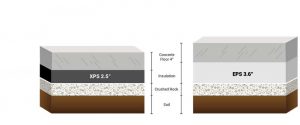

Figure 7 shows the EPS and XPS thicknesses required to obtain R10 design R-value for insulation of a below-grade concrete floor slab. For XPS insulation, 10/5.0 equals 50.8 mm (2 in.) of R5.0 XPS; adding 25 percent (2.0 + 0.5) gives an adjusted thickness of 63.5 mm (2.5 in.) for an R10 design thermal resistance using XPS. For EPS insulation, 10/4.2 equals 60.45 mm (2.38 in.) of R4.2 EPS. Adding 50 percent (2.38 +1.19) gives an adjusted thickness of 91.44 mm (3.6 in.) of EPS for R10 design thermal resistance.

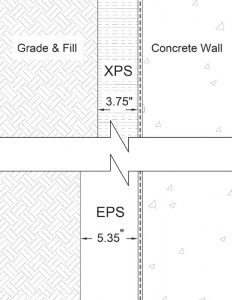

Figure 8 shows the EPS and XPS thicknesses required to obtain R15 design R-value for exterior below-grade exterior wall insulation. For XPS insulation, 15/5.0 equals 76.2 mm (3 in.) of R5.0 XPS; adding 25 percent (3.0 + 19.05 mm [0.75 in.]) gives an adjusted thickness of 95.25 mm (3.75 in.) for an R15 design thermal resistance using XPS. For EPS insulation, 15/4.2 equals 90.67 mm (3.57 in.) of R4.2 EPS. Adding 50 percent (3.57 + 1.78) gives an adjusted thickness of 135.89 mm (5.35 in.) of EPS for R20 design thermal resistance.

These thickness adjustments are based on design R-values derived from field data on polystyrene foam insulation in cold climates, as per the design standard American Society of Civil Engineers (ASCE) 32, Design and Construction of Frost-Protected Shallow Foundations.4 The user is responsible in determining whether these thickness adjustments are applicable for the local climate zone, rain exposures, and other moisture exposure from vegetation or runoff from the building rooftop. While these design values are for frost protected shallow foundations and may not apply to all climate zones, they provide some insights into how moisture absorption affects R-values in below grade applications, including basement insulations.

One must not assume foundation drainage protects thermal control. Rather, one must use the right amount of thermal control and plan for the presence of moisture leftover after drainage. Design redundancy with thermal control keeps the basement habitable.

Multipurpose insulation materials

As can be seen from the previous discussion, there are two sides to a habitable basement design strategy:

- First, keep the outside environment on the outside.

- Second, prevent condensation of interior moisture on the basement walls.

A livable basement must have a basement wall assembly that meets multiple design criteria. It needs to use wall assemblies made with multipurpose materials providing multiple lines of defense and performing multiple functions.

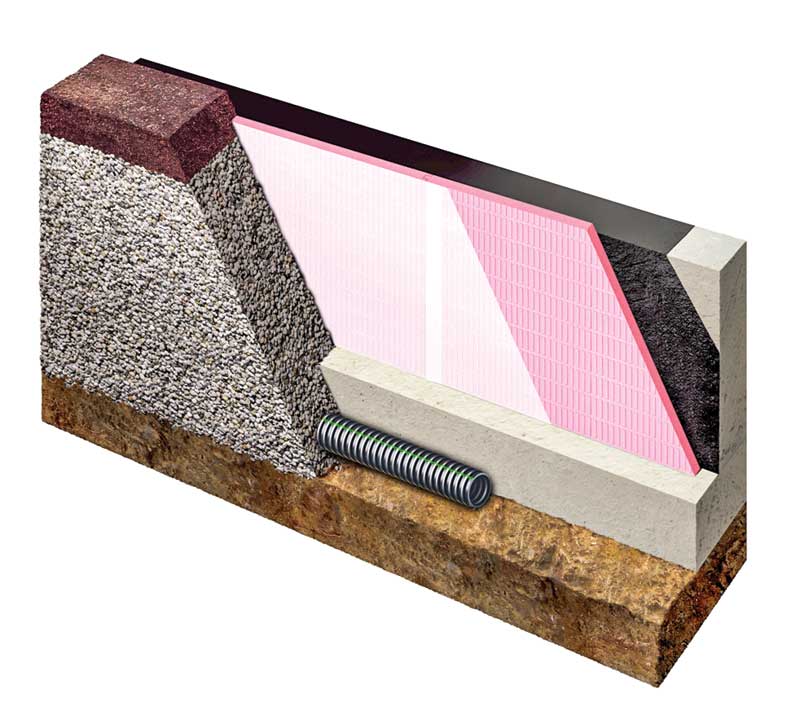

The first line of defense separates the basement wall from the outdoor environment and the second line of defense manages the moisture of the indoor environment in a way to provide a livable basement.

These multiple lines of defense need to be carefully modeled in basement wall assemblies for habitable basements that will last. The most workable moisture control strategies will include attention to the selection of quality foam insulation. The foam insulation board needs to allow for drainage, provide high R-value, resist moisture absorption, and retain R-values in below-grade applications.