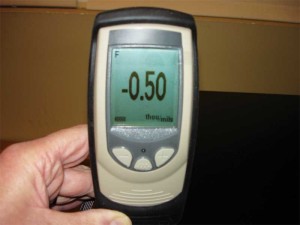

Light meter

As their name suggests, light meters measure light at workstations, stairwells, and means of egress. Calibrated for imperial and metric (i.e. footcandles and lux), they should have settings for the type of light source—daylight/tungsten, sodium, mercury, fluorescent, or incandescent.

Glass analyzer

These devices measure ultraviolet (UV) transmission, visible light transmission (VLT), infrared, and solar heat gain coefficient (SHGC) to evaluate performance of glass systems.

pH tester

Primarily used to check the pH of cementitious materials before painting and for potential efflorescence, a pH tester can be quite invaluable to some professionals.

Pressure gauge

The pressure gauge is often used to check the opening force of doors to ensure compliance with the Americans with Disabilities Act (ADA). They tend to be calibrated in pounds per square foot.

Crack monitor

These devices determine the stability of cracks and fissures.

Rare earth magnets

Extremely powerful magnets, these round tools (16 to 19 mm [5/8 to 3/4 in.] in diameter) are used to locate ferrous fasteners in wood floors. (Refer to this author’s two-part article, “Mysteries of Moisture Meters,” in the May and June 2006 issues of The Construction Specifier.)

Sports floor and pile tester

Calibrated in inches and millimeters, these tools measure thickness of installed resilient athletic floorcovering and carpet pile.

Frame gauge

A frame gauge measures width, squareness, and plumb of door installations. Essentially, it picks up where the level leaves off.

Calipers

Calipers measure thickness of sheet goods such as metal and membrane, also doubling as a depth gauge. The minimum capacity should be 152 mm (6 in.).

Insulation depth gauge

This tool confirms thickness of insulation and fireproofing after installation.

Joint/seam probe

These probes check the presence of sealant in sheet metal joints and for openings in seams of roof membrane.

Roof core

Taking a core sample of an existing roof is an important and relatively simple procedure. It involves taking cores of the complete roof system to determine the components and construction. As it is clearly a destructive test, it should be performed by skilled roofing professionals with proper equipment and proper materials readily available to make repairs promptly. Some owners may become a little antsy if someone cuts a two-inch hole in their roof and may want to ensure the person cutting the hole has the equipment, materials, and experience to make proper repairs after the core is removed. Also, there may be some liability involved should leaks occur at the core location.

Thermal imaging

For years, thermography has been used successfully in the medical profession (e.g. ultrasound), but it is now becoming in vogue for the construction industry. Since prices range from approximately $1500 for an entry-level camera to well over $12,000 for advanced models, they are likely the most expensive—and complex—item in the toolbox.

Unlike most test instruments that provide an instant quantitative value or a specific location (e.g. 16.7 percent moisture content in the wood sills), the typical thermal imaging camera gives an image of the object highlighted in transitioning color shades of red, orange, yellow, green, and blue. Each hue represents a temperature that is displayed as a side bar on the thermal imaging display.

The primary use of thermal imaging is identifying thermal leaks in the building assembly. It identifies problem areas for further investigation and, since it can cover a large area at one time, it generates more information much faster. Contrary to common perceptions of thermal imaging, the technology does not provide a cause or a solution for problems. For instance, a thermal image can show heat escaping from a wall assembly. However, it takes further analysis to determine whether the problem is wet or missing insulation, leaking plumbing, openings in the wall assembly, inadequate or poorly performing materials, or poor construction. Other applications include locating ungrouted cells and delaminated concrete, but it will not reliably locate missing rebar.

Accurate and successful thermography requires a good understanding of the principles of heat transfer and, when used for construction, an understanding of construction assemblies and building science. Just as it takes an experienced radiologist to interpret X-rays, it takes a trained and experienced thermographer to interpret the pictures. Since the camera and certification represent a significant investment, careful thought regarding equipment and training should be made before making the plunge.