Installing bollards into existing concrete

by sadia_badhon | July 8, 2020 10:48 am

by Arwen Brenneman

[1]

[1]Over the past few decades, construction has taken an increased role in public safety and security. “Use at your own risk” is still true, but good site design is expected to mitigate those risks. Bollards have taken a larger role in offering protection or guidance. The Federal Emergency Management Agency (FEMA) guidelines, widely adopted by civic institutions in several countries, offer ways to prevent terrorist and ram-raid thefts through perimeter security. Popularized in Sweden, vision-zero guidelines, offer environmental strategies to decrease traffic injury and fatality.

Safety, security, and asset protection strategies may call for bollards, but the little posts are often designed to blend in. Due to their short stature and small footprint, they can be easy to forget. Bollards are also the sort of item that may be changed late in the game for aesthetic or budgetary reasons.

Whether the bollards were initially forgotten, or whether large orders or changes to design mean order lead times are longer than expected, last-minute additions can cause real stress. If the project timeline is set back, the budget can be threatened. Project leads can feel torn between holding off on pouring concrete or ripping up existing sidewalk—neither seem like a great option.

Fortunately, bollards can be installed into existing concrete, saving both money and time. Procedures for this installation depend on whether the bollards need to be impact-protective or just serve as guideposts.

Installation of traffic guidance bollards

Although impact-protective and anti-terrorist bollards make news headlines, most bollards do not need target hardening. Traffic guidance bollards are often not impact-protective. In the case of flexible bollards, they may be chosen explicitly because they bend on impact.

[2]

[2]Removable bollards, like those beside a plaza or at the end of a loading bay, are often placed to prevent casual parking or drive-through access. Even though they are not anti-ram, they are still effective as drivers will not crash into them to get a parking space. A bolted metal bollard will cause damage to a vehicle hitting it with any speed, whether it is impact-protective or not.

Bollards are also used in pedestrian areas where impact protection is unnecessary. Decorative bollards connected with chains might structure a lineup outside a venue, protect a garden, or discourage people from cutting across the edge of a lawn.

Fortunately, installing these bollards into existing concrete does not require too many tools. For example, a drill with a masonry bit and a handful of other inexpensive supplies can do the job.

Although it is unlikely there will be utilities or pipes at the depths required for setting bollards into existing concrete, it is advisable to always check to ensure there are no underground hazards before beginning installation.

Installation using threaded steel rods

Internal threaded rods are used to help with mounting and keep the bollard plumb. Rods are commonly employed as cap or frame anchors when set into the concrete of impact-protective pipe bollards. They can also be handy as a bollard mounting.

Threaded rods are substantial, usually 6 to 25 mm (¾ to 1 in.) in diameter, and made of steel. Depending on the type of bollard, a rod can run through the bollard and be both anchor at base and place to secure the bollard cap.

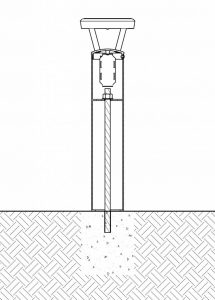

Installing bollards with adhesive

Adhesive anchors are a quick way to set a threaded rod into concrete. The upside is in speed and ease of installation. The downside is the rod will need to be drilled out if the bollard is removed.

In vehicle collisions with the bollard, it is more common for the rod to bend than snap or be pulled free. Crashes may therefore lead to drilling.

[3]

[3]This solution can be ideal for locations that may see extensive concrete rework in the future. Use an adhesive anchoring system rated or approved for use in structural concrete with ASTM E488, Standard Test Methods for Strength of Anchors in Concrete Elements; ASTM C881, Standard Specification for Epoxy-Resin-Base Bonding Systems for Concrete; and other applicable standards for location. Make sure to check the relevant transportation authorities to confirm the adhesive meets hazardous materials requirements for location.

The procedure to install with adhesive is:

- examine the bollard spacing plan and mark the precise center point of each bollard;

- adhesive anchoring systems recommend a minimum radius (often 127 mm [5 in.]) of solid concrete around the drill site;

- the solid concrete should also be equal to or greater than the diameter of the bollard;

- tap a pilot divot hole in the center of each mark to prevent the drill from drifting during boring;

- set depth control on hammer drill or rotary hammer, or mark depth on the masonry bit (usually 102 mm [4 in.] is sufficient for good adhesion, however, it is advisable to check the manufacturer’s recommendations. It is also advisable to check length of threaded rod as it must be longer than depth plus the bollard body length so it can be secured in the bollard);

- drill a hole of 3 mm (1/8 in.) greater diameter than the threaded rod;

- vacuum or blow debris from the hole;

- fill with adhesive, moving slowly from bottom to top, to prevent air pockets;

- set bollard over hole and make sure it is completely plumb;

- lower rod through the bollard center frame, then twist it into the adhesive to achieve maximum grip strength; and

- let cure for at least 45 minutes before finishing installation.

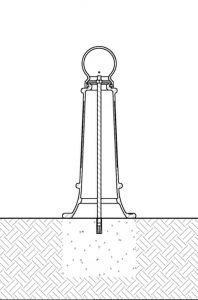

Installing bollards with drop-in inserts

Drop-in concrete inserts require slightly more time to install than adhesive anchors, but they are easier to handle on removal. The drop-in insert is threaded on the inside to match the threaded rod. Should the bollard be removed, the rod can be unscrewed from the insert simply, rather than needing to be dug out. Concrete patching solution can be applied over the insert. (If the anchor must be removed, a bolt breaker or grinder is used to remove the drop-in insert before patching, making the procedure as time consuming as adhesive removal.)

[4]

[4]A concrete insert works like a wall anchor to provide grip. When installed using a setting tool or flat-end punch, they expand inside the concrete hole to create strong, loadbearing mountings. A common application for these inserts is in ceilings in order to bear the weight of hanging hardware.

Plated steel inserts are a good choice for outdoor applications.

To install bollards with concrete inserts:

- examine the bollard spacing plan then mark the precise center point of each bollard;

- concrete anchoring systems often recommend a minimum radius of solid concrete around the drill site and between anchor points (check specifications for the inserts being used, they are often 178 to 229 mm [7 to 9 in.] apart);

- for optimal strength, the concrete should be at least 152 mm (6 in.) deep;

- the bollard base should rest completely on the concrete;

- tap a pilot divot hole in the center of each mark to prevent the drill from drifting during boring;

- the concrete insert used will depend on the size of the threaded rod (a 19-mm [3/4-in.] rod will require a 19-mm insert, and most 19-mm inserts need a 25-mm masonry bit, so it is best to check the manufacturer’s directions for the necessary hole diameter.);

- set control on hammer drill or rotary hammer to proper depth (check drop-in insert manufacturer’s recommendation and ensure that the depth plus the length of the bollard body is less than the length of the rod);

- vacuum or blow debris from the hole;

- drop the concrete insert in and ensure it is flush with the concrete surface and completely level;

- hammer the insert into place using the setting tool or a flat end punch;

- set bollard over hole and make sure it is completely plumb;

- lower rod through the bollard center frame then twist it into the insert; and

- finish installation.

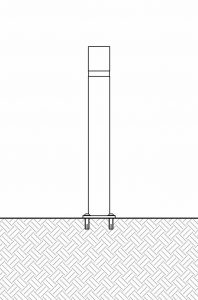

Flanged base bolt-down bollards

Another way to install bollards into existing concrete is to purchase bollards with a metal plate or flange at the base. Flanged bollards generally come with square or circular base plates with two or three bolt holes.

Bolts, rather than threaded rods, affix these models of bollards. As with the threaded rod models, drop-in inserts are needed to securely bolt the bollards to the floor.

To bolt down bollards:

- use 13-mm [½-in.] head bolts, 13-mm washers, and 13-mm drop-in inserts;

- examine the bollard spacing plan then mark the precise center point of each bollard;

- concrete anchoring systems often recommend a minimum radius of solid concrete around the drill site, between anchor points (check specifications for the inserts being used: the holes in the flange may be closer than this minimum radius, but individual bollards should be spaced farther apart);

- for optimal strength, the concrete should be at least 152-mm deep;

- the bollard base should rest completely on the concrete;

- keep the bollard in its packaging for as long as possible;

- place the bollard over the center point, then adjust the orientation of the bollard or flange to the preferred position (once the bollard has been bolted down, it will be immovable);

- mark the bolt holes with chalk to create drill markings;

- tap a pilot divot hole in the center of each mark to prevent the drill from drifting during boring;

- drill holes (for 13 mm hardware, drill 16-mm [5/8-in.] diameter and 50-mm [2-in.] depth, and mark masonry bit at 50 mm or use depth control);

- vacuum or blow debris from the hole;

- drop the concrete inserts in and ensure they are flush with the concrete surface and completely level;

- hammer the inserts into place using the setting tool or a flat end punch;

- set bollard over holes and make sure it is completely plumb;

- place washers over the holes in the bollard and set bolts into place then tighten evenly, in a cycle; and

- finish installation.

[5]

[5]Lighting bollards and trenching

Lighting bollards that need an electrical grid usually require expensive trenching and sometimes need utility boxes. If one is looking for a less expensive option into existing concrete, solar bollards can drastically reduce costs.

For solar lighting bollards to be a feasible solution they must not be permanently shaded. However, even in dark or northern climates, intelligent solar bollards with light-adaptive profiles can work by conserving energy when the light is low by reducing output or only coming on during programmed hours of operation.

Solar bollards can also be interspersed with companion AC bollards, installed where trenching or electrical output will be high cost for little value. Light bollards can usually be installed through either threaded rod or bolt-down options, as well as being installed in new concrete via embedding.

Impact-protective bollards in existing concrete

For places with existing concrete, or with no concrete at all, it is possible to ‘core and pour’ impact-protective steel and concrete bollards. These simple impact-protective bollards —often seen in parking lots, near drive-through windows, and around utility boxes—are not rated by major standards companies. This is, in part, due to installation factors at the site. How deep are they set? What is the substrate like? How thick is the concrete? Still, when they are properly installed, they offer protective power against crashes.

[6]

[6]The installation of impact-protective bollards requires a core drilling rig and an auger or post-hole digger.

To core-and-pour a security bollard:

- check for underground utilities, wires, and other hazards;

- research the frost line depth in the area as the bollard’s foot must be placed below this line;

- one may require permits depending on their area;

- clean the surface of the concrete with brook or pressure washer;

- mark the center point of each bollard from the site plans;

- center core drill over the mark and use to remove concrete (the diameter of the hole should be at least 50 mm larger at all points from the bollard [e.g. if the bollard is 152-mm round in diameter, the cored hole should be 254-mm round]);

- when the concrete layer is removed, use an auger or a post hole digger to dig below the frost line;

- using well-mixed concrete the texture of moldable clay, fill the hole until it is level with the surface grade;

- set pipe bollard over the hole and turn and push down until bollard reaches bottom of hole and ensure the bollard is plumb by using a level—when the concrete is cured the bollard cannot be adjusted;

- fill the bollard to the top with concrete;

- form a rounded concrete cap or embed place bollard cap if not planning to cover the bollard;

- clean surface of bollard of excess concrete before it cures; and

- full curing will take two to three days.

Options for new concrete

These options give a crew some flexibility in adding bollards to a site. However, there are some options that are impossible without new concrete such as:

- anchor castings for threaded rod installation;

- anti-ram or anti-terrorist bollard systems crash-rated by a standards agency;

- retractable bollards with below-grade receivers (those with hydraulic systems will need substantial trench dug for installation); and

- mountings for removable bollards which sit flush with the grade.

Finding value in choice of bollard

Bollards seem straightforward: choose a decorative traffic post, and you are done. Yet, several factors in bollard choice can affect the bottom-line. Installation is one of them. The type of bollard is another. Some bollards can do double- or triple-duty—offering traffic guidance, bike parking, and solar lighting all-in-one, for example. Creating a site plan with this flexibility in mind can also help bring a project in on-time and on-budget. Though bollards are understated, they bring a lot of value to a site.

[7]Arwen Brenneman is the brand writer for Reliance Foundry[8], a leading manufacturer and distributor of bollards, hardscape, and metal castings across North America, which means she regularly writes about the diverse fields of metallurgy, water management, urban planning, and construction. Brenneman can be reached via e-mail at arwen@reliance-foundry.com[9].

[7]Arwen Brenneman is the brand writer for Reliance Foundry[8], a leading manufacturer and distributor of bollards, hardscape, and metal castings across North America, which means she regularly writes about the diverse fields of metallurgy, water management, urban planning, and construction. Brenneman can be reached via e-mail at arwen@reliance-foundry.com[9].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/multiuse_bollards.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/solar_adhesive_install.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/decorative_concrete_insert.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/flex_flanged_install.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/solar_lights.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/fenway_install.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/arwen_headshot.jpg

- Reliance Foundry: https://www.reliance-foundry.com/

- arwen@reliance-foundry.com: mailto:arwen@reliance-foundry.com

Source URL: https://www.constructionspecifier.com/installing-bollards-into-existing-concrete/