques (if used appropriately) can result in lower project costs, shorter schedules, improved quality, more efficient use of labor and materials, and improved worker safety.

Modular facilities are built with the same materials as site construction to meet or exceed all building codes and architectural specifications. Additionally, they can be highly customizable. Several inspections are made to modular building during the construction process, reducing potential risks associated with poor facility performance. It is an effective solution for various markets and can provide great quality control.

Conclusion

The inefficiencies of the construction industry, which have predominately been driven by traditional construction, are well-documented. Recent research also supports the fact offsite construction improves productivity on a project and increased adoption of these methods helps the industry grow. Modular construction is an important process to provide inherently green benefits and a technique to cut the time and cost of construction and to complete projects more safely with fewer workers.

The growing popularity of building information modeling technologies, green building, and the increasing need to save money and time on quality buildings are fueling the trend. As summarized in the MHC report, the modular construction process has the unique ability to bring together BIM, sustainable building practices, and lean manufacturing techniques to have an exponential increase on construction productivity.

Tom Hardiman, CAE, is the executive director of the Modular Building Institute (MBI)––the international non-profit trade association for commercial modular construction. He has worked in the construction association industry for 13 years. Hardiman can be reached at tom@modular.org[11].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/11/tom-e1456155710632.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/11/horizons_Harvard.jpg

- NIST: http://www.nap.edu/catalog/12717.html

- SmartMarket Report: http://www.construction.com/market_research/FreeReport/PrefabSMR

- SmartMarket Report: http://www.construction.com/market_research/FreeReport/GreenBIM

- retrofits: http://www.analyticsstore.construction.com/index.php/green-outlook-2011-green-trends-driving-growth.html

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/11/horizons_KirkhamChildcare.jpg

- Modular Building and the USGBC’s LEED: http://modular.org/marketing/documents/Modular_09V3LEED.pdf

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2012/11/CS_Nov2012_HR-19-fig1.jpg

- building components: http://www.nap.edu/catalog/12717.html

- tom@modular.org: mailto:tom@modular.org

Source URL: https://www.constructionspecifier.com/increasing-productivity-with-modular-building/