Indent Fracturing of Stone Tile: What is it… and how can it be prevented?

Absorption and rate of absorption of stone tile

The extent of indent fractures increased with increased tile water absorption (and rate thereof), as shown in Figure 2. Of the four stone types exhibiting the most frequent occurrence of indent fractures, two had approximately 14 times greater absorption—when tested in accordance with ASTM C97, Standard Test Methods for Absorption and Bulk Specific Gravity of Dimension Stone—than the others. The stone types with greater absorption had approximately two times greater frequency of indent fractures.

Stone tiles with higher total absorption were also found to have higher rates when partially immersed in water. The more-absorbent stone types had moisture first observed on the top surface of tiles in less than 20 minutes, while the less-absorbent ones did not have moisture after several days of monitoring.

Warping and elongation of stone tile due to water exposure

Testing showed stone types exhibiting a higher frequency of indent fractures in-situ generally display greater warp and elongation when immersed in water than stone types experiencing less-frequent indent fractures. The four stone types with the most frequent occurrence of indent fractures showed approximately twice the measured warp and elongation of the three stone types with less-frequent occurrence. This strongly indicates stone-tile types with greater moisture expansion are likely to be subjected to greater internal stresses and potential for cracking after mortar bond develops and the stone attempts to return to its pre-wet and preset size. However, the measured warp and elongation do not correlate precisely with observed indent fracture occurrence, as other factors also contribute.

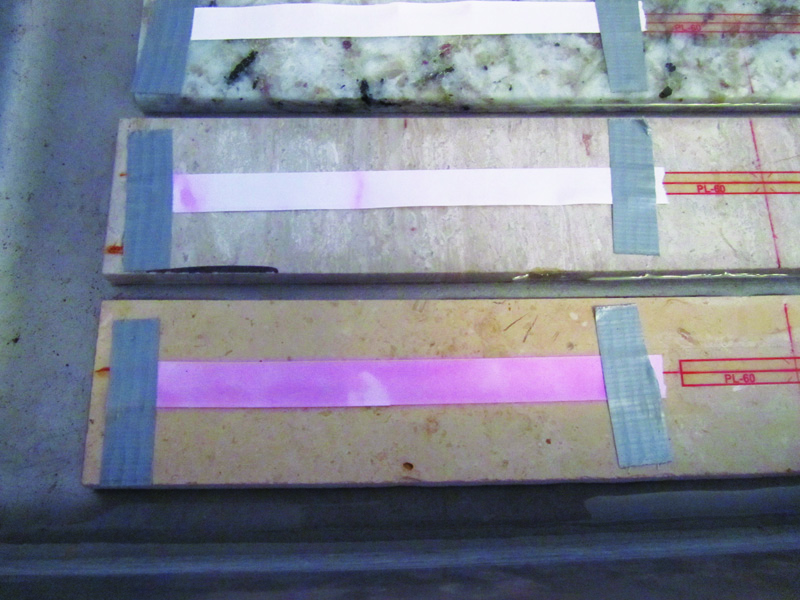

All other factors being equal, an assembly with stone tile that is more moisture-sensitive (i.e. greater warp and elongation upon wetting) has greater potential for cracking that may lead to indent fractures after bond with the setting mortar has developed. Figure 3 shows a partially immersed specimen being monitored for warp and elongation.

Mortar shrinkage

After the stone tile and mortar bond, a greater magnitude of mortar shrinkage will result in greater applied forces and stress to the tile, increasing the potential for tile cracking and indent fractures. Testing (in accordance with ASTM C596, Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement) showed there are differences in the rate and magnitude of mortar drying shrinkage of three different types of commonly used thin-set mortar during curing at 50 percent relative humidity (RH). Depending on the mortar type, approximately 80 to 90 percent of the 28-day shrinkage occurred within the first week of curing. While most mortar shrinkage occurs in the first seven days, continued shrinkage may sometimes result in the later appearance of indent fractures.

Further, shrinkage cracks are less likely to develop in mortar prevented from curing rapidly, as shown by comparative evaluation of sealed and unsealed thin-set mortar applications. Based on this, the rate of mortar shrinkage and potential for shrinkage cracks may be significantly reduced by the presence of the tile, particularly impervious ones that absorb little water from the setting mortar. Testing performed on mortar with two different water contents showed initial moisture content does not necessarily affect mortar shrinkage, though it may affect the moisture expansion of the tile, as more water would be available for tiles to absorb.

Flexible substrate materials

Where mortar is set on a flexible substrate, the flexible material may provide only minimal restraint against shrinkage of the setting mortar, leaving the job primarily to the stone tile. Where restraint is insufficient, the setting mortar will crack upon curing. Testing showed the tensile modulus of a sound-attenuation mat was insufficient to significantly restrain shrinkage of the setting mortar, and was also significantly lower (i.e. more elastic) than elements such as the stone tile, mortar, and concrete substrate (Figure 4).